A rotating sample stage

A technology of sample stage and rotating shaft, applied in ion implantation plating, metal material coating process, coating and other directions, can solve the problems of narrow application range and inability to adjust the rotating sample stage, so as to improve the uniformity of the coating and the thickness of the coating. good sex, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] A rotary sample stage provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

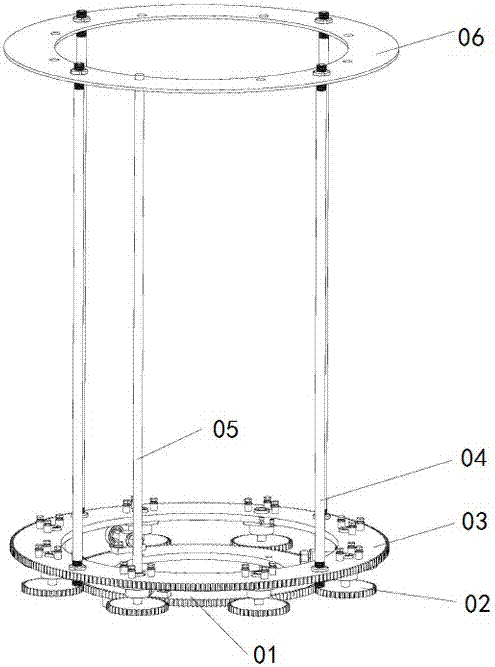

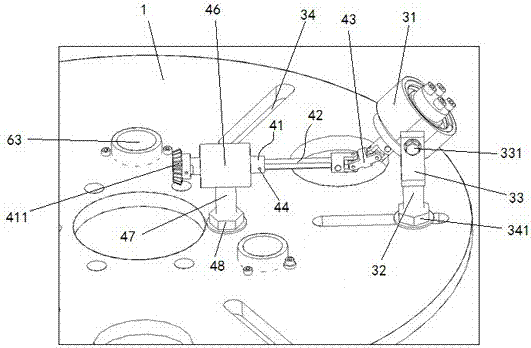

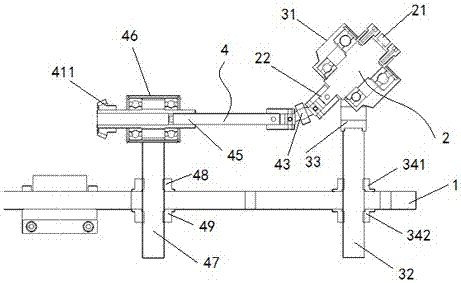

[0042] Such as Figure 2-6 Shown is the rotating sample stage disclosed by the present invention, which includes a revolution stage 1, which rotates around the revolution axis under the drive of the first driving device, and six sample stages 2 arranged at the same distance from the revolution axis respectively. 2 is supported by the first support member 3 fixed on the revolution table 1, and driven to rotate by the autorotation transmission member 4 located on the revolution table 1, and the autorotation transmission member 4 is driven by the second driving device; the sample stage 2 has a The bearing part 21 and the connection part 22 connected with the rotation transmission part 4, the rotation transmission part 4 can be axially expanded and contracted to push and pull the connection part 22, and then push and pull the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com