Hard and brittle shale microfracture manufacturing method and plugging capability testing system

A production method and mud shale technology, which is applied in earthwork drilling, sealing/isolation, wellbore/well components, etc., can solve the problems of large difference and the inability to truly simulate the change process of hard and brittle mud shale and plugging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

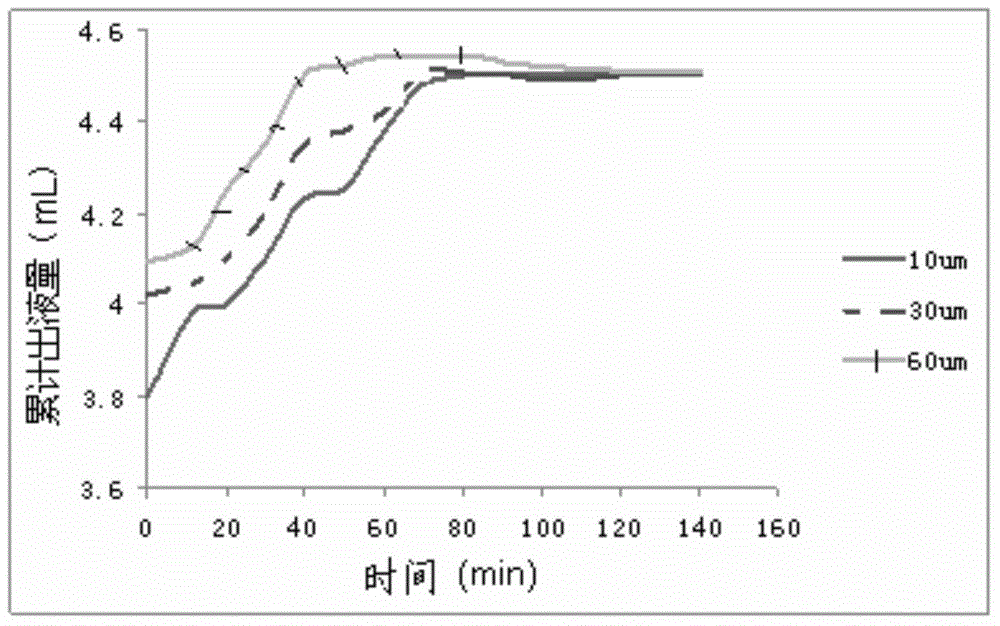

[0051] According to the operation steps, rock samples with crack widths of 10 μm, 30 μm and 60 μm were prepared, and three parts of water-based drilling fluid were prepared indoors, and 3% sulfonated asphalt was added to them. Use the test system of the present invention to carry out the plugging test experiments of 10 μm, 30 μm and 60 μm rock samples respectively according to the test steps, record the cumulative liquid output respectively, and make a curve graph, such as: image 3 shown.

[0052] from the curve image 3 It can be seen that the same drilling fluid formulation has different plugging effects on micro-fractures of different widths. The larger the fracture width, the greater the initial and cumulative fluid production. After 80 minutes, the graphs tend to be stable, indicating that the drilling fluid formulation has effectively plugged the fractures. After the experiment, the rubber sleeve was cut, and the invasion depth and accumulation of the mud cake in the ...

Embodiment 2

[0054] According to the operation steps, three rock samples with a crack width of 50 μm were prepared, and three water-based drilling fluids were prepared indoors, and 1%, 3%, and 5% of sulfonated asphalt were added to them respectively. Use the test system of the present invention to test the plugging ability of drilling fluids with different concentrations according to the test steps, record the accumulated liquid output, and make a graph, such as: Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com