Installation method of deep well pump suitable for ballast tank coating protection requirements

A technology of protection requirements and installation methods, applied in the field of shipbuilding, can solve the problems of destroying the ballast tank coating, affecting the coating integrity, failing to meet the protection specifications of the ballast tank coating, etc., and achieving the effect of avoiding welding and reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

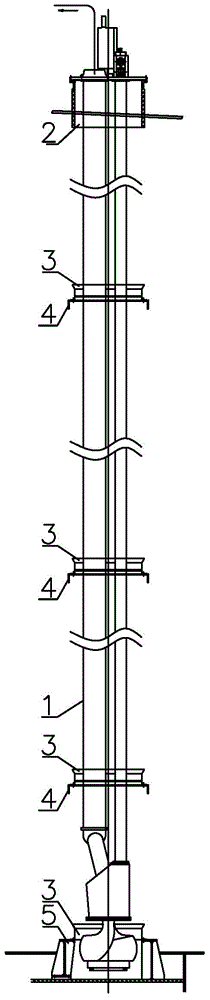

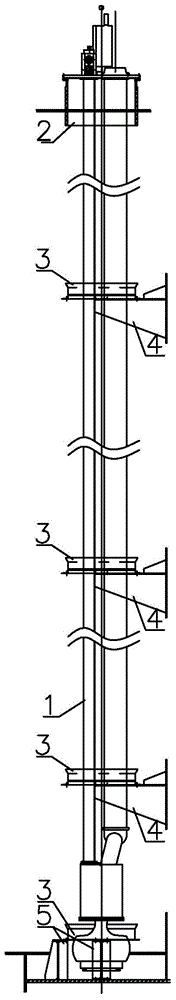

[0020] A deep well pump installation method suitable for ballast tank coating protection requirements of the present invention comprises the following steps:

[0021] S1, pre-install the bottom support 5 and the middle support 4 of the equipment during the sectioning of the hull (before closing and launching);

[0022] S2. After the hull is closed and launched, use the installation position of the bottom support as a reference to perform positioning and installation of the deck seat ring 2, and then use a bottom-up positioning method to sequentially position the middle seat ring 3. The middle seat ring is positioned and installed on the middle support and the bottom support;

[0023] S3. After step S2, the deep well pump 1 is installed.

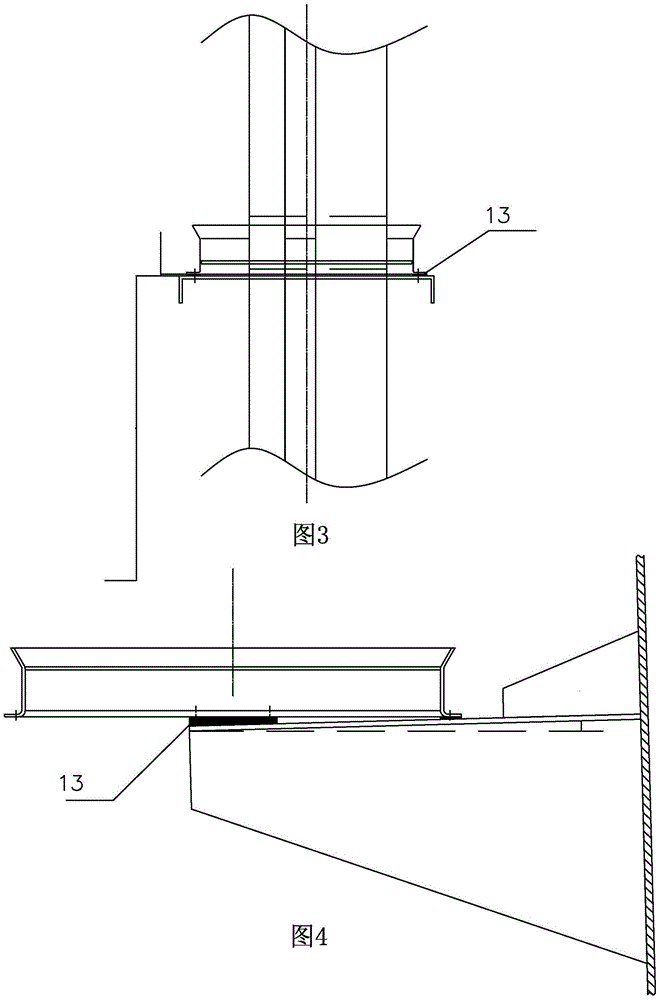

[0024] Wherein, in step S2, as shown in Figures 3 and 4, the positioning and installation of the intermediate race 3, the error existing in the height direction, uses the gasket between the intermediate support 4 and the intermediate race 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com