Automatic welding equipment for parallel flow tube condenser connection tubes

A technology of automatic welding and parallel flow tubes, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of long time consumption, high production cost, and easy leakage of welding, so as to improve production efficiency and ensure Applicable and maintain the effect of beauty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

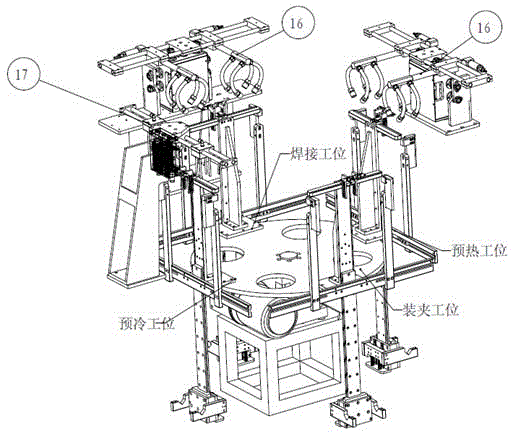

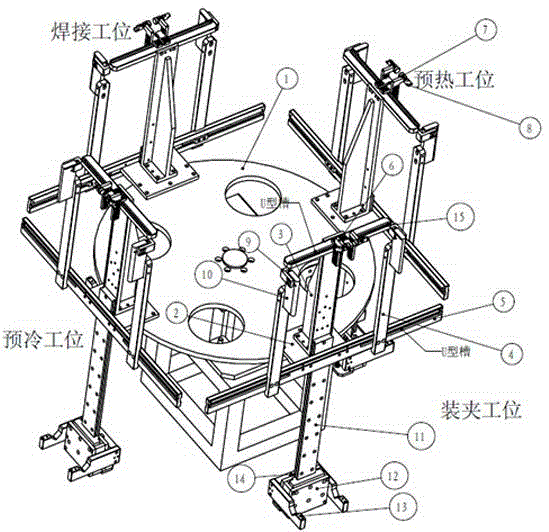

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] Such as figure 1 , 2 As shown, the automatic welding equipment based on the parallel flow tube condenser of the present invention includes a welding gun 16, a blowing cold pipe 17, a rotating platform 1, a condenser clamping device and a connecting pipe clamping device; the rotating platform 1 is fixed On the gear box, the entire disc is divided into four stations by an indexing device, which are clamping station, preheating station, welding station and precooling station, and each station is fixed with a sunken groove. The holes are used to fix the first connection plate 2 with screws, and the extension bracket 3 is fixed on the first connection plate 2, and the extension bracket 3 is used to connect and install the connecting pipe clamping device and the condenser clamping device.

[0014] The condenser clamping device includes a mobile bracket 4, a first sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com