Preparation method and use of white-rot fungus mycelium biological adsorbent

A biosorbent and white-rot fungus technology, applied in chemical instruments and methods, biological water/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as complicated operation, hindering light projection, and difficult to degrade, and achieve adsorption reaction The effect of mild conditions, easy industrial application, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

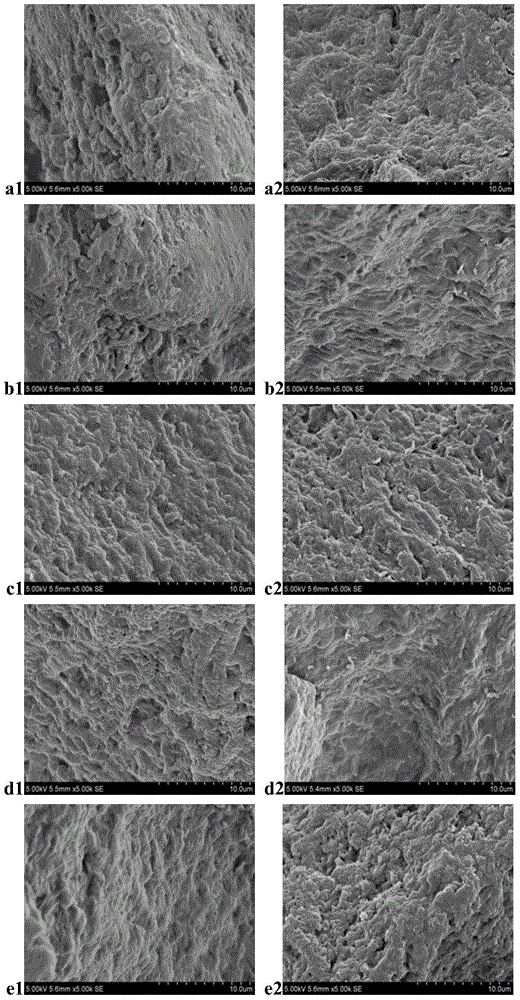

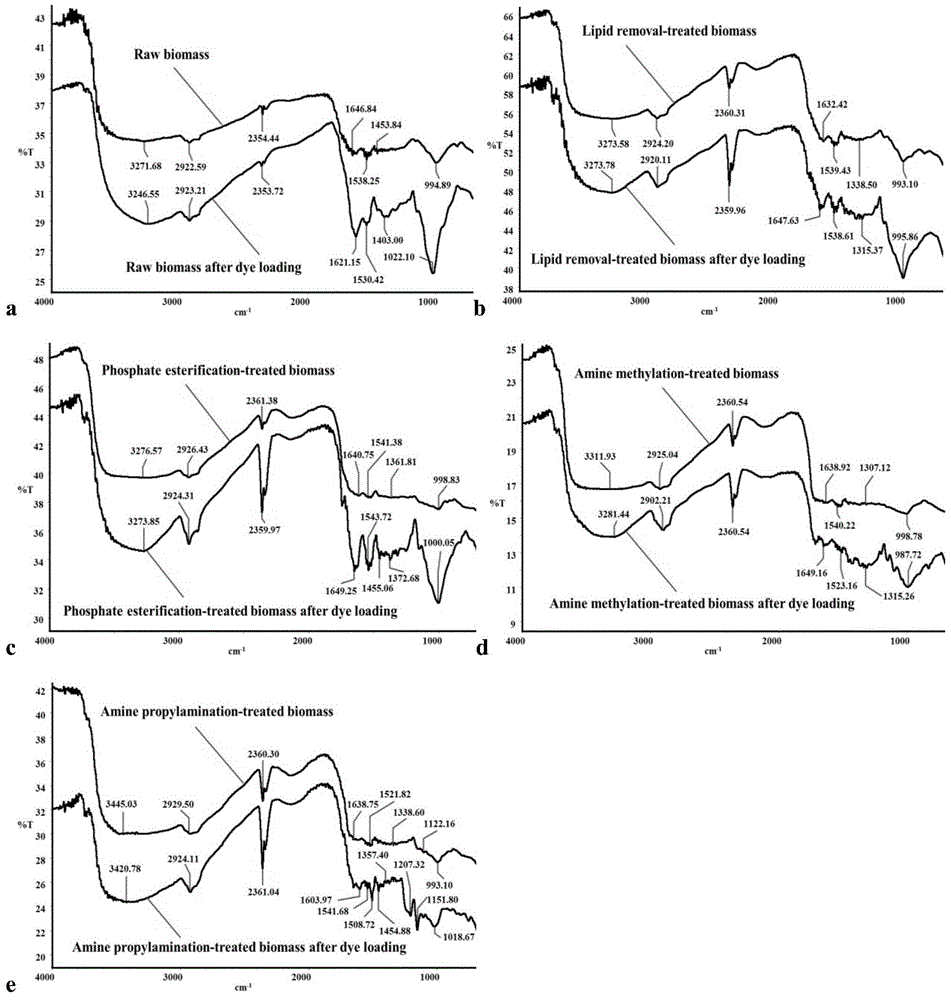

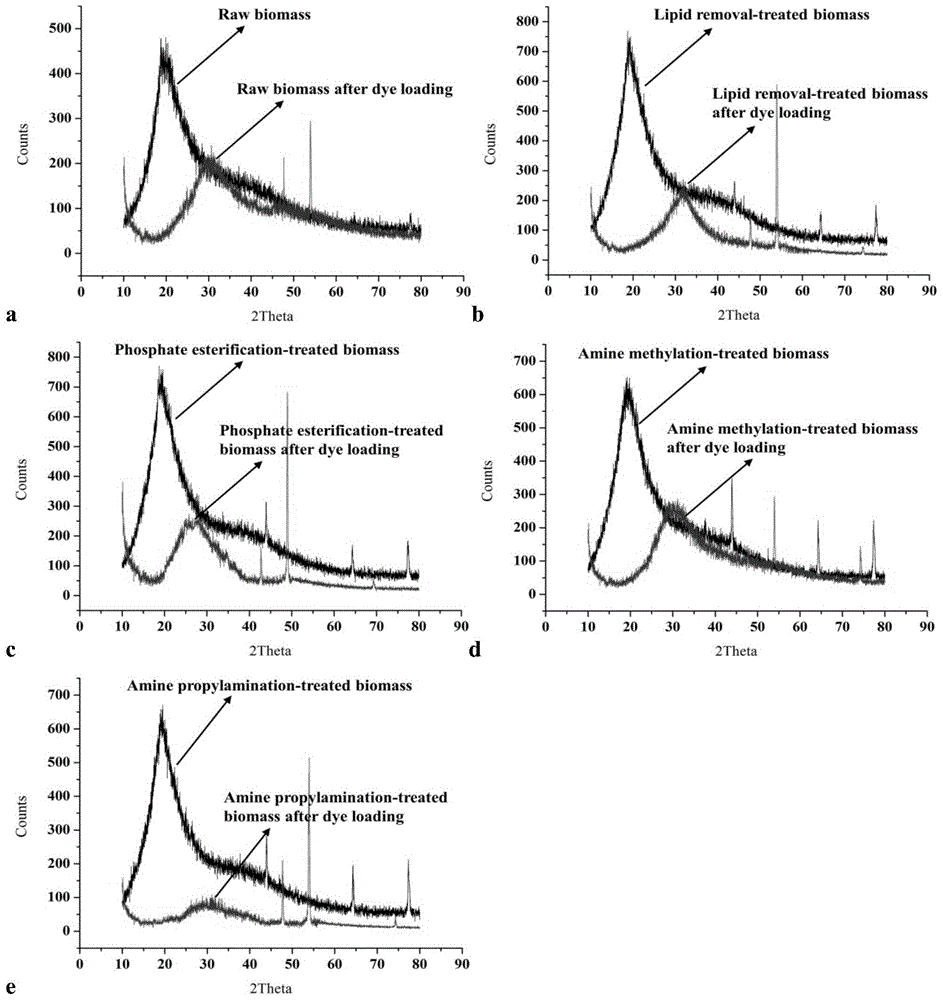

Method used

Image

Examples

Embodiment 1

[0059] Embodiment 1 prepares mycelia dry powder biosorbent

[0060] 1) Preparation of white rot fungus seed suspension

[0061] Inoculate the slightly acidic Poria perennialum refrigerated at 4°C on the plate medium, and carry out activation culture at 28±3°C for 7-8 days, and then inoculate an appropriate amount of the activated microacidic Poriaphyllum perennialis on the In 100mL of liquid medium, cultured on a shaker at a speed of 150rpm for 6 days at 28°C, then stirred with a homogenizer at a speed of 5000rpm for 30s to obtain a seed suspension;

[0062] Wherein, the preparation method of the liquid medium is as follows: glucose 20.0g, yeast extract powder 5.0g, KH 2 PO 4 1.0g, MgSO 4 ·7H 2 O0.5g, ZnSO 4 ·7H 2 O50mg dissolved in deionized water, adjusted to a total volume of 1000mL, pH natural, 1×10 5 Pa autoclave for 30 minutes, add 10 mg of vitamin B1 that has been filtered and sterilized when finger temperature is touchable, mix well and set aside.

[0063] 2) P...

Embodiment 2

[0067] Embodiment 2 prepares mycelia dry powder biosorbent

[0068] In addition to the preparation method of the liquid medium described in step 1), glucose 22.0g, yeast extract powder 4.5g, KH 2 PO 4 1.1g, MgSO 4 ·7H 2 O0.45g, ZnSO 4 ·7H 2 O55mg dissolved in deionized water, adjust the total volume to 1000mL, pH natural, 1×10 5 Pa autoclave for 30 minutes, add 9 mg of vitamin B1 that has been filtered and sterilized when it is warm to the touch, and mix well for later use; in step 2), inoculate 2.2 mL of seed suspension into 100 mL of liquid medium at a temperature of 31 °C Under these conditions, culture was carried out on a shaker at a rotation speed of 160 rpm for 6 days; except that the drying temperature in step 3) was 80° C., the rest was the same as in Example 1.

Embodiment 3

[0069] Embodiment 3 prepares mycelia dry powder biosorbent

[0070] In addition to the preparation method of the liquid medium described in step 1), glucose 18.0g, yeast extract powder 5.5g, KH 2 PO 4 0.9g, MgSO 4 ·7H 2 O0.55g, ZnSO 4 ·7H 2 O45mg dissolved in deionized water, adjust the total volume to 1000mL, pH natural, 1×10 5 Pa autoclave for 30 minutes, add 11 mg of vitamin B1 that has been filtered and sterilized when it is warm to the touch, and mix well for later use; in step 2), inoculate 1.8 mL of seed suspension into 100 mL of liquid medium, at a temperature of 25 °C Under these conditions, culture was carried out on a shaker at a rotation speed of 140 rpm for 8 days; except that the drying temperature in step 3) was 70° C., the rest was the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com