Modified emulsified asphalt fiber synchronous pavement surface dressing construction method

A technology of synchronous crushed stone seal and emulsified asphalt, which is applied to the cohesive pavement, road, pavement details and other directions paved on site, can solve the problems of large maintenance funds and other problems, and achieve fast construction speed, good water sealing effect, The effect of preventing infiltration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

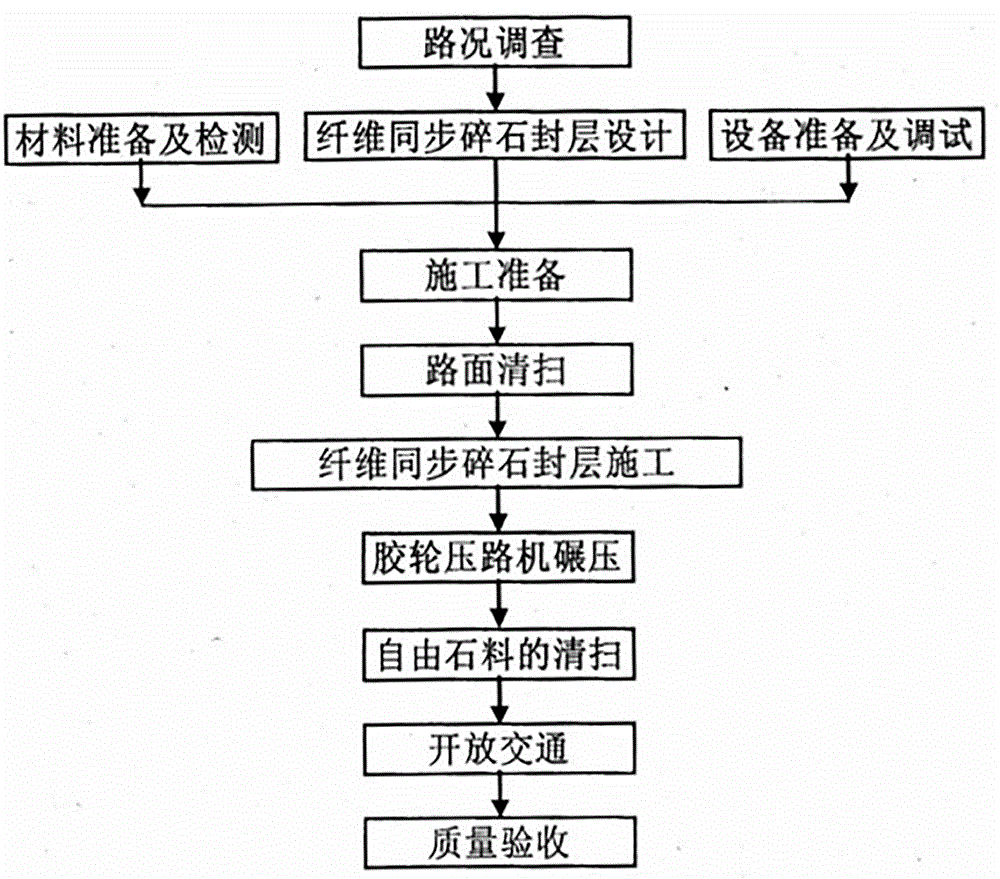

[0026] figure 1 The construction flow chart of the construction method of the modified emulsified asphalt fiber synchronous gravel seal layer provided by the present invention.

[0027] The modified emulsified asphalt fiber synchronous crushed stone seal layer construction method provided by the invention is suitable for the lower seal layer of roads at all levels, especially for the surface wear layer of the roads of the first grade and below, and also suitable for the second grade and below the second grade The road surface is a good way to quickly restore the function of the road surface.

[0028] The process principle of the modified emulsified asphalt fiber synchronous gravel seal layer construction method provided by the present invention is:

[0029] 1. High stress absorption and stress diffusion, super crack resistance.

[0030] The fiber sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com