Shaft coupling structure of calendaring machine

A calender, coupling technology, applied in the direction of coupling, rigid shaft coupling, mechanical equipment, etc., can solve the problem of reducing the coaxiality of the output shaft and the connecting shaft assembly, and inconvenient maintenance and replacement of the coupling or shaft , Reduce the service life of the coupling or shaft, etc., to achieve the effect of convenient and simple disassembly and maintenance, improve service life, and reduce wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

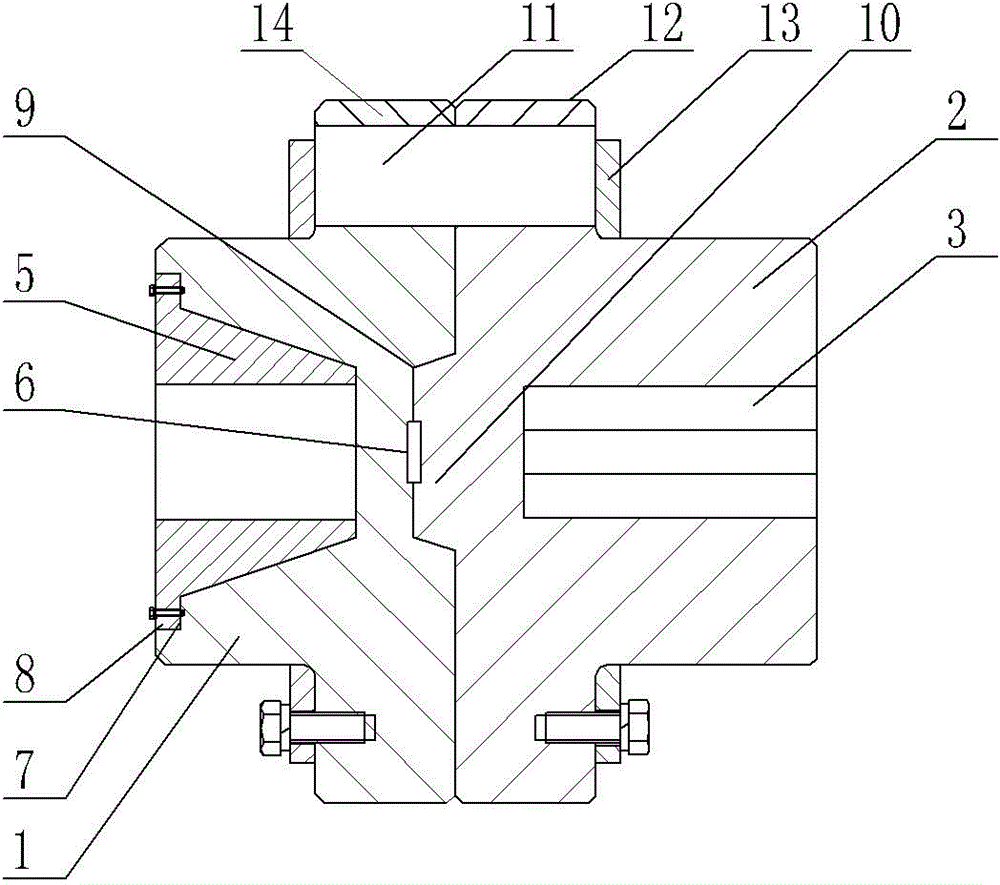

[0010] Such as figure 1 As shown, the coupling structure of the calender includes a connecting piece 1 and a connecting piece 2. The axial inner end surface of the connecting piece 2 is provided with a tapered bump 10, and the axial direction of the connecting piece 1 is The inner end surface is provided with a tapered groove 9 that cooperates with the tapered pin protrusion 10, and the end surface where the tapered protrusion 10 and the tapered groove 9 fit together is provided with a flat key 6, and the flanges of the first connector 1 and the second connector 2 The parts 14 and 12 are connected by nylon pins 11, the connecting piece 1 and the connecting piece 2 are respectively sleeved with a pressure plate 13, the inner end surface of the pressure plate 13 is pressed on the outer end surface of the column pin 11, and the pressure plate 13 and the flange part 12, 14 is fixed by bolts, the radius of the pressure plate 13 is smaller than the axial distance between the column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com