Method for transplanting circuit board

A technology of circuit boards and sub-circuit boards, which is applied in the direction of assembling printed circuits with electrical components, can solve problems such as bending deformation, insufficient rigidity, damage, etc., and achieve the effect of strong structural rigidity and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the embodiments with reference to the accompanying drawings. The directional terms mentioned in the following embodiments, such as "upper", "lower", "front", "rear", "left", "right", etc., are only referring to the directions of the accompanying drawings. Accordingly, the directional terms used are illustrative, not limiting, of the invention. Also, in the following embodiments, the same or similar components will be given the same or similar symbols.

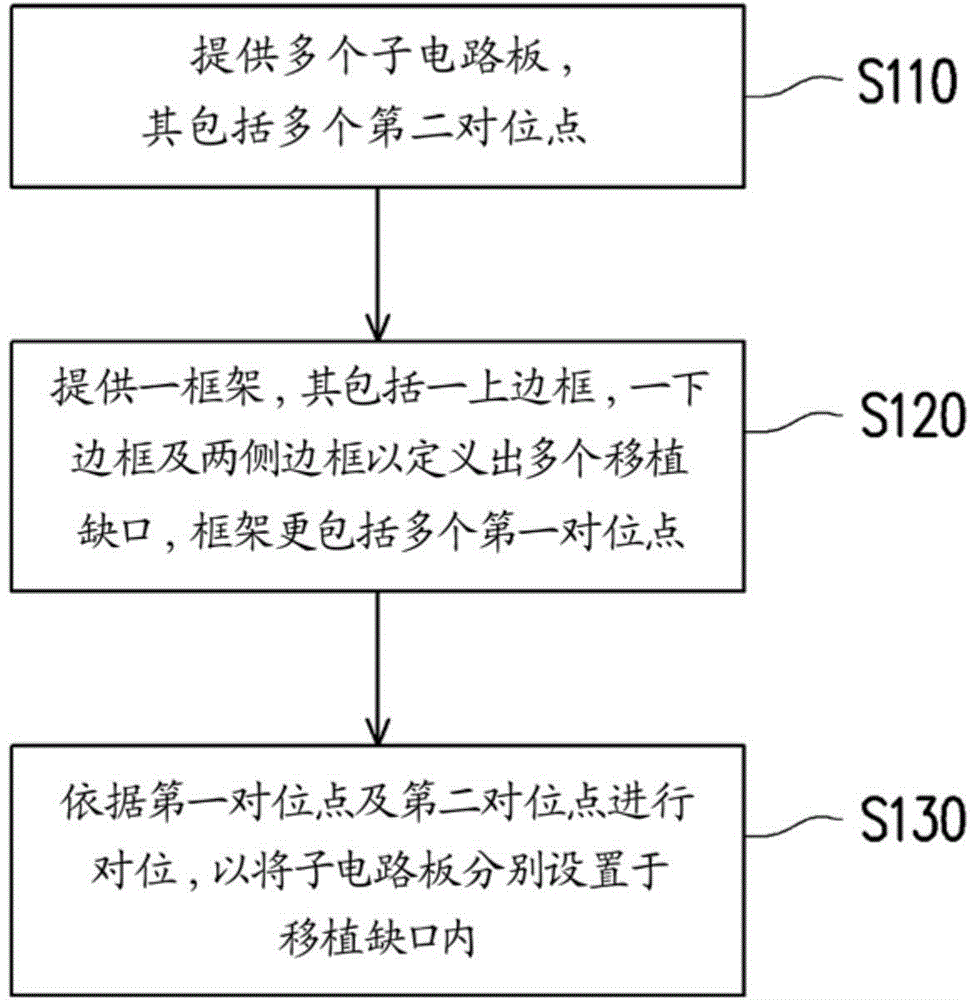

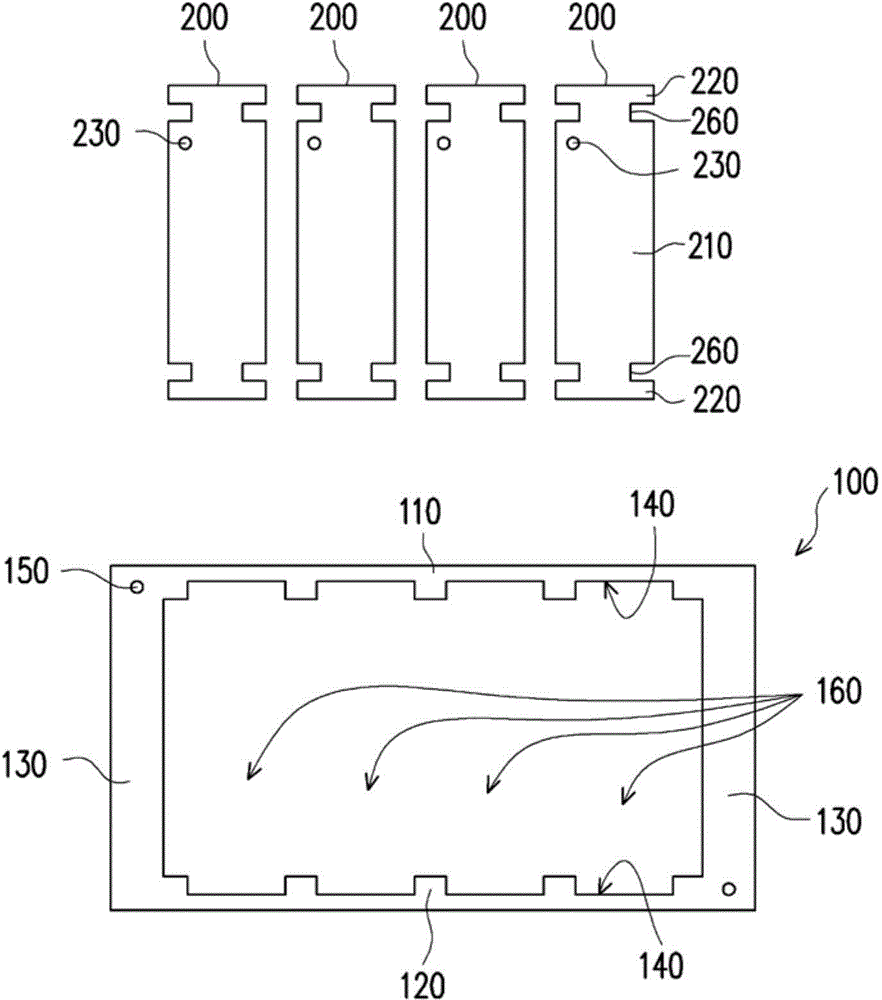

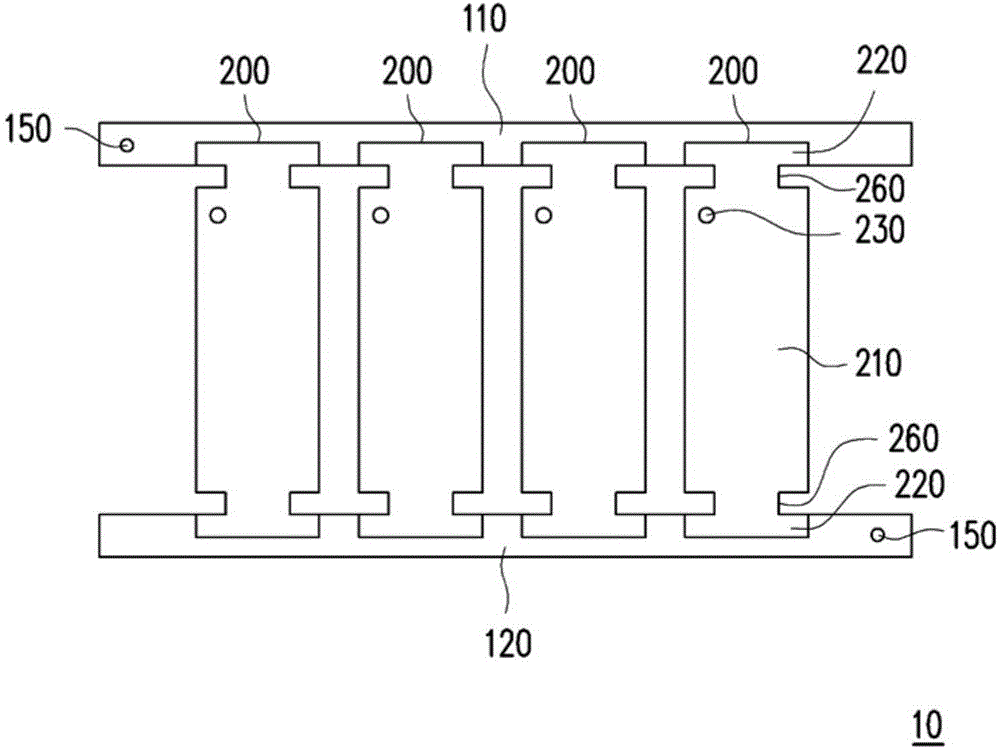

[0042] figure 1 It is a schematic flow diagram of a method for transplanting a circuit board according to an embodiment of the present invention. figure 2 It is a schematic diagram of a frame and a sub-circuit board according to an embodiment of the present invention. Please also refer to figure 1 as well as figure 2 The method for transplanting circuit b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com