A self-pressurized remote-controlled condensate oil sealed recovery process method and device

A process method and technology of condensate oil, which are applied in the valve device of wellbore/well, earth-moving drilling, sealing/packing, etc., can solve the problem of good volatility of condensate oil, danger of burning and unblocking, large safety risk, etc. problems, to achieve the effect of high-efficiency separation of gas and liquid, solving the blockage of condensate, and avoiding casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

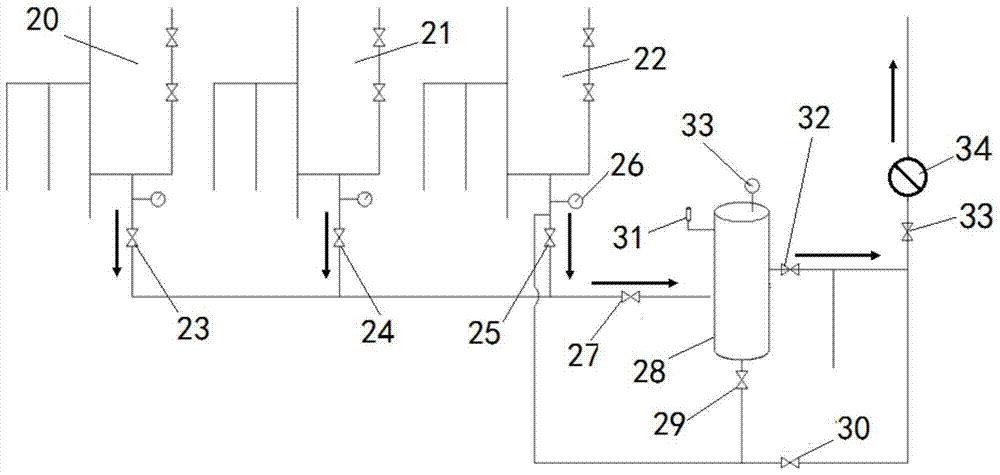

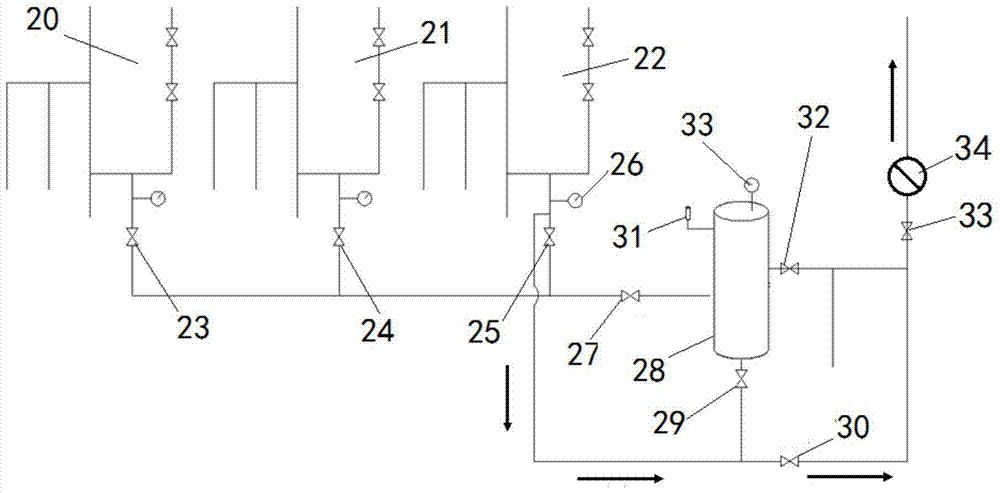

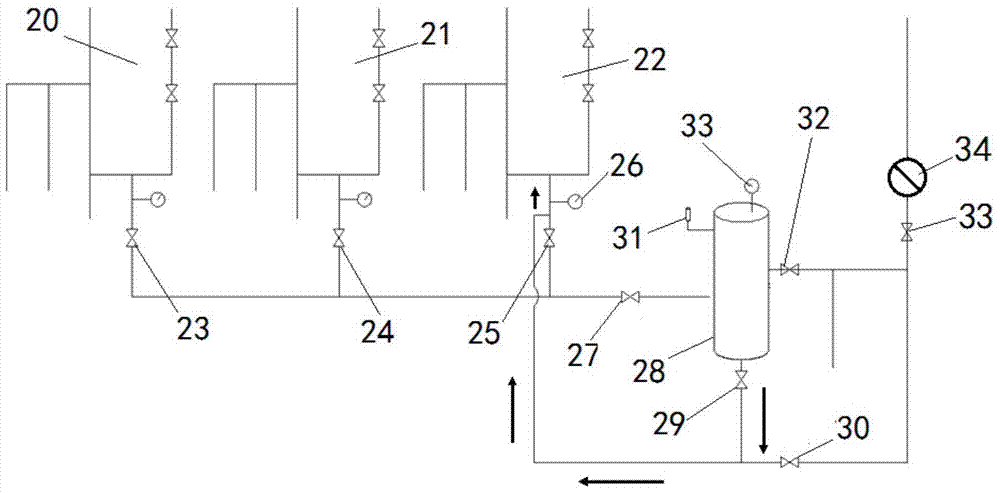

[0026] Embodiment 1: as figure 1 , figure 2 , image 3 and Figure 4 As shown, a self-pressurized remote control type condensate oil sealing recovery process device, the 1# oil well 20, the 2# oil well 21, and the 3# oil well 22 are respectively connected to the eighth gate 23, the seventh gate 24, and the sixth gate 25. The other ends of the eight gates 23, the seventh gate 24, and the sixth gate 25 are connected to the first gate 27, and the gas-liquid separator 28 is connected to the safety valve 31, the second gate 32, the third gate 29, the first gate 27 and Pressure gauge 33, the fifth gate 33 is connected to the flame arrester 34, the other end of the third gate 29 is connected to the other end of the sixth gate 25, the other end of the fourth gate 30, and one end of the fourth gate 30 is connected to the other end of the fifth gate 33 one end,

[0027] The 1# oil well 20 and the 2# oil well 21 are respectively connected to the oil well pressure gauge, and the 3# o...

Embodiment 2

[0029] Embodiment 2: as figure 1 , figure 2 , image 3 and Figure 4 As shown, a self-pressurized remote control type condensate oil closed recovery process method comprises the following steps;

[0030] Step 1. Associated gas normal venting process:

[0031] The associated gas produced by 1# oil well 20, 2# oil well 21, and 3# oil well 22 of oil wells merges into the first gate 27 after passing through the sixth gate 25, seventh gate 24, and eighth gate 23, and the other end of the first gate 27 Connected to the gas-liquid separator 28, the gas in the gas-liquid separator 28 goes up through the action of the coarse filter, multi-layer funnel and barrier ring, and the gas passes through the fine filter and is drawn out by the second gate 32 and the fifth gate 33 to the vent Torch, close the third gate 29 and the fourth gate 30 during the venting period; the liquid part generated in the gas-liquid separator 28 gathers to the lower layer to complete the entire separation pr...

Embodiment 3

[0037]Embodiment 3: A self-pressurized remote control type condensate oil sealing recovery process method, the gas-liquid separator can be installed on the concrete foundation 20m away from the well group, and the plane of the concrete foundation should be higher than the wellhead, so that the condensate oil can flow from When the liquid outlet flows out, it forms a slope with the wellhead, which is beneficial to self-pressure backflow. Place the direction of the gas-liquid separator according to the position of the associated gas interface, reserve the installation positions of the well gas pipeline, liquid pipeline, gas outlet pipeline, solenoid valve, gate and other components when placing it, and the direction of the gas outlet pipeline is installed and connected to the vent pipeline. The concrete platform is slightly larger than the length and width of the device, and should be higher than the surrounding ground by more than 200mm, so as to prevent rain from flooding the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com