A large double fine blanking machine linkage production line and its working method

A technology of double fine blanking machine and fine blanking machine, which is applied in the large-scale double fine blanking machine linkage production line and its work field, which can solve the problems of different processing efficiency, uncoordinated and complex operation of products, and achieve the effect of continuous operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

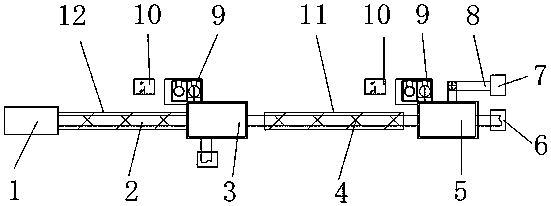

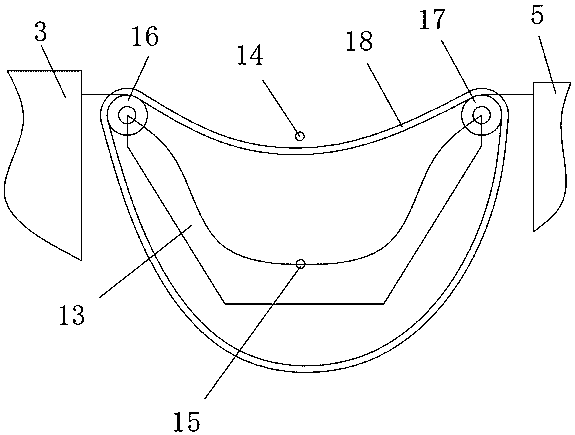

[0023] Embodiment: a kind of large double fine blanking machine linkage production line (see figure 1 figure 2 ), including two 650T level fine blanking machines, each fine blanking machine is equipped with an oil control circuit 9 and an electric control circuit 10, the first fine blanking machine 3 is used as the first sequence processing equipment, the second fine blanking machine Machine 5 is used as the final processing equipment. The main bodies of the two fine blanking machines are placed in a horizontal line. The first fine blanking machine is connected to the material leveling machine 1 through the material channel 12. The connection between the two fine blanking machines is used to transport semi-finished materials. A transitional bridge type material operation coordinating device 11 with a belt 4 . Both fine blanking machines are connected with a waste collection area 6 , and the second fine blanking machine is also connected with a finished product collection are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com