Dust-removing device of cooker

A stove and ash falling technology, applied in lighting and heating equipment, etc., can solve the problems of incomplete cleaning, pollution, danger, etc., and achieve the effect of convenient ash cleaning process, convenient recycling, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below with reference to the drawings and embodiments.

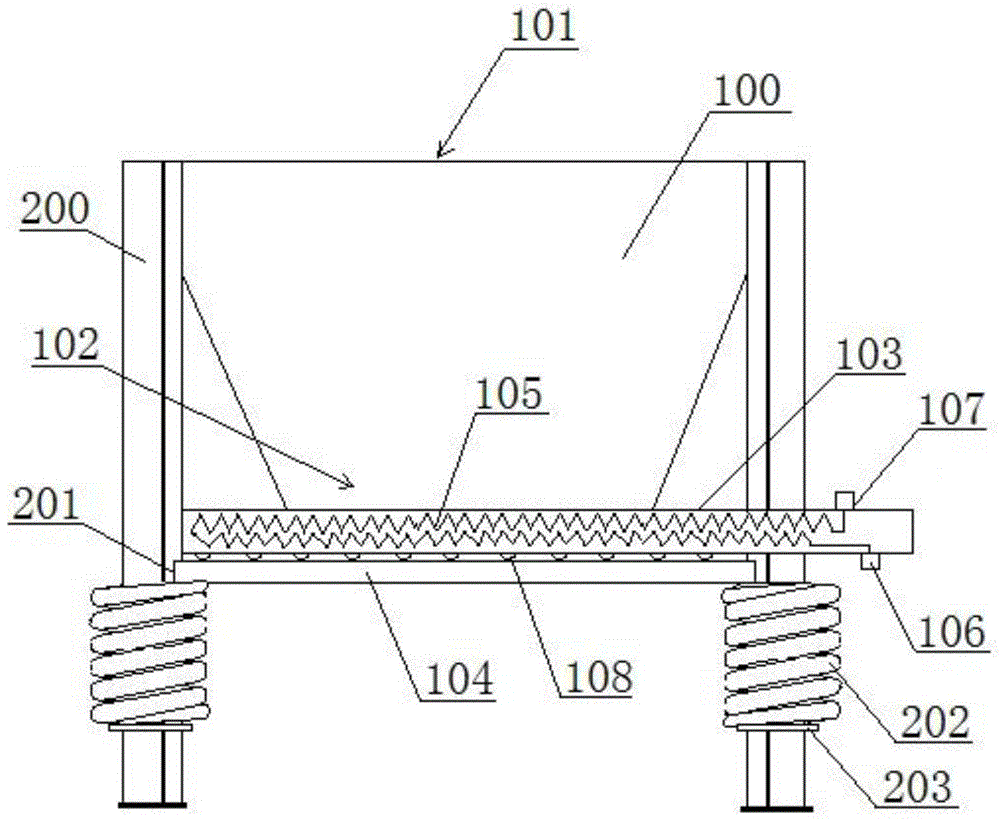

[0017] Such as figure 1 , A stove ash removal device, comprising an ash dropping trough 100, the ash dropping chute 100 is installed on a support frame, the support frame includes a plurality of support rods 200, the ash dropping chute 100 is correspondingly set up and down with an ash inlet 101 With the ash outlet 102, the ash outlet 102 is equipped with a drawing plate 103, the bottom of the drawing plate 103 is supported by a supporting plate 104, the drawing plate 103 is made of heat conductive material, and the middle of the drawing plate 103 is provided with a transmission plate. A hot cavity, a metal water pipe 105 is arranged inside the heat transfer cavity, the water inlet 106 and the water outlet 107 of the metal water pipe 105 are respectively arranged at one end of the drawing plate 103, and fuel ash falls from the grate The ash trough 100 and the drawing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com