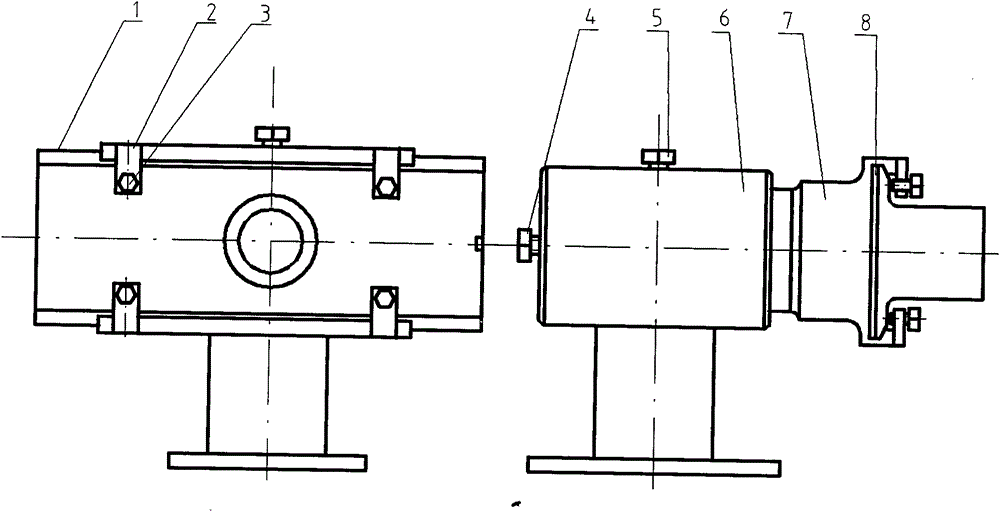

Sliding plate type exhaust pipe joint for small engine test bench

A test bench and engine technology, which is applied in the direction of engine testing, pipe/pipe joint/pipe fitting, machine/structural component testing, etc. It can solve the problems of cumbersome disassembly and assembly, and achieve the effect of improving work efficiency and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

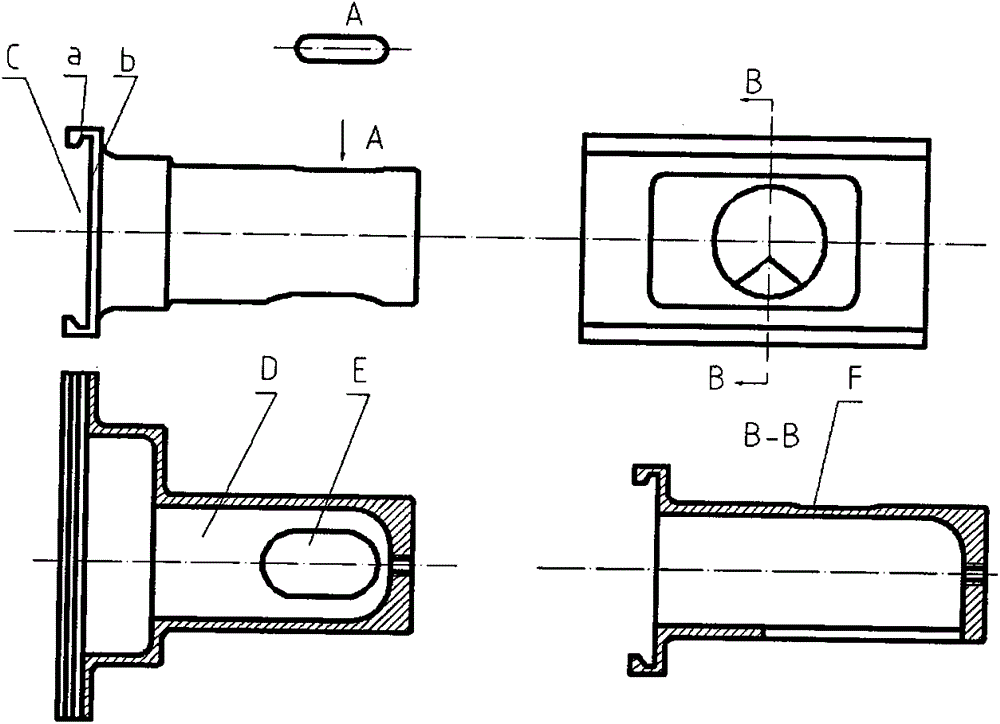

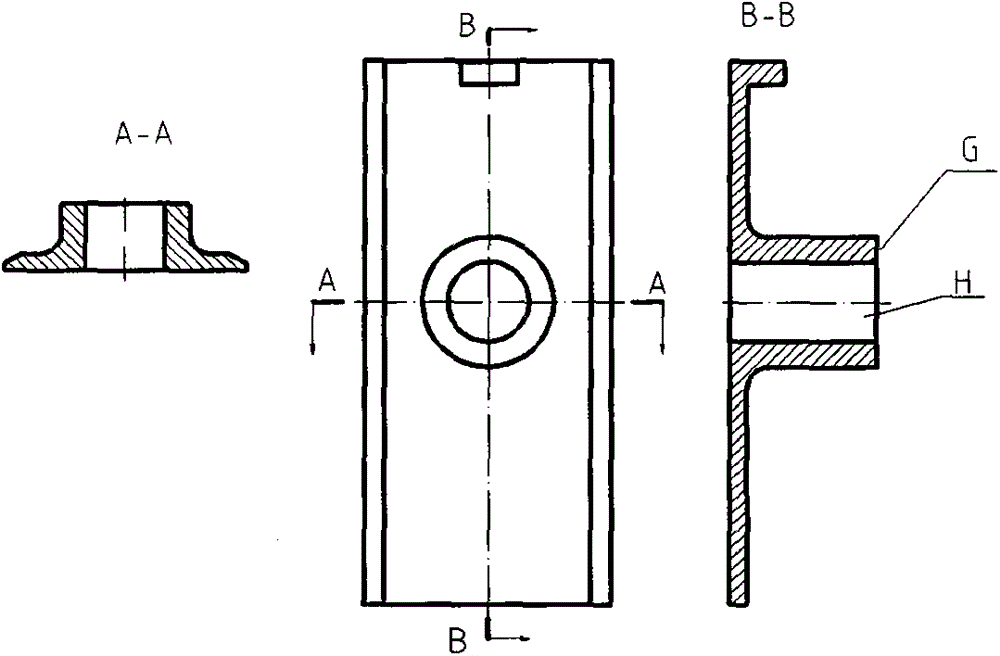

[0012] There is a chute C at the front end of the movable joint 7 of the exhaust pipe, through which the sealing plane b and the conical surface a are used to seal the exhaust gas of the engine with the gasket 8 and the slide plate 1; there is a groove F on the upper part of the movable joint 7 of the exhaust pipe, Screw the bolt 5 into the exhaust pipe seat 7 and embed it in the groove F above the movable joint 7 of the exhaust pipe, so that the movable joint 7 of the exhaust pipe is fixed on the exhaust pipe seat 6 of the test bench.

[0013] The slide plate 1 can move left and right in the chute C of the movable joint 7 of the exhaust pipe to adapt to the exhaust ports of the cylinder heads at different outlet positions of different types of engines. The bolt 3 on the slide plate positioning block 2 fixes the slide plate 1 and the movable joint 7 of the exhaust pipe.

[0014] Screw in the bolt 4 at the rear end of the movable joint 7 of the exhaust pipe, push the slide plat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap