Welding fixture for metal plates

A welding fixture and sheet metal technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as low clamping efficiency, improve clamping efficiency, improve processing efficiency, and facilitate processing and manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

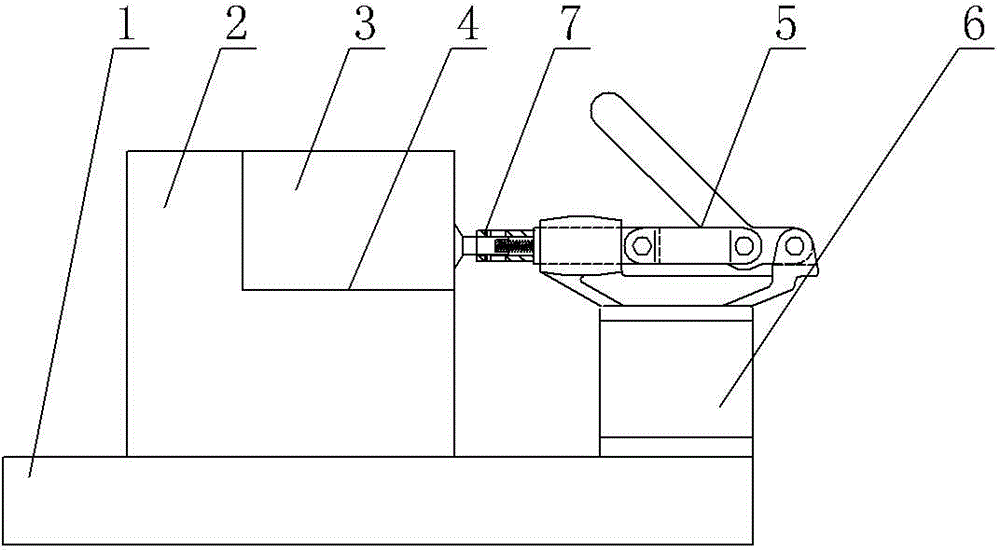

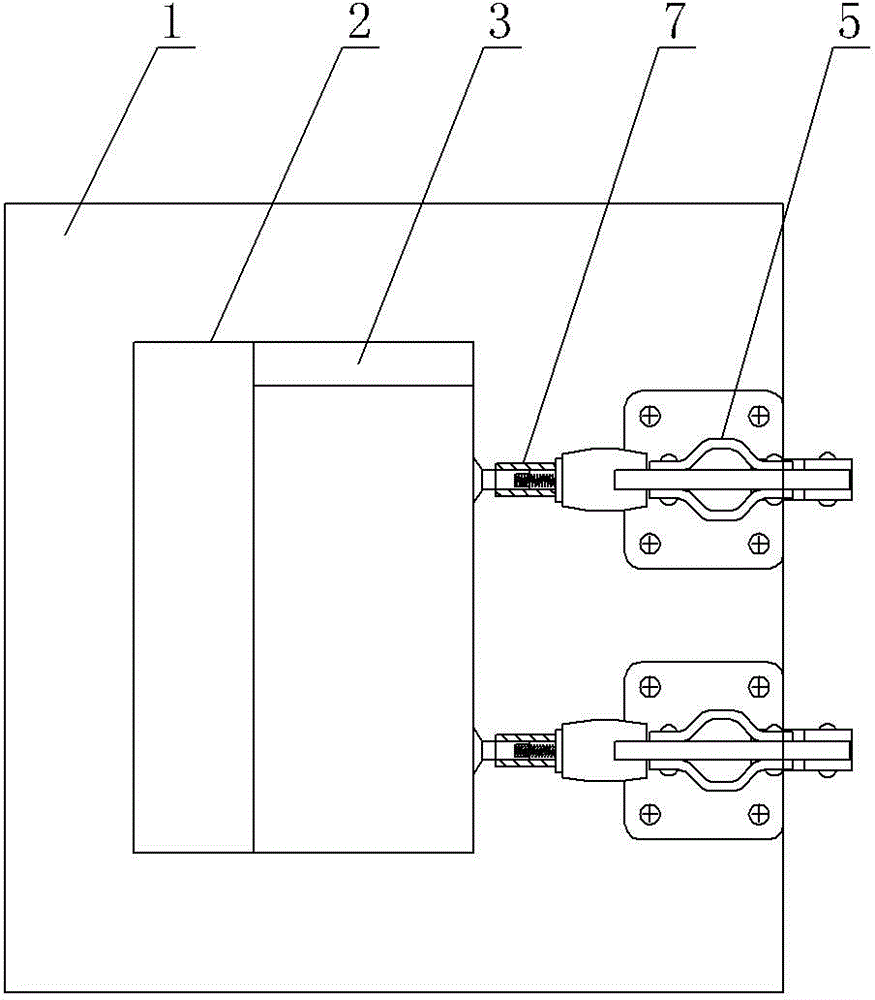

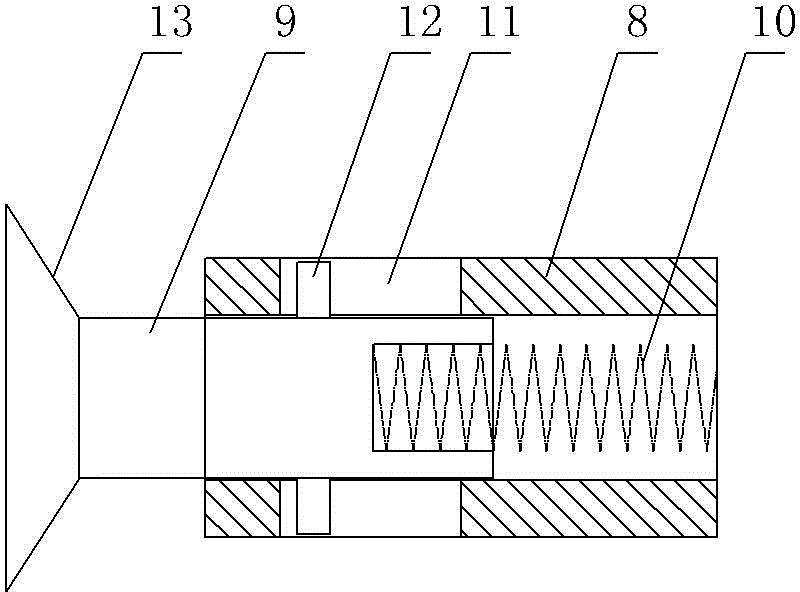

[0012] See Figure 1 to Figure 3 , a sheet metal welding fixture, which includes a bottom plate 1, a fixed block 2 is arranged on the bottom plate 1, and it is characterized in that: the upper part of the fixed block 2 is provided with a step surface 4, and the front end of the step surface 4 is vertically fixed with a limit plate, which is located on the step surface 4 Two push-pull quick clamps 5 are arranged on one side and the base plate 1, and the two quick clamps 5 are arranged side by side and fixed on the base plate 1 through the bracket 6. 7. The pressing piece 7 includes a sleeve 8, a pin 9 and a spring 10, the sleeve 8 is fixed on the front end of the push rod, the pin 9 is inserted into the sleeve 8, and the sleeve 8 is also equipped with a top-mounted push rod The spring 10 on the front end surface of the column pin 9 and the rear end surface of the column pin 9, the sleeve 8 has two groups of symmetrical waist-shaped perforations 11 along its axial directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com