A method of producing sintered NdFeB magnets

A technology of neodymium iron boron and magnets, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., and can solve problems affecting product performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Takt time T is set to 3h.

[0053] Raw materials are prepared according to the formula with a single batch weight of 200kg and a pre-performance of N44H. The raw materials are made into thin-slab steel ingots through the belt-swinging process, crushed by hydrogen explosion process, air-flow milled, and oriented and pressed under the protection of inert gas to form rough rough. Blank, put the rough blank into the material box, and fill it with inert gas for sealing protection.

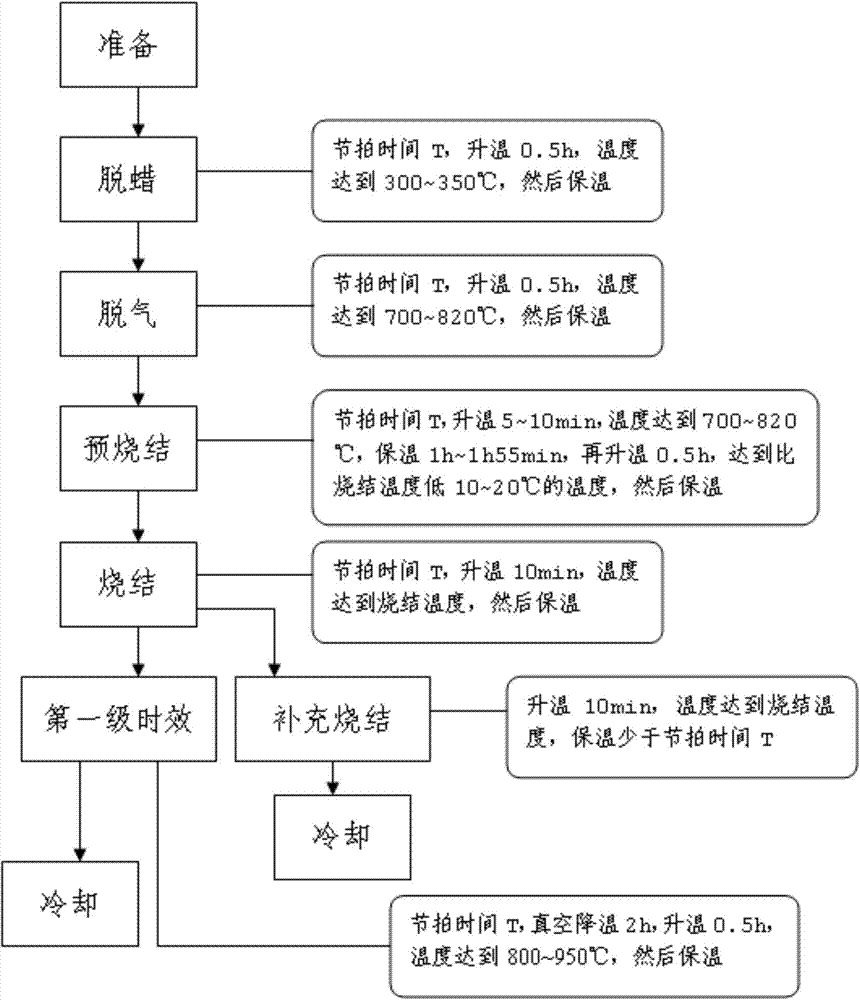

[0054] Next, the blank is sintered.

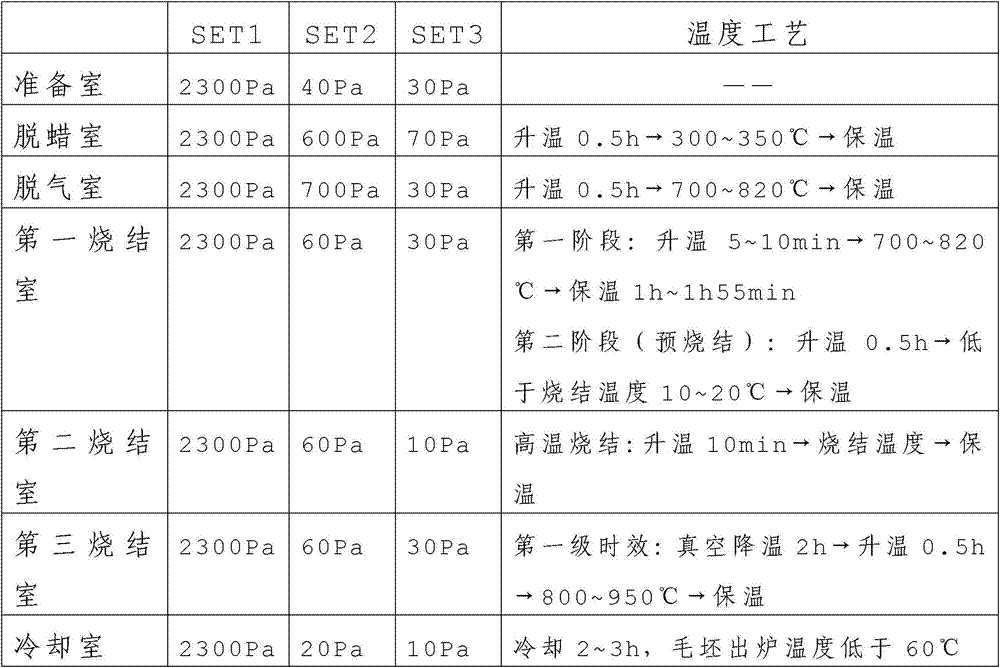

[0055] First, set the parameters of each chamber of the sintering furnace, as shown in Table 2.

[0056] Table 2

[0057]

[0058] Firstly, start the sintering furnace and enter the preparation work for automatic operation. The vacuum system of each chamber is evacuated, and the vacuum degree reaches the requirements of SET3 and other automatic operation conditions are met before entering the automatic operation state.

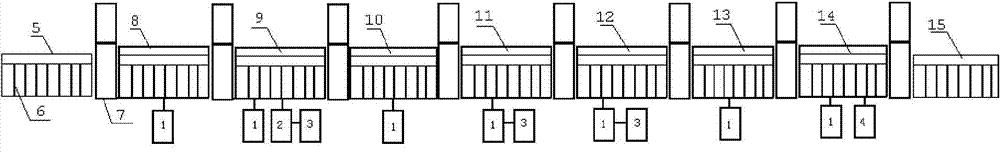

[0059] Next, put the magazine co...

Embodiment 2

[0068] Set the takt time T as 4h.

[0069] The raw materials are formulated according to the formula with a single batch weight of 300kg and pre-performance of N45SH. The raw materials are made into thin sheet steel ingots through the strip-swing process, crushed by the hydrogen explosion process, air-flow milled, and oriented and pressed under the protection of an inert gas to form a rough billet. Then put the rough blank into the material box, and fill it with inert gas for sealing protection.

[0070] Next, the blank is sintered.

[0071] First, set the parameters of each chamber of the sintering furnace, as shown in Table 3.

[0072] table 3

[0073]

[0074] The sintering process is the same as in Example 1.

[0075] During the entire implementation process, the residence time of the materials in the dewaxing chamber 9, degassing chamber 10, first sintering chamber 11, second sintering chamber 12 and third sintering chamber 13 is 4h, and the entire sintering process...

Embodiment 3

[0077] Set the takt time T as 5h.

[0078] The raw materials are prepared according to the formula with a single batch weight of 350kg and pre-performance of N45SH. The raw materials are made into thin sheet steel ingots through the belt-swinging process, crushed by hydrogen explosion process, air-flow milled, and oriented and pressed under the protection of inert gas to form rough billets. , put the rough blank into the material box, and fill it with inert gas for sealing protection.

[0079] Next, the blank is sintered.

[0080] First, set the parameters of each chamber of the sintering furnace, as shown in Table 4.

[0081] Table 4

[0082]

[0083] The sintering process is the same as in Example 1.

[0084]Throughout the implementation process, the residence time of the materials in the dewaxing chamber 9, degassing chamber 10, first sintering chamber 11, second sintering chamber 12 and third sintering chamber 13 is 5h, and the whole sintering process is smooth witho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com