Vehicle pneumatic tyre

A technology for pneumatic tires and vehicles, applied in vehicle parts, tire parts, tire treads/tread patterns, etc., can solve the problems of insufficient drainage capacity, water can not be quickly discharged, and can not be fully satisfied, etc., to achieve improvement The effect of water holding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

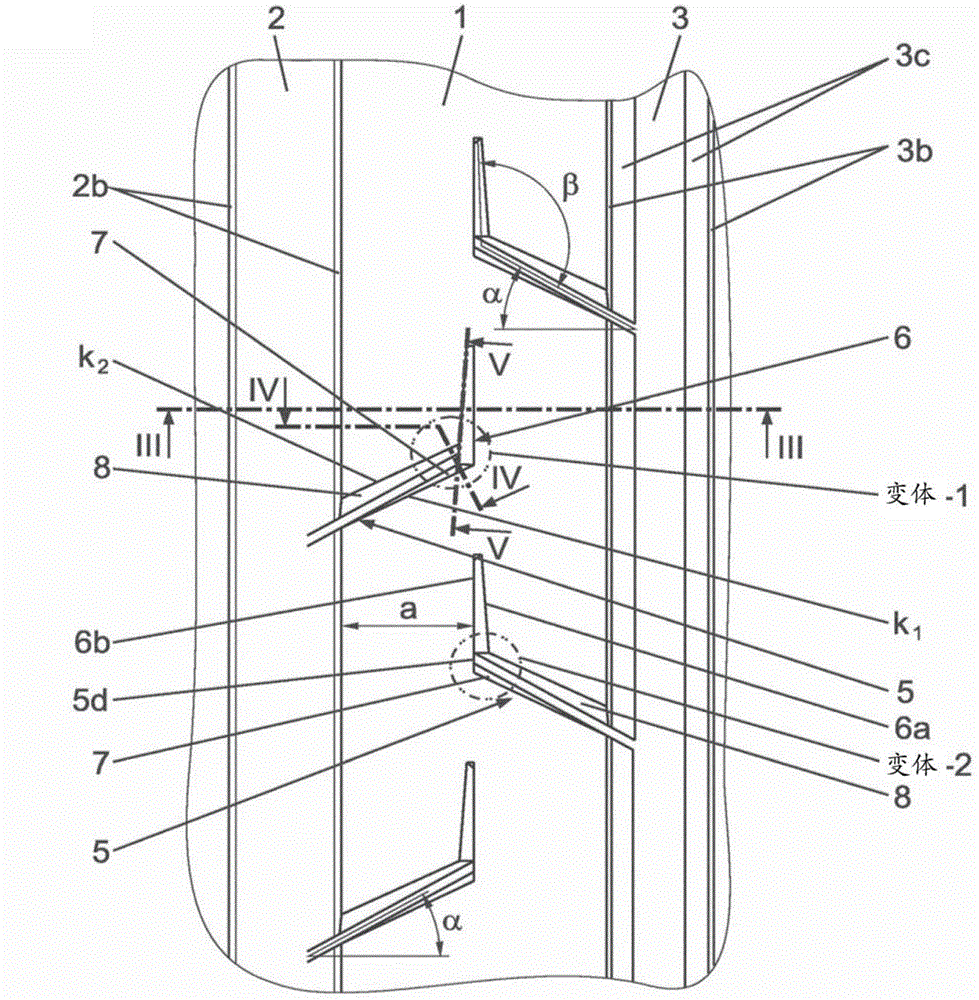

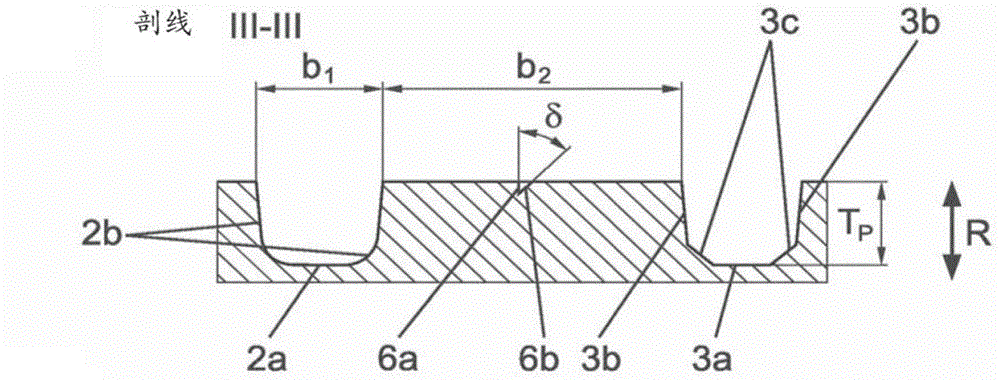

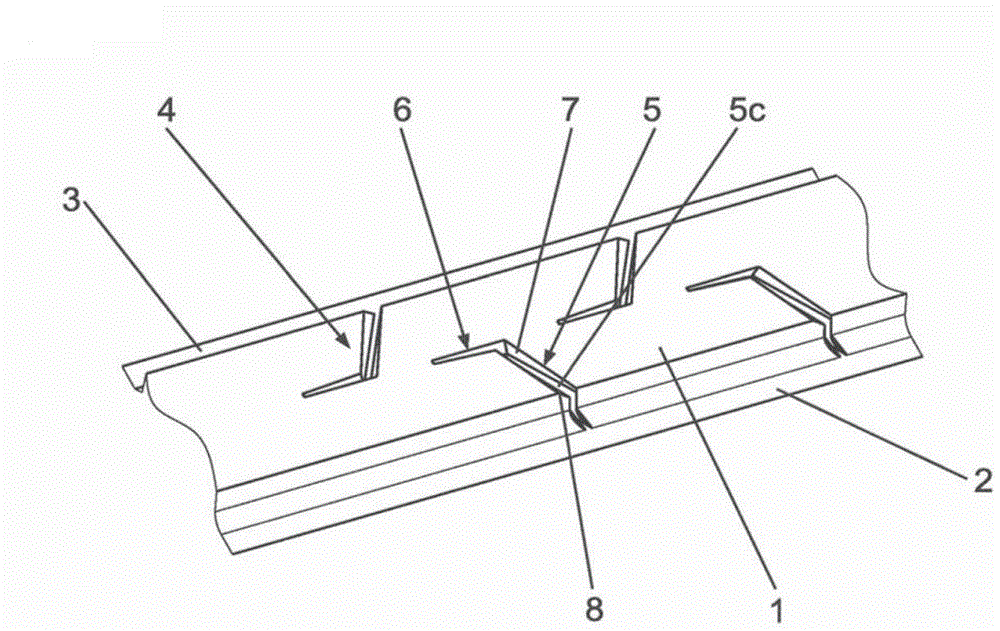

[0024] figure 1 A plan view of a circumferential section of a tread band 1 of the tread of a pneumatic vehicle tire (especially a tire for a passenger car) is shown. The tread of a pneumatic vehicle tire is usually composed of a plurality of convex treads separated from each other by circumferential grooves. These convex treads are either implemented as tread bands or circumferential grooves, or as rows of tread blocks, the latter consisting of It consists of tread blocks that are stacked in the circumferential direction and separated from each other by transverse grooves. in figure 1 The tread band 1 shown in is restricted by one circumferential groove 2, 3 each surrounding the tread in the circumferential direction, wherein the sides of these circumferential grooves 2, 3 can be connected to another structured tread area, For example, the same tread band. Such as especially in figure 2 As shown in the cross-sectional view in, each circumferential groove 2, 3 is restricted by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com