Mite propagation inhibition sheet

A technology for suppressing sheets and mites, which is applied to devices for capturing or killing insects, lamination devices, and processing of layered products, etc. The effect of safety management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

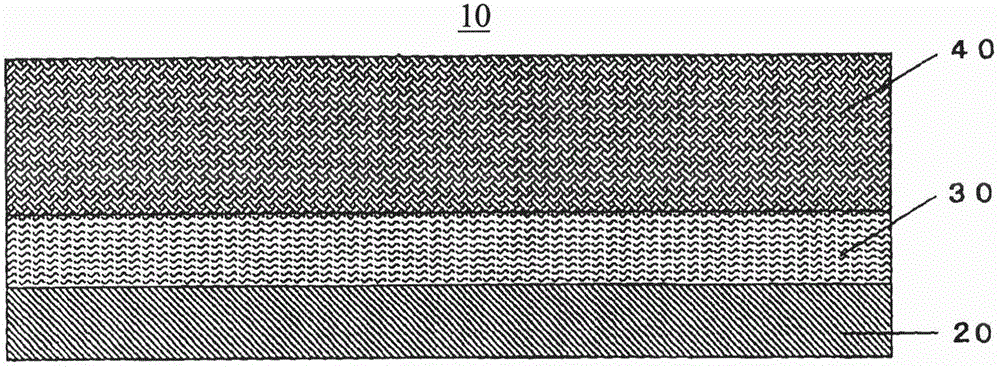

[0029] figure 2 Shown is the method for manufacturing the mite breeding suppressing sheet 10, comprising the steps of: providing an adhesive layer by coating an adhesive on one side of the sheet layer 20, and setting a non-woven fabric layer 40 on the adhesive layer 30, and then applying the above three The layers are lightly pressed, thereby combining the above three layers into a whole.

[0030] The hot-melt synthetic rubber adhesive is coated on one side of the polyester sheet with a thickness of 0.1 mm by a hot-melt synthetic rubber adhesive device, so that the thickness of the hot-melt synthetic rubber adhesive is 0.08. Then, a polyester-based nonwoven fabric having a thickness of 3 mm was attached to the adhesive layer using a pressure roller under low pressure, thereby integrating the above-mentioned three layers with each other to manufacture the mite reproduction suppressing sheet 10 . The adhesive did not adhere to the surface of the mite breeding suppressing sheet ...

Embodiment 2

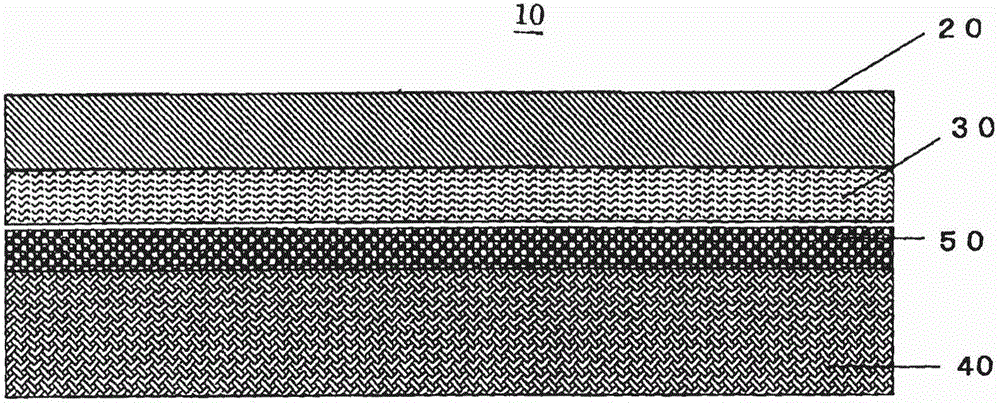

[0032] image 3 A method of manufacturing a mite breeding inhibiting sheet 10 is shown, comprising the steps of: coating an adhesive layer 30 on one side of a nonwoven fabric layer 40 to provide a layer 50, wherein the adhesive is penetrated into a part of the nonwoven fabric by hot melt spraying, The sheet layer 20 is then lightly pressed onto the adhesive-coated side surface of the non-woven fabric, thereby bonding the above four layers into a unitary body.

[0033] Adhesive layer 30 was coated on one side of a polyester sheet having a thickness of 4 mm to provide layer 50, wherein the adhesive was intruded into a portion of the nonwoven fabric by spraying a hot melt synthetic rubber based adhesive using hot melt spraying. A polyethylene-based layered paper having a thickness of 0.1 mm was then attached to the adhesive layer by pressing rolls under low pressure, thereby integrating the above-mentioned four layers into one body to manufacture the mite reproduction inhibiting ...

Embodiment 3

[0035] A method of manufacturing a mite breeding inhibiting sheet is shown, comprising the steps of: coating an adhesive layer 30 on one side of a nonwoven fabric layer 40 to provide a layer 50, wherein the adhesive is intruded into a part of the nonwoven fabric by spraying the adhesive, and then applying the sheet Layer 20 is lightly pressed onto the adhesive-coated side surface of the nonwoven, thereby bonding the above four layers into one.

[0036]Adhesive layer 30 was coated on one side of a polyester sheet having a thickness of 4 mm to provide layer 50, wherein the adhesive was impregnated into a portion of the nonwoven fabric by spraying a spray of synthetic rubber-based adhesive packaged in an aerosol can. Subsequently, the adhesive layer was covered with a polyethylene-based sheet having a thickness of 0.05 mm, and the sheet was lightly pressed by hand, thereby integrating the above four layers into a whole to manufacture the mite reproduction suppressing sheet 10 . T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com