Bracket structure for PVC (polyvinyl chloride) roof

A support structure and rectangular support technology, applied in the support structure of photovoltaic modules, photovoltaic power generation, photovoltaic modules and other directions, can solve the problems of many fixing problems of photovoltaic modules, and achieve the problem of bearing and long-term reliability, convenient installation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

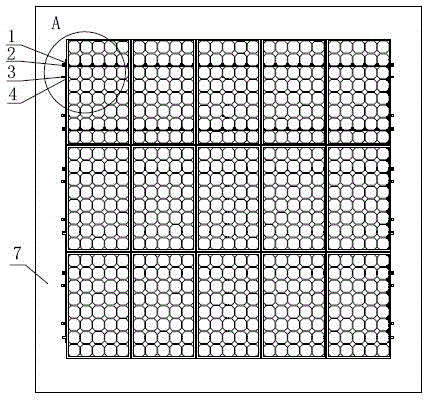

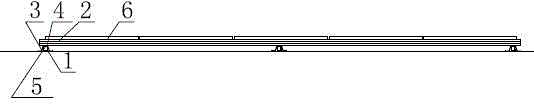

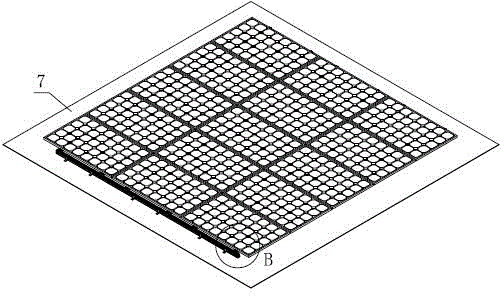

[0027] Such as figure 1 , figure 2 As shown, first, the bottom beam 1 and the purlin 2 are combined and arranged to form a 3*5 rectangular support, wherein there are three bottom beams 1, and each bottom beam 1 plays a supporting role. There are 6 purlins 2 , and each purlin 2 is used to fix the photovoltaic module 6 . In order to prevent the displacement of the bracket and reduce the deformation of the fixing material, a plurality of fixing parts 4 are installed on the bottom beam 1, and the longitudinal plates 4031 of the fixing parts 4 are embedded in the grooves (not shown in the figure) of the bottom beam 1, and the fixing strips 3 are fixed through The bending part of piece 4 is welded with roof 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com