Drill stem inner wall cleaner facilitating fixing of friction part

A technology for friction parts and scale removers, which is applied in drilling tools, drilling equipment, earth-moving drilling, etc., can solve problems such as parts falling off, and achieve the effect of improving efficiency, increasing friction, and ensuring fixed stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

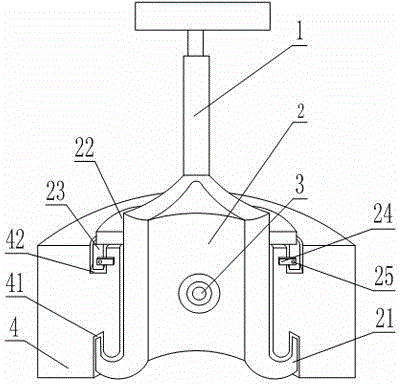

[0020] Such as figure 1 As shown, the descaling device for the inner wall of the drill pipe, which is convenient for fixing the friction parts, includes a hydraulic cylinder 1. The output end of the hydraulic cylinder 1 is connected with two symmetrically arranged fixed blocks 2. The fixed blocks 2 are bent inward to form an arc-shaped plate, and the two are fixed. The inner side of block 2 is connected by spring 3. The natural length of spring 3 is consistent with the inner diameter of the oil drill pipe. The lower end of the convex block 22 is provided with a fixed block 23, and the baffle plate 24 is detachably installed on both ends of the fixed block 23 through bolts 25. groove 41, and is set in the fixed groove 21 through the groove 41. The other end of the scouring pad 4 is provided with a card slot 42 that cooperates with the fixed block 23. The inner wall of the drill pipe is bonded, and the fixed block 2 is made of aluminum alloy.

[0021] The working principle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com