Condensing lens and lamps

A technology of condensing lens and point light source, applied in the field of condensing lens, can solve problems such as affecting the condensing effect, and achieve the effect of ensuring the condensing effect and facilitating injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

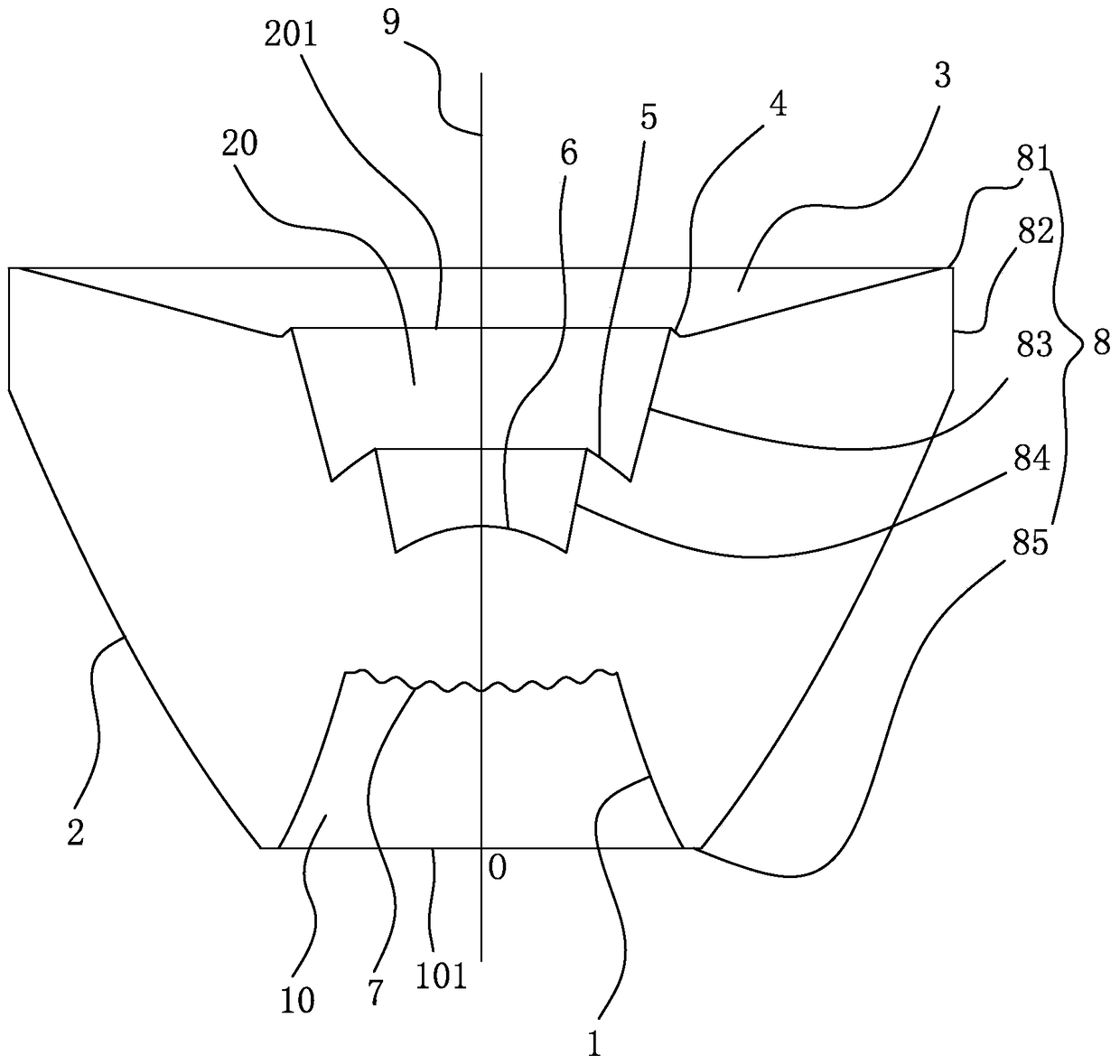

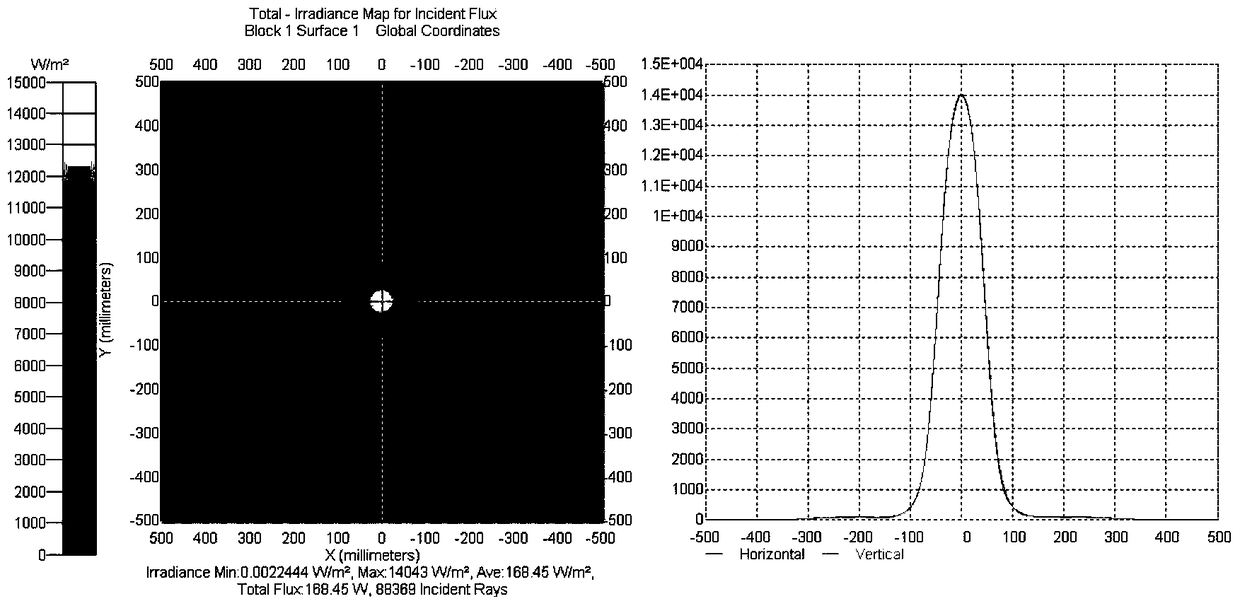

[0029] see Figure 1 to Figure 4 , figure 1 It is the partially cut-away structural intention of the condenser lens of the present invention. figure 2 for figure 1 Schematic diagram of the light output of the condensing lens and the light source. image 3 It is the light shape effect diagram of the combination of the condenser lens and the light source of the present invention. Figure 4 It is a light distribution curve diagram of the combination of the condenser lens and the light source of the present invention. The condensing lens of the present invention is a structure of revolution around an optical axis 9, the condensing lens has a first cavity 10 with a bottom opening 101 and a second cavity 20 with a top opening 201, the second cavity 20 A point light source (not shown) may be installed at the central point O of the bottom op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com