Device and method for measuring oil consumption of engine

A technology for engine oil and measuring devices, applied in measuring devices, relative volume flow measurement, liquid/fluid solid measurement, etc., can solve the problems of low repeat test frequency, low precision, difficult to popularize, etc., to ensure objective accuracy, Avoid human error and ensure the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

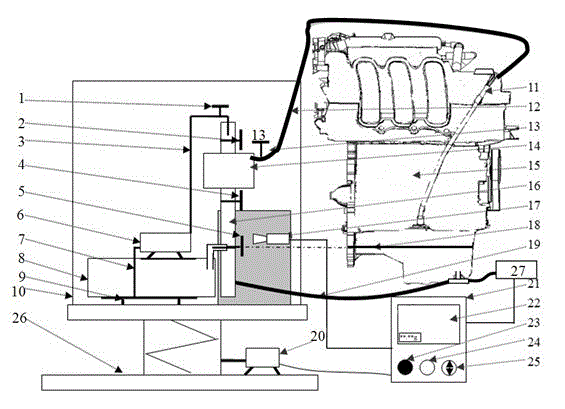

[0032] First, the structure of the engine oil consumption measurement device proposed by the invention is described, as shown in the attached figure 1 As shown, the measuring device includes a first valve 1, a second valve 2, an electronic pump oil outlet pipe 3, a third valve 4, a fourth valve 5, an electronic pump 6, an electronic pump oil inlet pipe 7, a fuel tank 8, and an electronic scale 9. Wind shield 10, ventilation pipe 12, fifth valve 13, fuel tank 14, camera 17, oil pipe 19, control unit 21, fixed lifting platform 26 and temperature measuring instrument 27. Wherein said fixed lifting platform 26 comprises base, motor 20 and lifting platform, and lifting platform is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com