Motor assembly for lifting seat and vehicle seat containing motor assembly

A technology of motor components and seats, applied in the direction of electric components, electrical components, movable seats, etc., can solve the problems of high cost and complex structure, and achieve the effect of low cost, simple structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

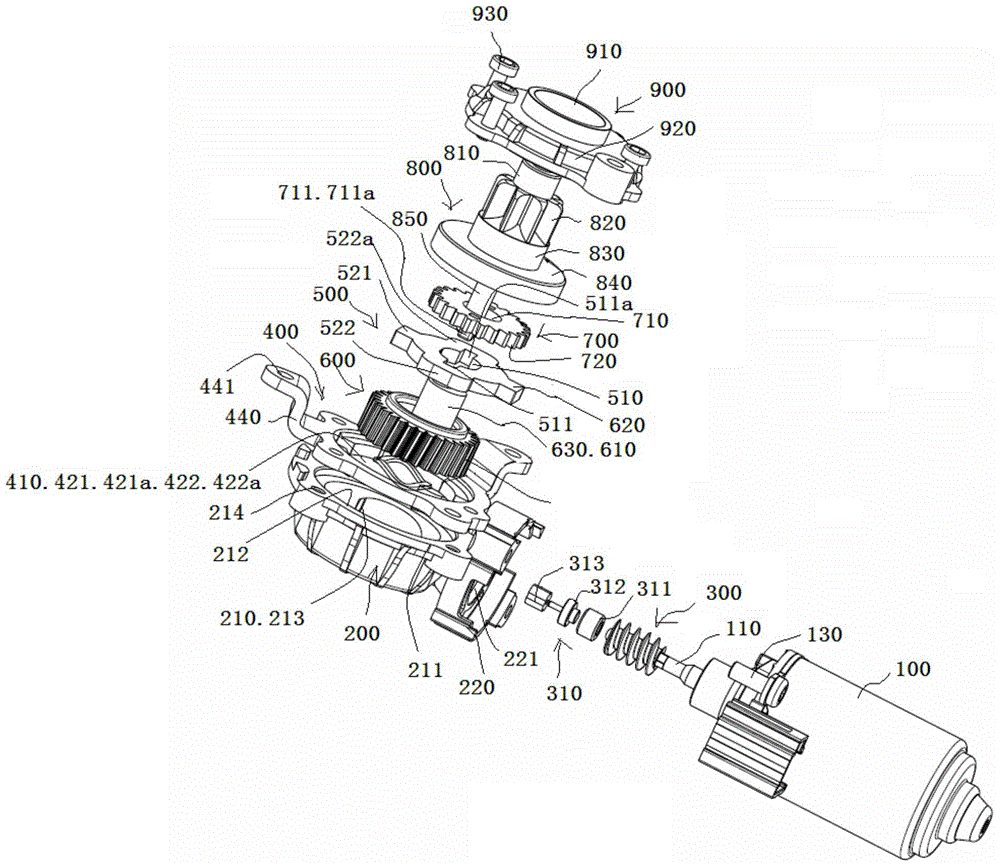

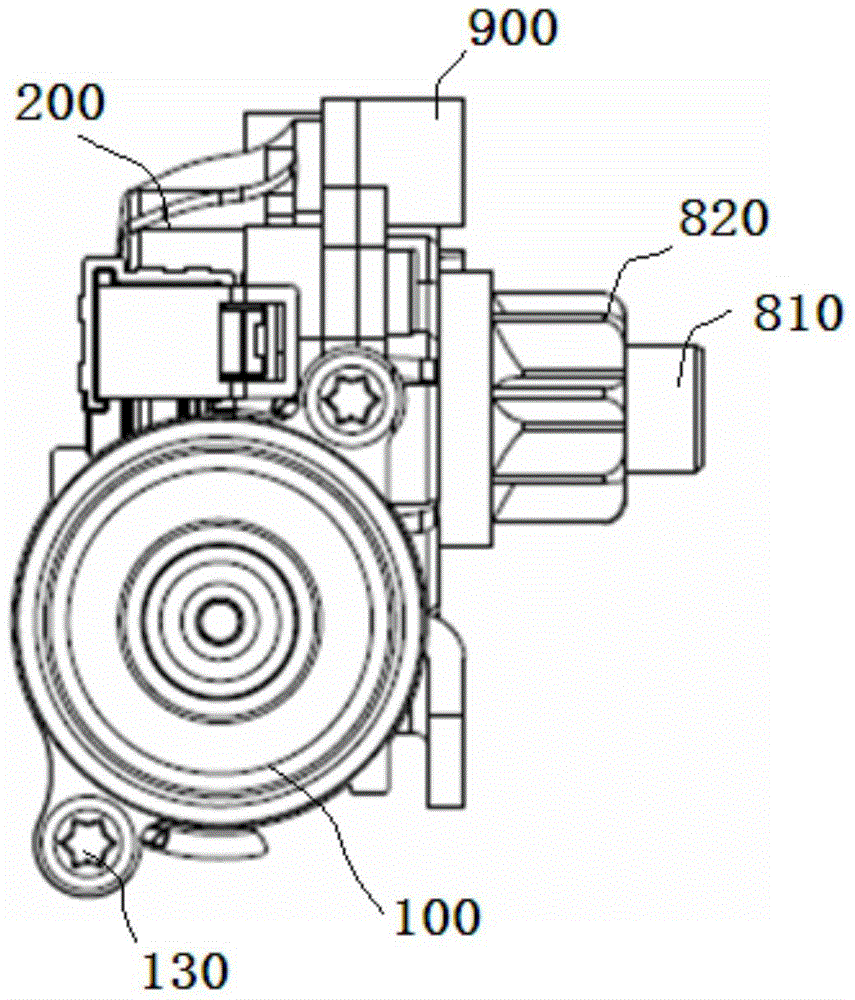

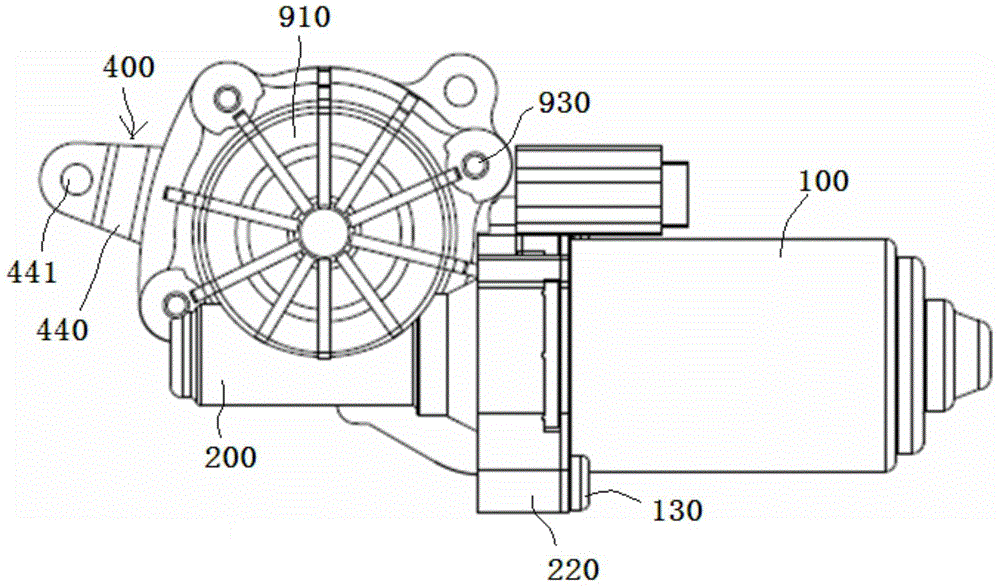

[0045] see Figure 1 to Figure 7 , the motor assembly of the raised seat shown in the figure includes a motor 100, a reduction box 200, a worm 300, a mounting bracket 400, a moving bracket 500, a double gear 600, a moving gear 700, an output gear assembly 800 and a reduction box cover 900.

[0046] The reduction box 200 is made of plastic and has an installation cavity 210 with an opening. The normal of the plane 211 where the opening is located is perpendicular to the axis of the output shaft 110 of the motor 100 . A motor mounting position 220 is provided on an outer surface of the reduction box body 200 , and an output shaft insertion hole 221 is disposed in the motor mounting position 220 , and the inner end of the output shaft insertion hole 221 communicates with the installation cavity 210 . The motor 100 is mounted on the motor mounting position 220 by using screws 130 , and the output shaft 110 of the motor 100 is inserted into the output shaft insertion hole 221 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com