Method for preparing acetaldehyde oxime

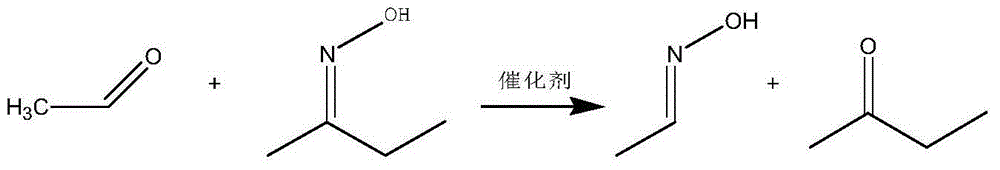

A technology for acetaldoxime and ketoxime, which is applied in the field of preparing acetaldoxime, can solve the problems of large amount of hydroxylamine salt, generation of by-products, unfriendly environment and the like, and achieves the effects of high selectivity, high conversion rate and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] a, the synthetic reaction of acetaldehyde oxime

[0024] Butanone oxime (Zhejiang Jinhua New Materials Co., Ltd.), acetaldehyde (Tianjin Kemiou, 40% aqueous solution) and hydrochloric acid (4% aqueous solution) were added to the reactor at a molar ratio of 1:2.0:0.1, Water was added to make the pH of the reaction system 4, and the reaction system was heated to a reaction temperature of 30° C., a reaction time of 8 hours, and a pressure of the reaction system at normal pressure.

[0025] b, the purification of acetaldehyde oxime

[0026] After the above reaction is completed, the product obtained by rectification and purification is acetaldehyde oxime. The detection and analysis results show that the conversion rate of acetaldehyde is 98%, and the selectivity of acetaldehyde oxime is 98%.

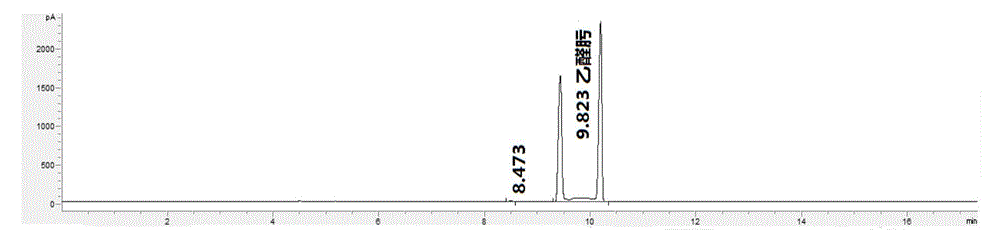

[0027] The gas chromatogram of the product is as follows figure 1 as shown in:

[0028] After gas chromatographic comparison with the standard product, the obtained product is acet...

Embodiment 2

[0030] a, the synthetic reaction of acetaldehyde oxime

[0031] Butanone oxime (Zhejiang Jinhua New Materials Co., Ltd.), acetaldehyde (Tianjin Kemiou, 40% aqueous solution) and sulfurous acid were added to the reactor at a molar ratio of 1:2.0:0.3, and water was added to make the reaction system The pH is 4.5, the above reaction system is heated, the reaction temperature is 50° C., the reaction time is 10 hours, and the pressure of the reaction system is normal pressure.

[0032] b, the purification of acetaldehyde oxime

[0033] After the above reaction, the reaction solution was rectified and purified to obtain the product acetaldehyde oxime. The detection and analysis showed that the conversion rate of acetaldehyde was 97.02%, and the selectivity was 98.52%.

[0034] It was confirmed that the product was acetaldehyde oxime through gas chromatography detection.

Embodiment 3

[0036] a, the synthetic reaction of acetaldehyde oxime

[0037] Butanone oxime (Zhejiang Jinhua New Materials Co., Ltd.), acetaldehyde (Tianjin Kemiou, 40% aqueous solution) and acetic acid were added to the reactor at a molar ratio of 1:2.0:0.6, and water was added to make the pH of the reaction system is 5, the above reaction system is heated, the reaction temperature is 50° C., the reaction time is 8 hours, and the pressure of the reaction system is normal pressure.

[0038] b, the purification of acetaldehyde oxime

[0039] After the above reaction is completed, the product obtained by rectification and purification is acetaldehyde oxime. The detection and analysis results show that the conversion rate of acetaldehyde is 99.21%, and the selectivity of acetaldehyde oxime is 99.12%.

[0040] It was confirmed that the product was acetaldehyde oxime through gas chromatography detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com