Backlight module and manufacturing method

A technology of a backlight module and a manufacturing method, which is applied to the display backlight module and its manufacturing field, can solve the problems of reducing quantum conversion efficiency, affecting the backlight effect, aperture, etc., and achieves the effect of maintaining the quantum conversion efficiency and improving the backlight effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

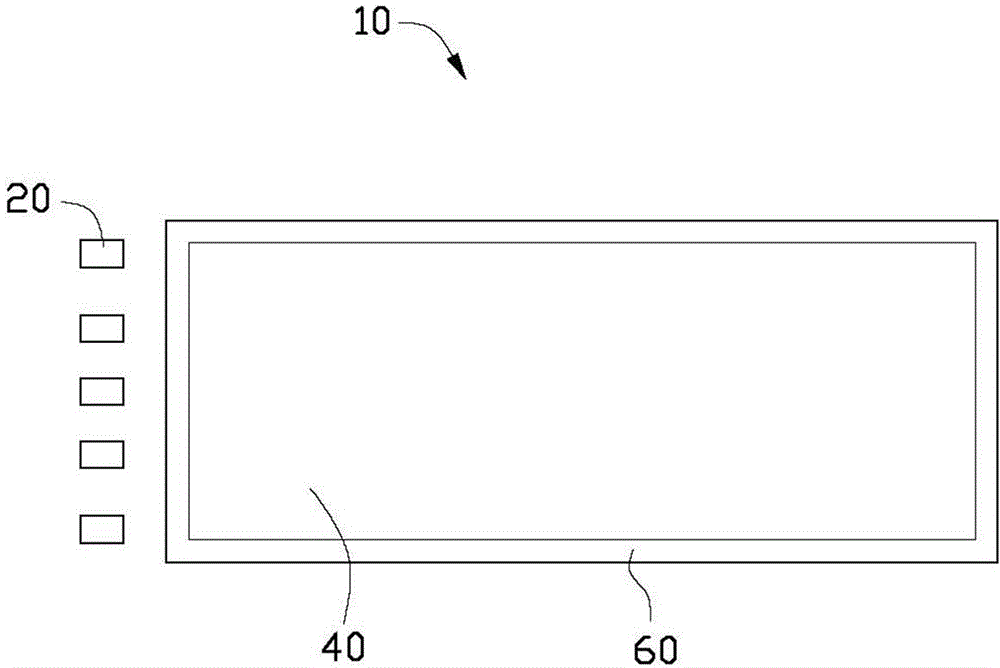

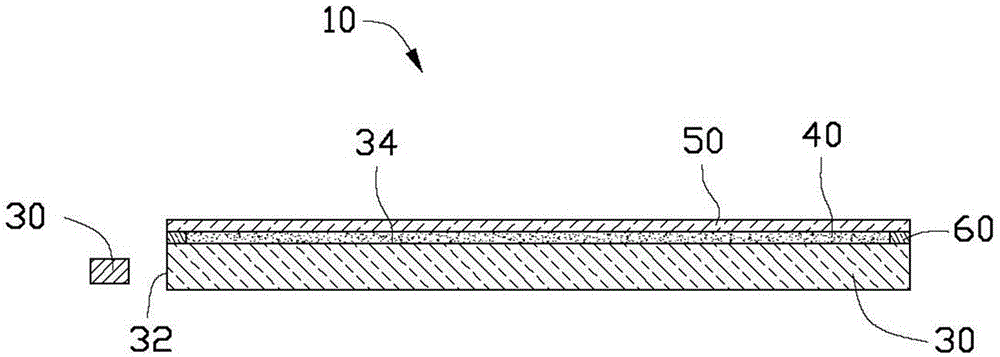

[0013] see Figure 1-2 , shows a backlight module 10 according to an embodiment of the present invention. The backlight module 10 includes a plurality of light sources 20 , a substrate 30 , a quantum dot film 40 formed on the substrate 30 , a cover plate 50 covering the quantum dot film 40 and a sealing layer 60 surrounding the quantum dot film 40 .

[0014] The light source 20 is made of semiconductor material, which can be excited by electric current to emit visible light. In this embodiment, the light source 20 includes a plurality of blue light emitting diodes. The LEDs are arranged in a row to emit light toward the side of the substrate 30 .

[0015] The substrate 30 is made of transparent materials such as glass, polycarbonate, and polymethyl methacrylate. The substrate 30 is a rectangular board, which includes a light incident surface 32 and a light exit surface 34 adjacent to the light incident surface 32 . In this embodiment, the light incident surface 32 is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com