Beaded photo frame

A technology of photo frames and frame beads, which is applied in the direction of picture frames, mirrors, household appliances, etc., can solve the problems of difficult repair, maintenance, difficult assembly and disassembly of the frame surface, and sawdust pollution, so as to change the consumption mode of home decoration, Easy maintenance and personalized styling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

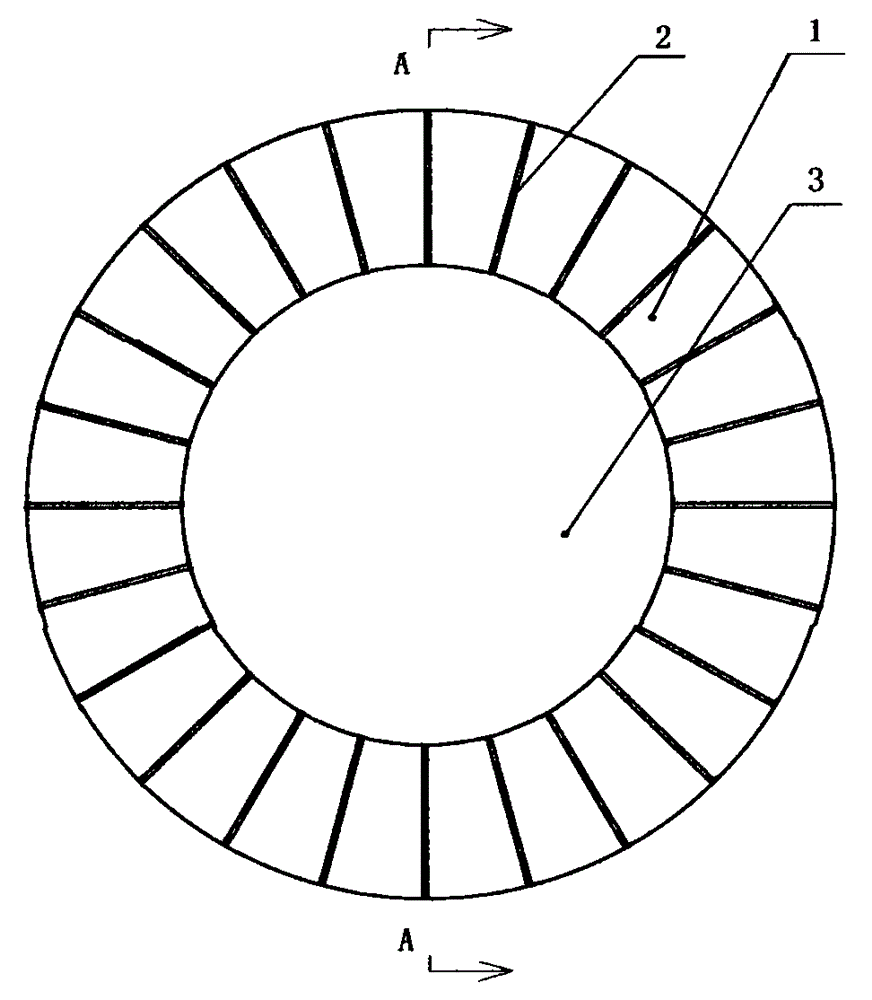

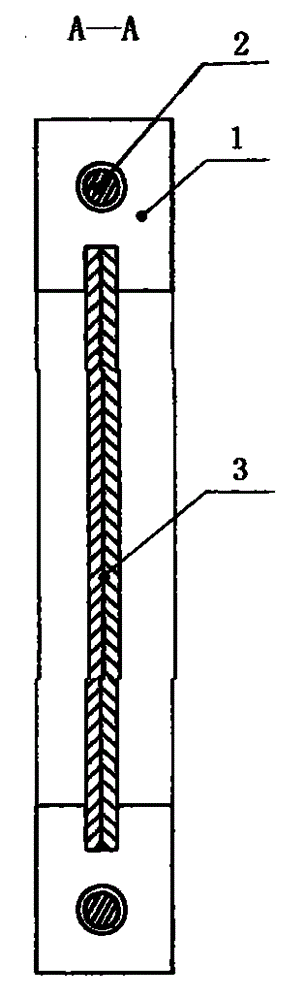

[0015] Embodiment 1: as figure 1 , figure 2 , image 3 As shown, the beaded photo frame includes 24 frame beads 1, the rope 2, and the inner core 3; the beaded photo frame includes 24 frame beads 1, the inside has a concave groove, and the middle has a through hole; the rope 2 is A long wire rope; the inner core 3 is a layer of transparent glass and a layer of iron sheet, and is circular.

[0016] During specific implementation, the rope 2 is inserted into the middle through hole of 24 frame beads 1 to form a frame bead string, and then the inner core 3 is placed in the concave groove of the frame bead string, and then the rope 2 Tie a knot and bind the inner core 3 to form a beaded photo frame that can display magnetic paper-cuts on one side and pictures on the other side. Can be hung in common ways.

Embodiment 2

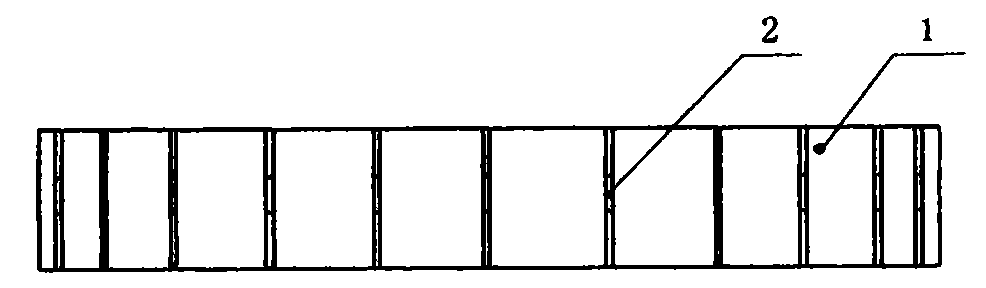

[0017] Embodiment 2: as Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the beaded photo frame includes 24 frame beads 1, 3 ropes 2, and the inner core 3; the beaded photo frame includes 24 frame beads 1, with a T-shaped card slot on the inside and a through hole in the middle; 3 The rope belt 2 is a long wire belt; the inner core 3 is a layer of transparent glass and a backboard, which is circular.

[0018] During specific implementation, the inner core 3 is placed in the T-shaped draw-in groove of the frame bead string of 24 frame beads 1 with 1 rope 2 preset, then tie a knot with the rope 2 that grows out, and then tie the two The ropes 2 are tied to the ropes 2 connecting the frame beads 1, and the inner core 3 is fixed firmly to form a beaded photo frame that can display pictures on one side. It can be hung in a common way, or a bracket can be installed behind the back panel to make an ornament.

Embodiment 3

[0019] Embodiment 3: As shown in Embodiment 1 and Embodiment 2 above, after the beaded photo frame is made, multiple beaded photo frames can be bound with ropes to form a screen, a multi-faceted three-dimensional box, a storage box, a desktop decoration, or a lamp. Because the technology is simple, ordinary people can do it, so no accompanying drawings will explain it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com