Construction method for removing integral ballast bed in subway operating line tunnel

A construction method, the technology of the integral ballast bed, applied in the direction of roads, tracks, laying tracks, etc., to achieve the effect of ensuring the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

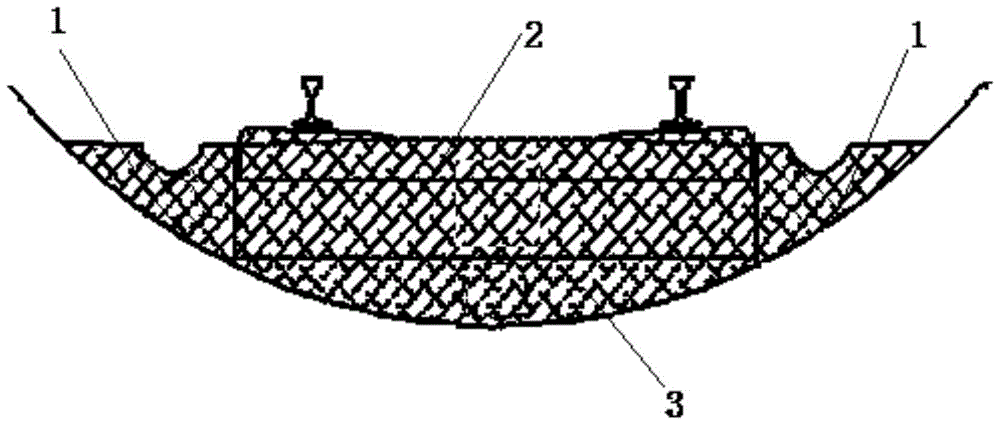

[0016] Refer to the attached picture, the construction method of removing the integral ballast bed in the tunnel of the railway operation line, and block the key points in the tunnel of the subway operation line. The specific construction steps are as follows:

[0017] 1) The first stage of concrete demolition: Use a high-frequency, low-noise wall saw to cut the concrete on both sides of the ditch along the longitudinal direction of the ballast bed on the outside of the sleeper head, divide it into small pieces with a hand-held saw, chisel it with an electric pick and a hydraulic pick, install The bag is transported outside, and the cutting depth is measured with a 4.3m long aluminum alloy ruler. According to the tunnel radius and tunnel convergence value, the vertical distance from the cutting surface to the ruler and the horizontal distance from the center of the tunnel are collected on site to determine the cutting depth;

[0018] 2) Remove the existing seamless line: Use an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com