Electric soldering iron with timing device

A technology of electric soldering iron and soldering iron, which is applied in the direction of soldering iron, metal processing equipment, manufacturing tools, etc., can solve the problems of difficulty in timing shutdown, lack of use time detection device of electric soldering iron, and reduced safety, so as to improve safety hazards and be practical Good sex and effective control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

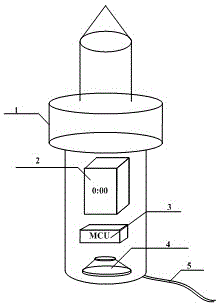

[0016] An electric soldering iron with a time telling device comprises a soldering iron main body, a clock display, a microcontroller, a loudspeaker, and wires. The clock display is embedded in the upper part of the handle part of the soldering iron body, the controller is installed in the middle of the handle part of the soldering iron body, and the lower part of the clock display; the speaker is installed in the lower part of the soldering iron body; the wire is connected to the bottom of the soldering iron body.

[0017] Because of the timing controlled by the microcontroller, the present invention can accurately calculate the time spent from starting up to "now", so that the heating of the soldering iron can be better estimated according to the heating model of the soldering iron, and the soldering iron maintains a high temperature for too long Automatically cut off the power supply at the time, which can better make up for the safety hazard of the soldering iron.

Embodiment 2

[0019] An electric soldering iron with a time telling device, the heating core adopts an iron core; the clock display adopts an LCD display. More innovative and practical.

[0020] The adoption of the iron core can enhance the plasticity of the overall manufacturing, making the cost of the present invention lower; at the same time, the LCD display screen also clearly shows the auxiliary reminder of the time last night. Comprehensively play the role of reducing the safety hazard of soldering iron.

[0021] In actual use, the electric wire is inserted into the mains plug, then the soldering iron starts to work, and the microprocessor also starts to calculate the working time of the soldering iron. When the working time is too long, the microprocessor controls the loudspeaker to give a loud reminder to remind the user to turn off the power or reduce the temperature of the soldering iron, thereby protecting the soldering iron and reducing the possibility of safety accidents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com