A steel fiber composite artistic guard net material structure and a manufacturing process

A technology of material structure and manufacturing process, which is applied in the processing field of material structure and manufacturing process of steel fiber composite art protective net, can solve the problems of monotonous and tedious horizontal and vertical cross shapes, and cannot meet aesthetic requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Use glass fiber reinforced plastic raw materials and steel fiber wire;

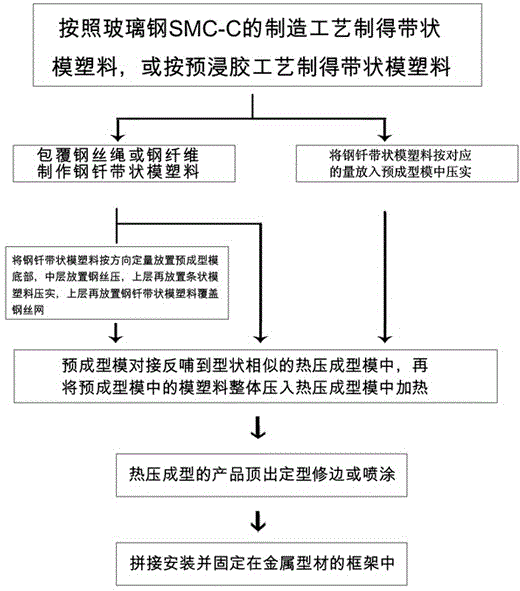

[0022] 2. According to the manufacturing process of FRP SMC-C or prepreg process, the continuous fiber tape molding compound is produced;

[0023] 3. Put the continuous fiber strip molding compound into the preforming mold according to the corresponding amount and compact it;

[0024] 4. Butt-feed the preformed film filled with continuous fiber ribbon molding compound into a thermocompression molding mold with similar shape, and then press the continuous fiber ribbon molding compound in the preformed film into the thermocompression molding mold as a whole .

Embodiment 2

[0026] 1. Use glass fiber reinforced plastic raw materials, steel fiber wire, and steel wire rope;

[0027] 2. According to the manufacturing process of FRP SMC-C or prepreg process, the continuous fiber tape molding compound is produced;

[0028] 3. Quantitatively divide the continuous fiber tape molding compound into strip molding compound according to the direction, and wrap the steel wire rope with the strip molding compound to obtain the steel fiber tape molding compound;

[0029] 4. Put the steel fiber strip molding compound into the preforming mold according to the corresponding amount and compact it;

[0030] 5. Butt-feed the preformed film filled with steel fiber strip molding compound into a thermocompression molding mold with similar shape, and then press the molding compound in the preformed film into the thermocompression molding mold as a whole.

Embodiment 3

[0032] 1. Use glass fiber reinforced plastic raw materials, steel fiber wire, steel wire rope, and steel wire mesh;

[0033] 2. According to the manufacturing process of FRP SMC-C or prepreg process, the continuous fiber tape molding compound is produced;

[0034] 3. Quantitatively divide the continuous fiber tape molding compound into strip molding compound according to the direction, and wrap the steel wire rope with the strip molding compound to obtain the steel fiber tape molding compound;

[0035] 4. Put the steel fiber strip molding compound on the bottom of the preforming mold quantitatively according to the direction, place the steel mesh on the middle layer for compaction, and place the steel fiber strip molding compound on the upper layer to cover the steel mesh;

[0036] 5. Butt-feed the preformed film filled with steel fiber ribbon molding compound into a thermocompression forming mold with similar shape, and then press the molding compound in the preformed film in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com