Load shedding method and system for safety automatic device based GOOSE information

A technology of safety automatic and knife switch, applied in information technology support systems, circuit devices, electrical components, etc., can solve the problems of the correctness and reliability of safety automatic devices, the difficulty of ensuring correctness, and the risk of major misoperations, etc., to achieve The effect of avoiding the risk of unintended load shedding and ensuring correctness and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

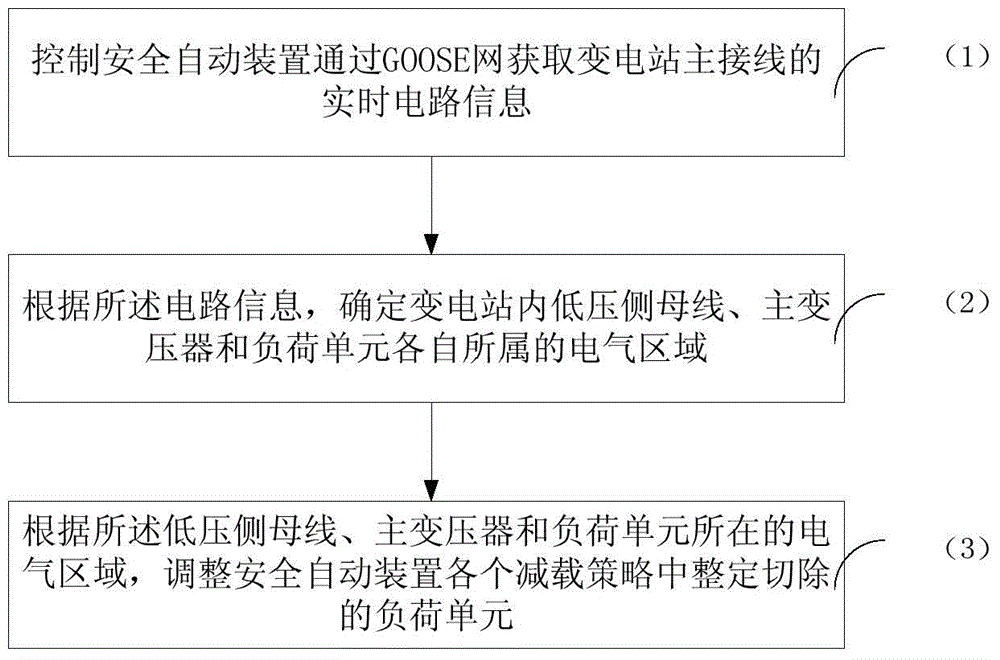

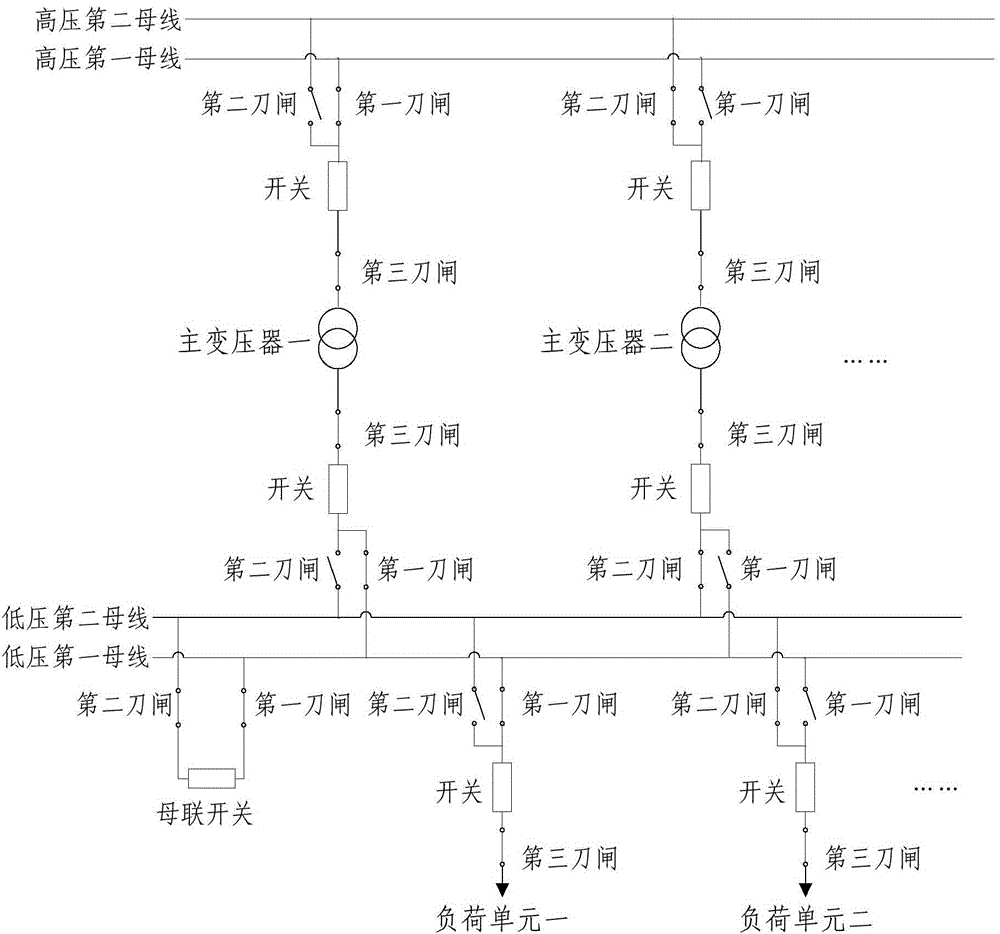

[0065] by figure 2 As an example, figure 2 It is a schematic diagram of the operation mode of the main wiring combined with the mother of the substation. An example of a load shedding method for a safety automatic device based on GOOSE information is as follows:

[0066] Step S201: Obtain real-time circuit information of the main wiring of the substation through the GOOSE network.

[0067] According to the above circuit information, the opening and closing information of the switch on the high-voltage side of the main transformer, the first knife switch, the second knife switch, and the third knife switch, and the switch on the low-voltage side of the main transformer, the first knife switch, and the second knife switch are extracted. , the opening and closing information of the third knife switch, the opening and closing information of the bus tie switch, the first knife switch and the second knife switch of the low-voltage side bus, and the switches of each load unit, th...

example 2

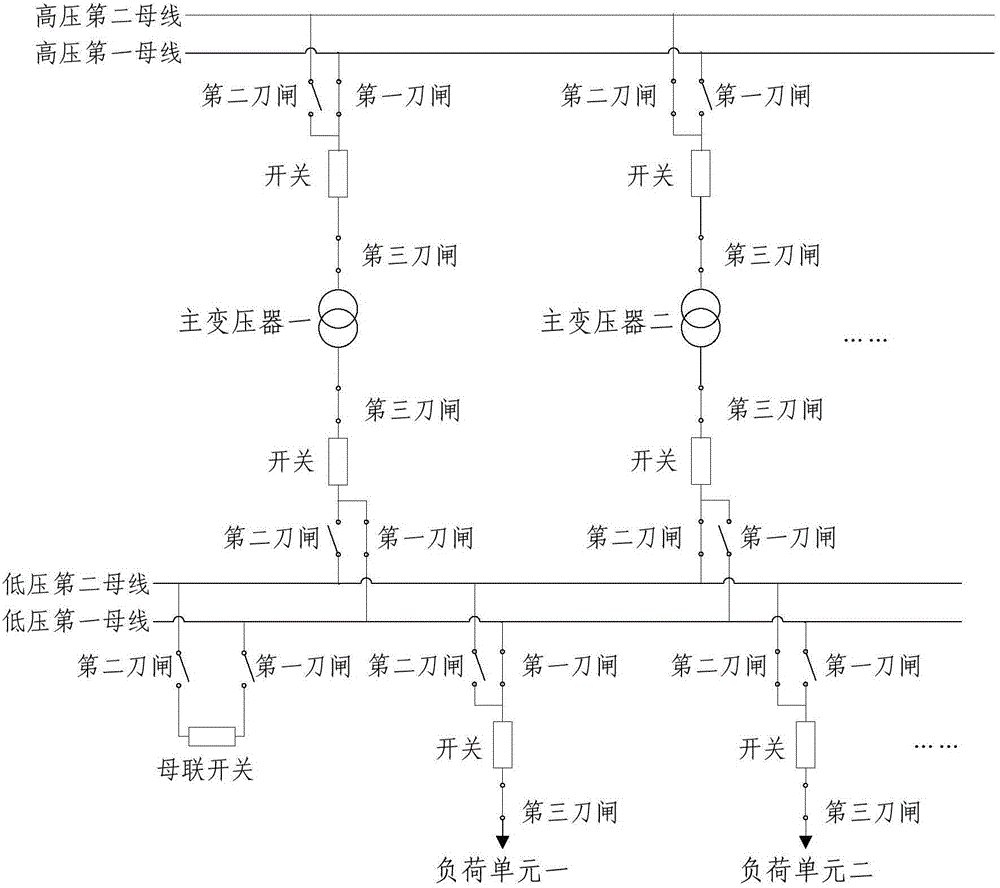

[0087] by image 3 As an example, image 3 It is a schematic diagram of the operation mode of the main wiring denominator of the substation. An example of a load shedding method for a safety automatic device based on GOOSE information is as follows:

[0088] Step S301: Obtain real-time circuit information of the main wiring of the substation through the GOOSE network.

[0089] According to the above circuit information, the opening and closing information of the switch on the high voltage side of the main transformer, the first knife switch, the second knife switch, and the third knife switch, the switching information of the switch on the low voltage side of the main transformer, the first knife switch, and the second knife switch can be extracted. switch, the opening and closing information of the third switch, the opening and closing information of the bus tie switch, the first switch and the second switch of the low-voltage side busbar, and the switches of each load unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com