Inclined groove permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and chute, applied in the direction of synchronous machine parts, magnetic circuit, electric components, etc., can solve problems such as error-prone noise, torque drop, high energy consumption, etc., to solve heat accumulation and improve working torque Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

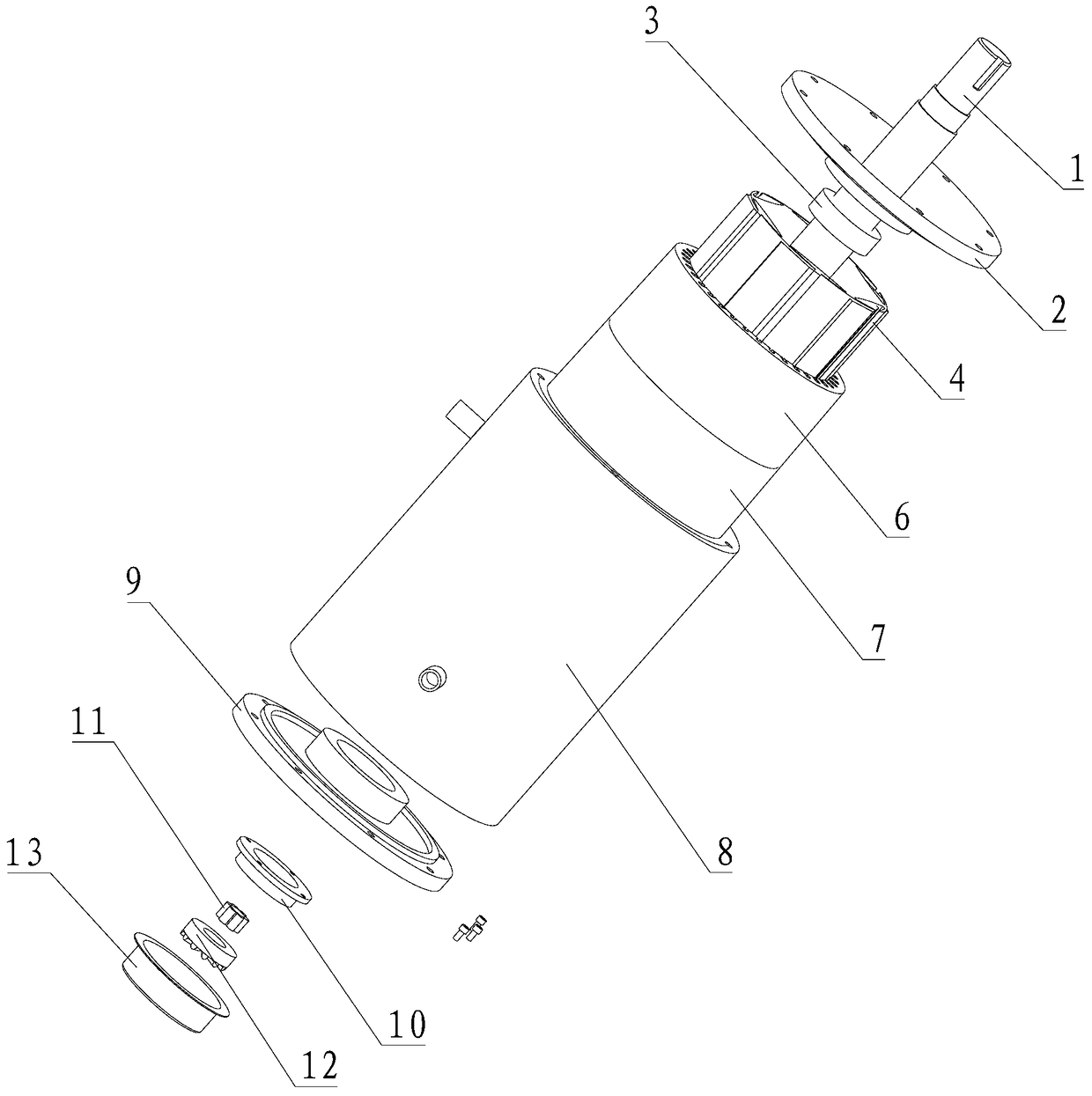

Method used

Image

Examples

Embodiment 1

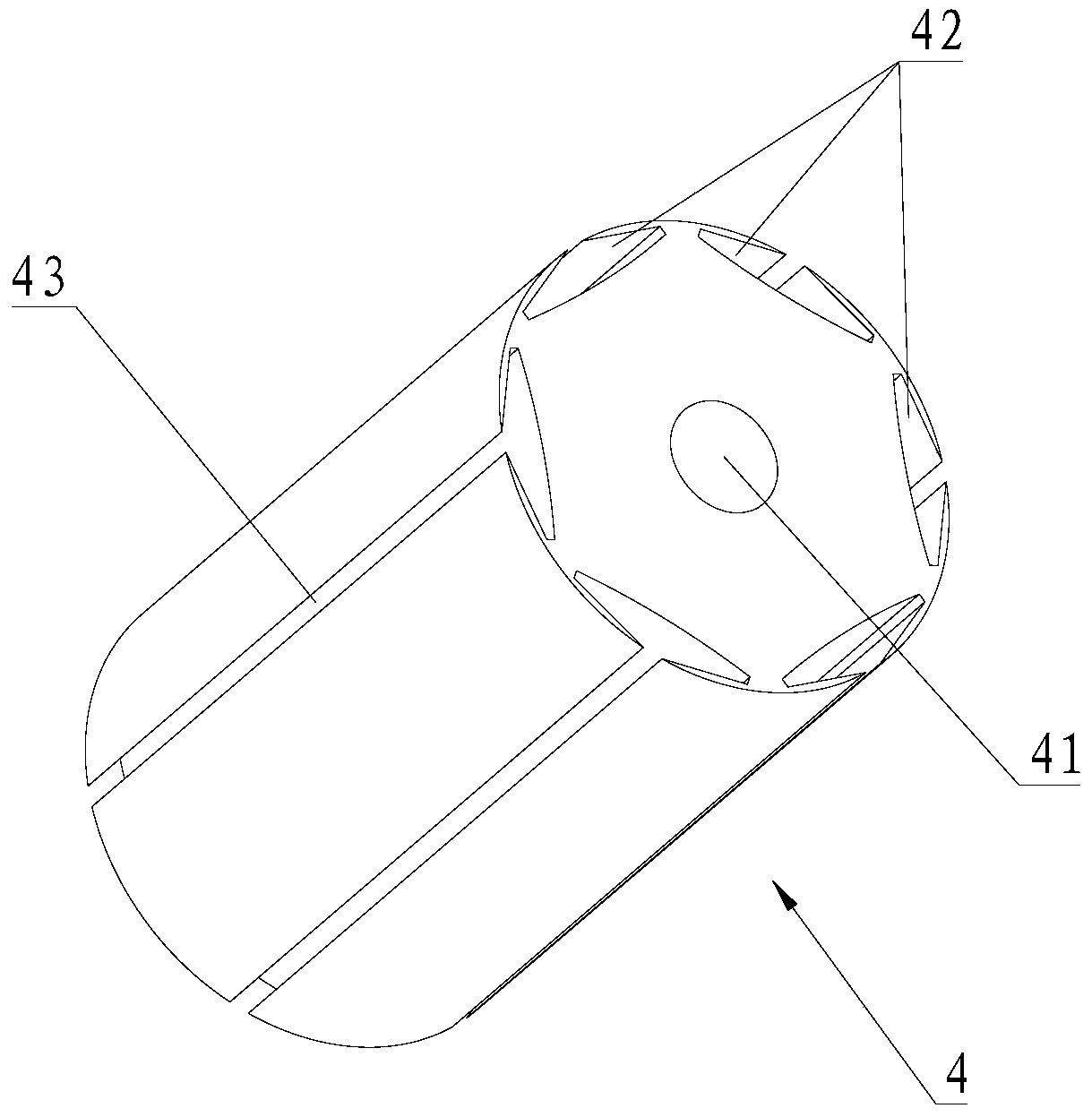

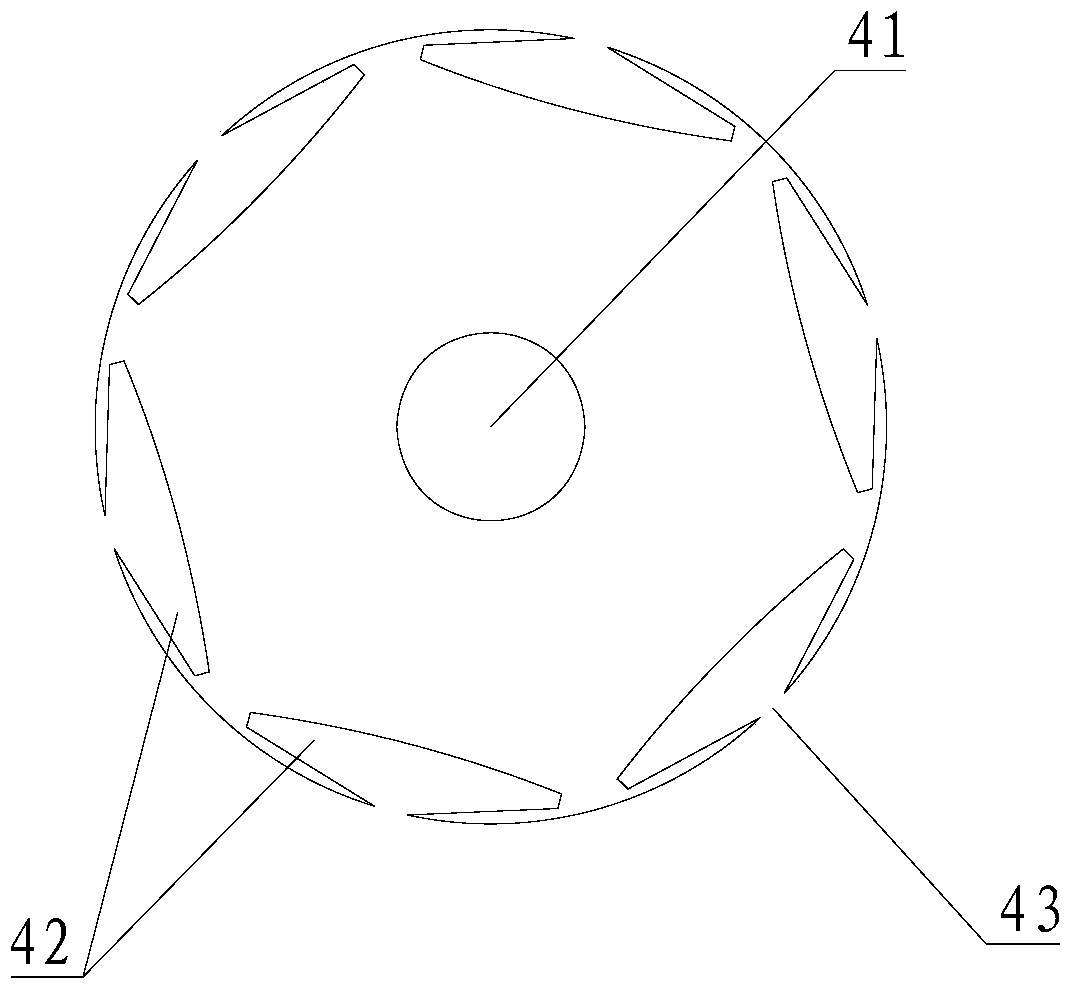

[0032] In the above, the magnet 5 is surrounded by the bottom surface 52 and the two side surfaces 51 which are successively connected; Correspondingly, and when the magnet 5 is put into the magnet accommodating cavity 42 , the connecting ends of the two side surfaces 51 correspondingly extend to the through groove 43 on the side surface of the rotor 4 .

[0033] In this embodiment, the use of approximately triangular-shaped magnets can not only increase the magnetic area, but also increase the refraction point of the magnetic column line magnetic circuit, which can effectively increase the torque, so that it can be compared with other flat and tile-shaped motors under the same power. Compared with the magnet, it produces a larger torque.

Embodiment 2

[0035] In the above, the bottom surface 52 of the magnet 5 is convex in an arc shape; the bottom surface 52 is connected to the two side surfaces 51 through the thick surface 53 .

[0036] Through a large number of experiments, it is found that increasing the arc of the bottom surface of the magnet can effectively solve the problem of high heat generation in the motor process. Increasing the arc bottom surface can mainly reduce the magnetic pulsation, and then achieve the purpose of reducing the heat generation. In this embodiment, the bottom surface of the magnet is further optimized into a convex arc shape, which can better ensure the effect and consume more energy, because the magnetic field magnetic circuit is unbalanced, strong and weak, and the arc shape is designed as What is important is the balance of the magnetic field and the above-mentioned effects.

Embodiment 3

[0038] Among the above, it has been obtained through a large number of experiments that the effect of designing the thick surface 53 of the magnet with a width of 1-4mm is the best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com