Gas pressure reducing valve

A pressure reducing valve and gas technology, applied in the field of gas pressure reducing valve, can solve the problems of inability to adjust, increase processing cost, inconvenient use, etc., and achieve the effects of reasonable installation structure, convenient air pressure adjustment, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

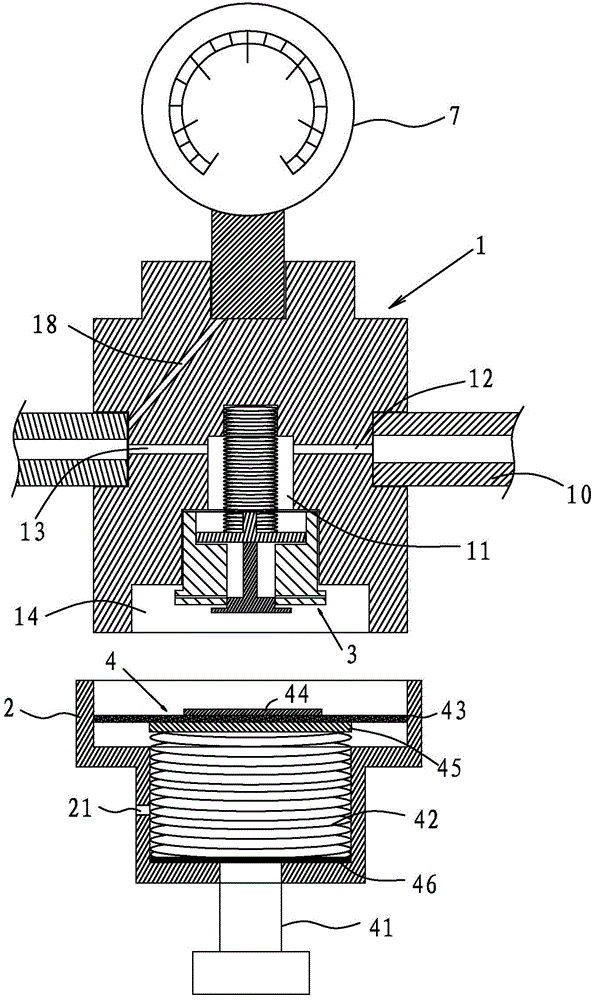

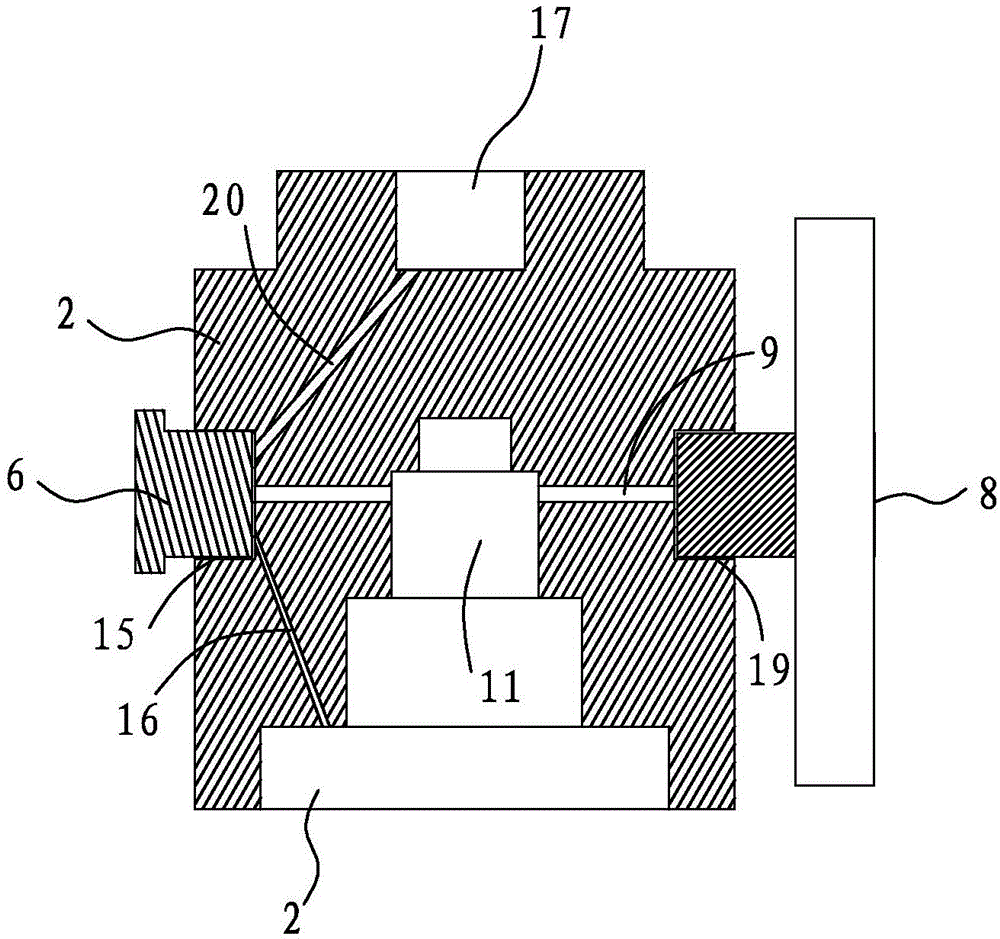

[0018] refer to figure 1 , figure 2 and image 3 Shown: gas pressure reducing valve, including valve seat 1, valve cover 2, decompression mechanism 3 and adjustment mechanism 4, valve seat 1 is matched with valve cover 2, valve seat 1 is provided with external thread, valve cover 2 inner wall is provided with Internal thread, the valve seat 1 and the valve cover 2 are connected through threads; the two are threaded to facilitate the adjustment of the space between the valve seat 1 and the valve cover 2.

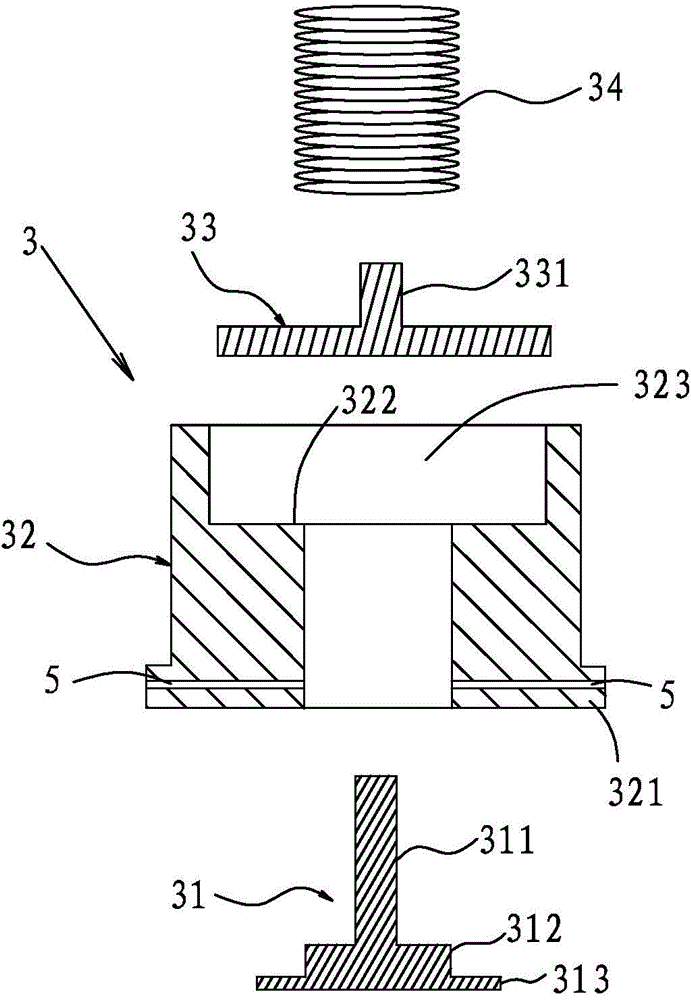

[0019] The decompression mechanism 3 includes a top block 31, a connecting piece 32, a movable piece 33 and an elastic piece 34, the elastic piece 34 is installed in the mounting groove 11, and the connecting piece 32 matches the mounting groove 11, wherein the elastic piece 34 can be a spring, The connecting piece 32 is a hollow bolt. Valve seat 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com