System and method for performing foreign matter inspection on upper surface of ultrathin glass substrate

A glass substrate and ultra-thin glass technology, which is applied in the direction of material analysis, measuring device, and instrument by optical means, can solve the problems of misjudging the size and quantity of particles on the upper surface, reducing the yield rate, and being expensive. Incident angle, reduce false positive rate, reduce the effect of image acquisition area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

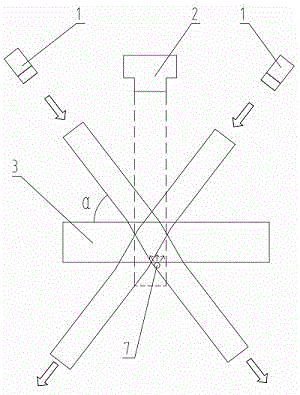

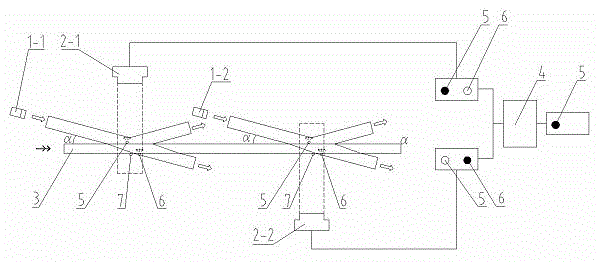

[0017] A system for inspecting foreign matter on the upper surface of an ultra-thin glass substrate. The structure includes a light source device 1 for illuminating the upper surface of a glass substrate 3, an imaging device, and an industrial computer 4 equipped with a management program. The key lies in: the light source device 1 The incident angle α of the emitted incident light on the upper surface of the glass substrate 3 is not greater than 45°, and the two supporting sets of imaging devices are symmetrically arranged on the upper and lower sides of the glass substrate 3, and are respectively attached to the glass substrate 3 by means of reflected light and refracted light. , the foreign matter on the lower surface, and transmit the digitized data to the industrial computer 4, and the industrial computer 4 uses the management program to compare the strength and weakness of the gray value of the two sets of imaging to form a system conclusion.

[0018] The light source dev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com