Wiring structure of tail end executor of industrial robot

An end-effector, industrial robot technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of reducing the service life of pipelines, prone to scratches, and excessive allowances, so as to improve service life and avoid excessive distortion. and the effect of excessive range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

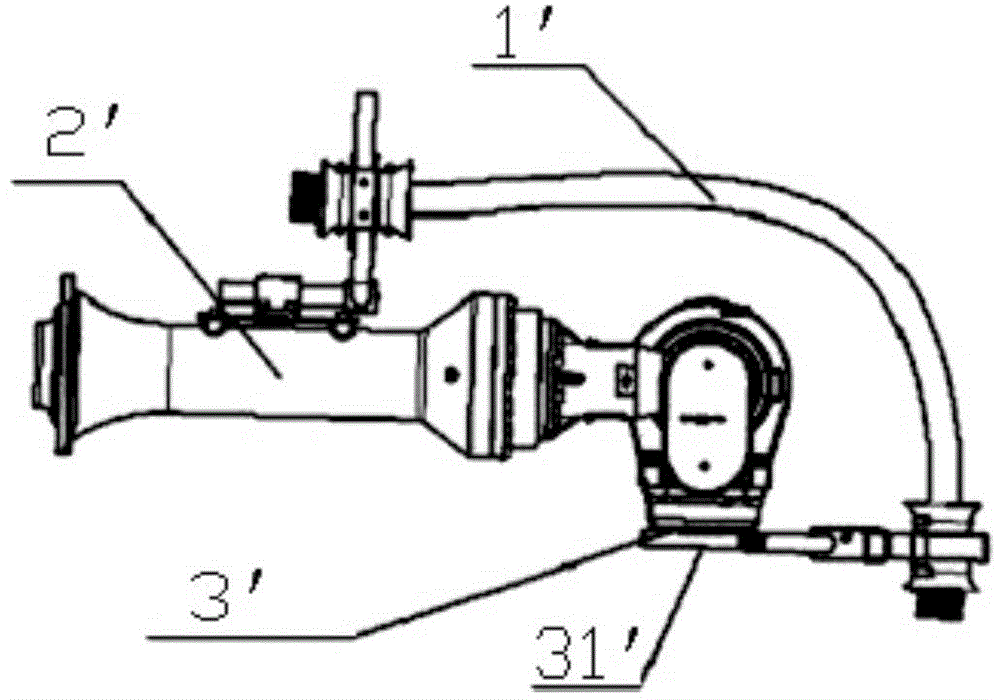

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

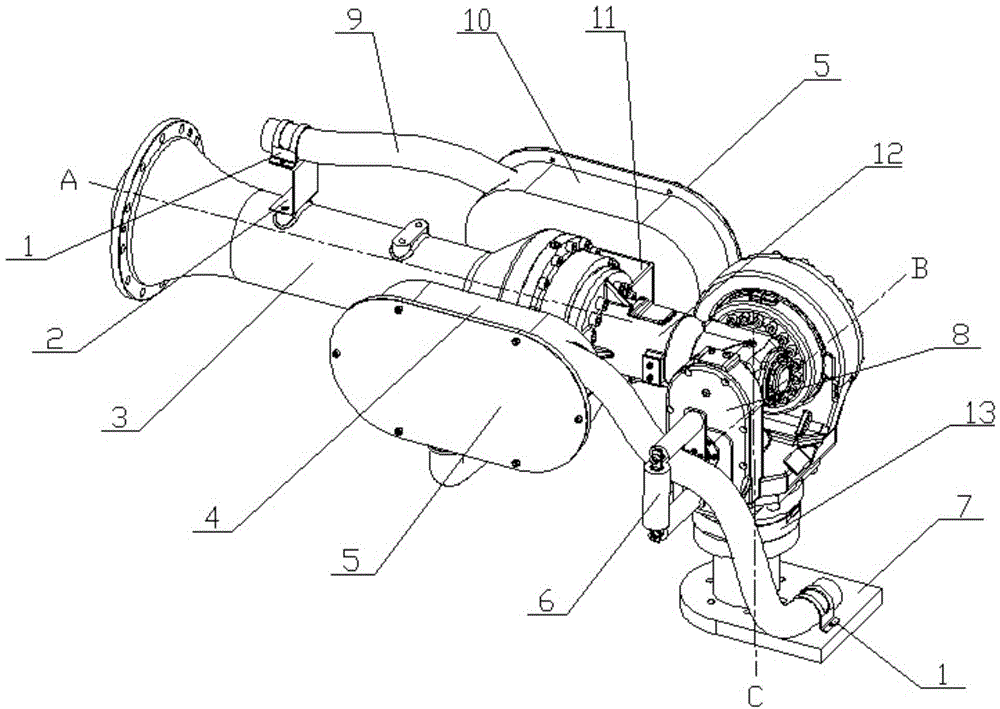

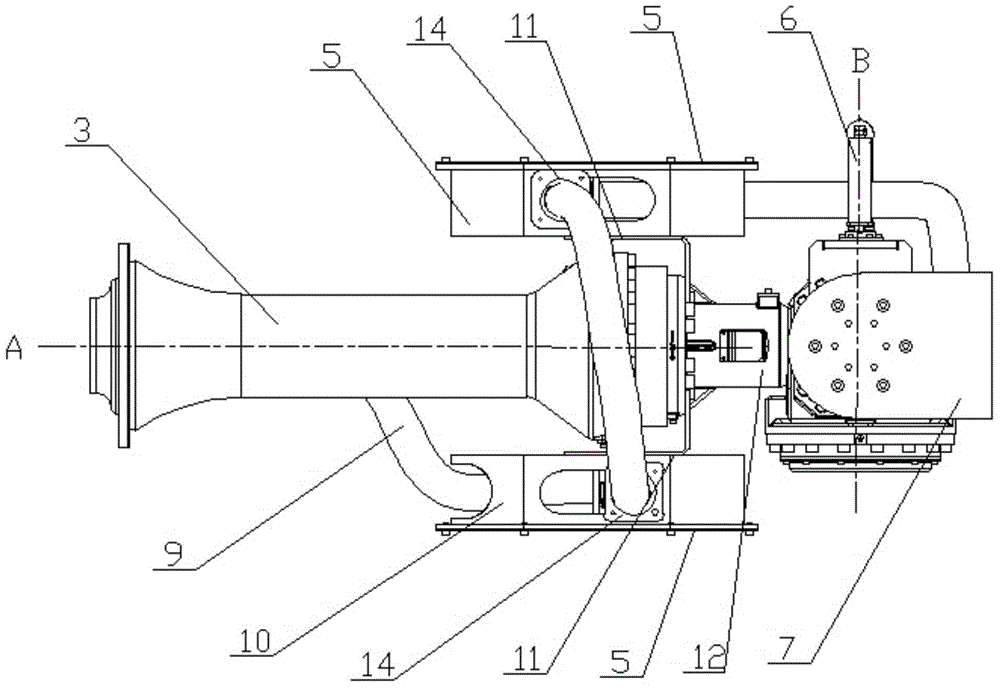

[0024] Hereinafter, the present invention will be described in detail by using figures and words.

[0025] Such as figure 2 As shown, the present invention discloses a wiring structure of an end effector of an industrial robot, which includes a large body tube 3, a box body is respectively provided on both sides of the large body tube 3, and a wrist is connected to the rear end of the large body tube 3, and the wrist includes A body wrist joint forearm 12 and a body end wrist 8 at the rear end thereof, a flange 13 is provided on the body end wrist 8, a base 7 is provided on the flange 13, and at least one pipeline 9 is connected to the base 7 and the body cylinder 3 .

[0026] Such as figure 2 and image 3 As shown, a first box body 4 and a second box body 10 are arranged symmetrically on both sides of the main body cylinder 3, and the first box body 4 and the second box body 10 are installed on the wrist joint forearm 12 of the body body through a mounting bracket 11. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com