A method for forming and manufacturing non-equal-thickness u-ribs

A manufacturing method and non-equal thickness technology, which is used in the forming and manufacturing of thick U-ribs and the production of steel structure building materials. It can solve the problems of small groove welding area, inconsistent bending dimensions, unclear stress release, etc. , The effect of facilitating penetration and eliminating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

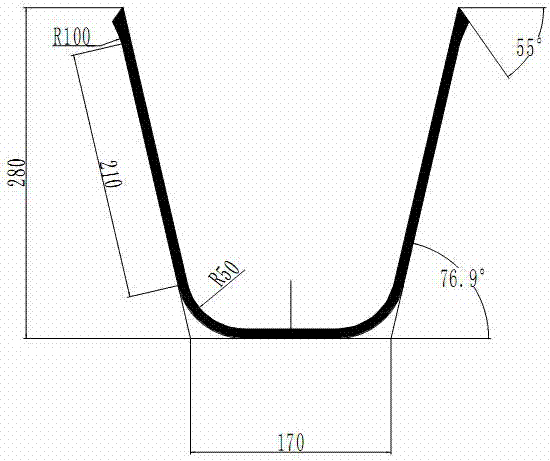

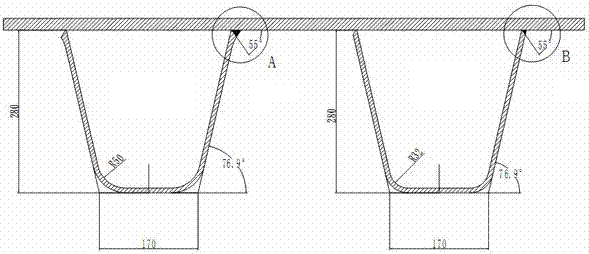

[0048] The embodiment of the method for forming and manufacturing non-uniform thickness U ribs of the present invention includes the steps of feeding, continuous hot forging deformation, rolling continuous cold bending deformation, and shaping. The continuous deformation of the raw steel plate of the U-shaped steel sheet pile from hot forging to cold bending is as follows: Figure 5 shown.

[0049]The steps of slitting the strip steel, uncoiling leveling, and shearing butt welding should be carried out before feeding. The cut hot-rolled coil is opened by the uncoiler on the cold roll forming unit, and the strip is leveled by a leveler. Shear butt welding is to cut the head of the strip and weld the head of the strip blank with a welding machine. The end is welded together with the tail of the strip steel that has entered the pass to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com