Semi-submersible platform with a stabilising fin, and offshore wave power plant incorporating such a platform

A semi-submersible platform, semi-submersible technology, applied in the fields of ocean energy power generation, engine function, engine components, etc., can solve problems such as mechanical fatigue and reduced productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

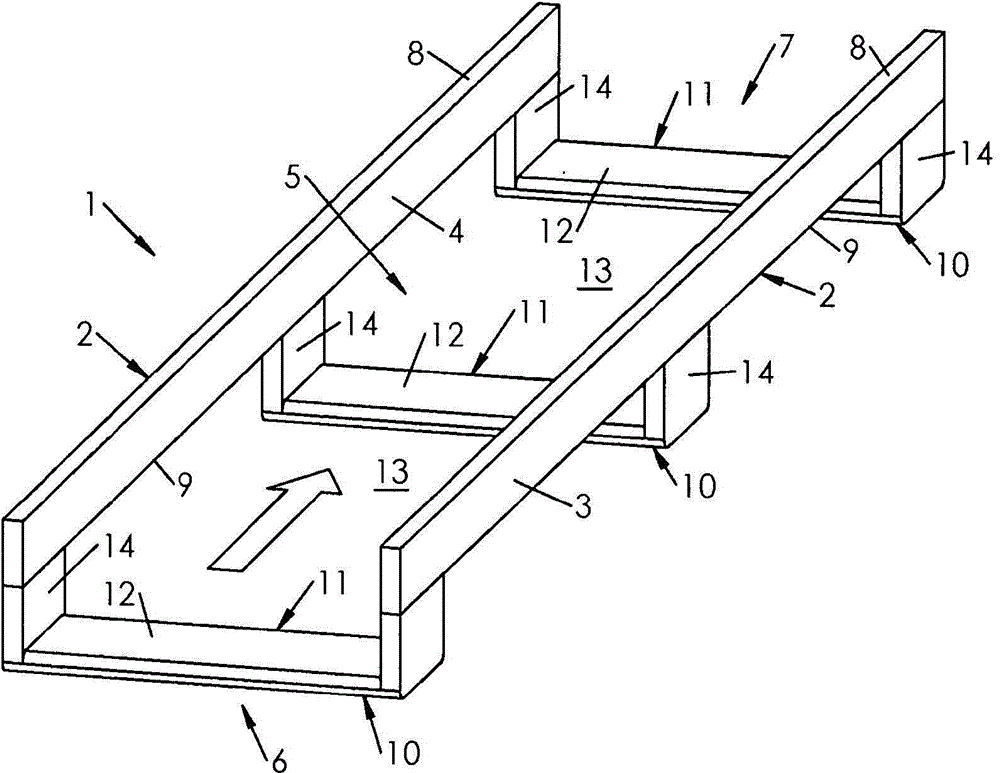

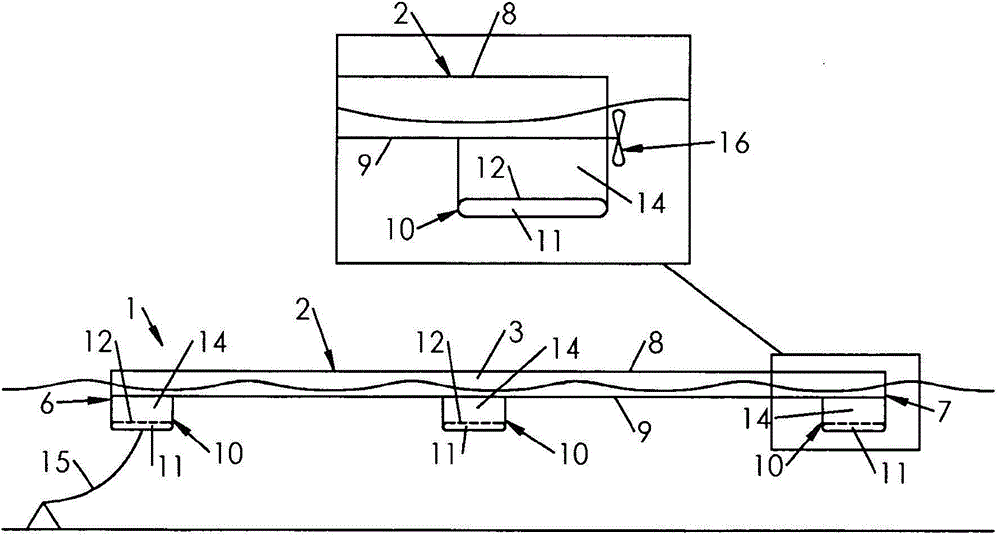

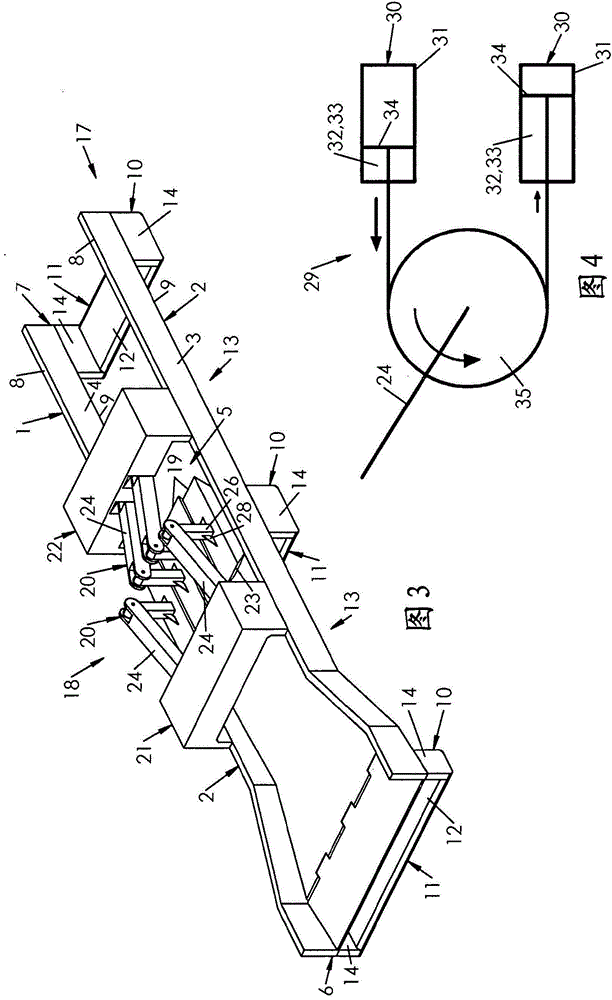

[0039] exist figure 1 The semi-submersible floating platform 1 is shown above, and the semi-submersible floating platform is used as an infrastructure for marine engineering facilities, such as wind power plants, which are equipped with one or more wind turbines, and the Offshore installations or even wave energy plants, as will be seen in the examples described below. Two types of power stations, one wind power station and the other wave power station, can be jointly installed on the platform 1 .

[0040] The platform 1 comprises a plurality of elongated buoyant tanks 2 arranged substantially parallel in a longitudinal direction corresponding to the main direction of surge of the swell when the platform 1 is located at sea (in figure 1 indicated by an arrow).

[0041] In the example, the number of these pontoons 2 is two, the pontoons have the shape of a parallelepiped with a square or (as indicated) rectangular cross-section, the height of the pontoons is preferably greate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com