Dirt cleaning plastic helical device strengthened by heat-transfer fluid power

A heat transfer fluid and screw device technology, applied in the field of dirt cleaning plastic screw devices, can solve problems such as insufficient cleaning torque, cleaning wear of steel wire helix, wear of steel wire helix and heat transfer tube wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

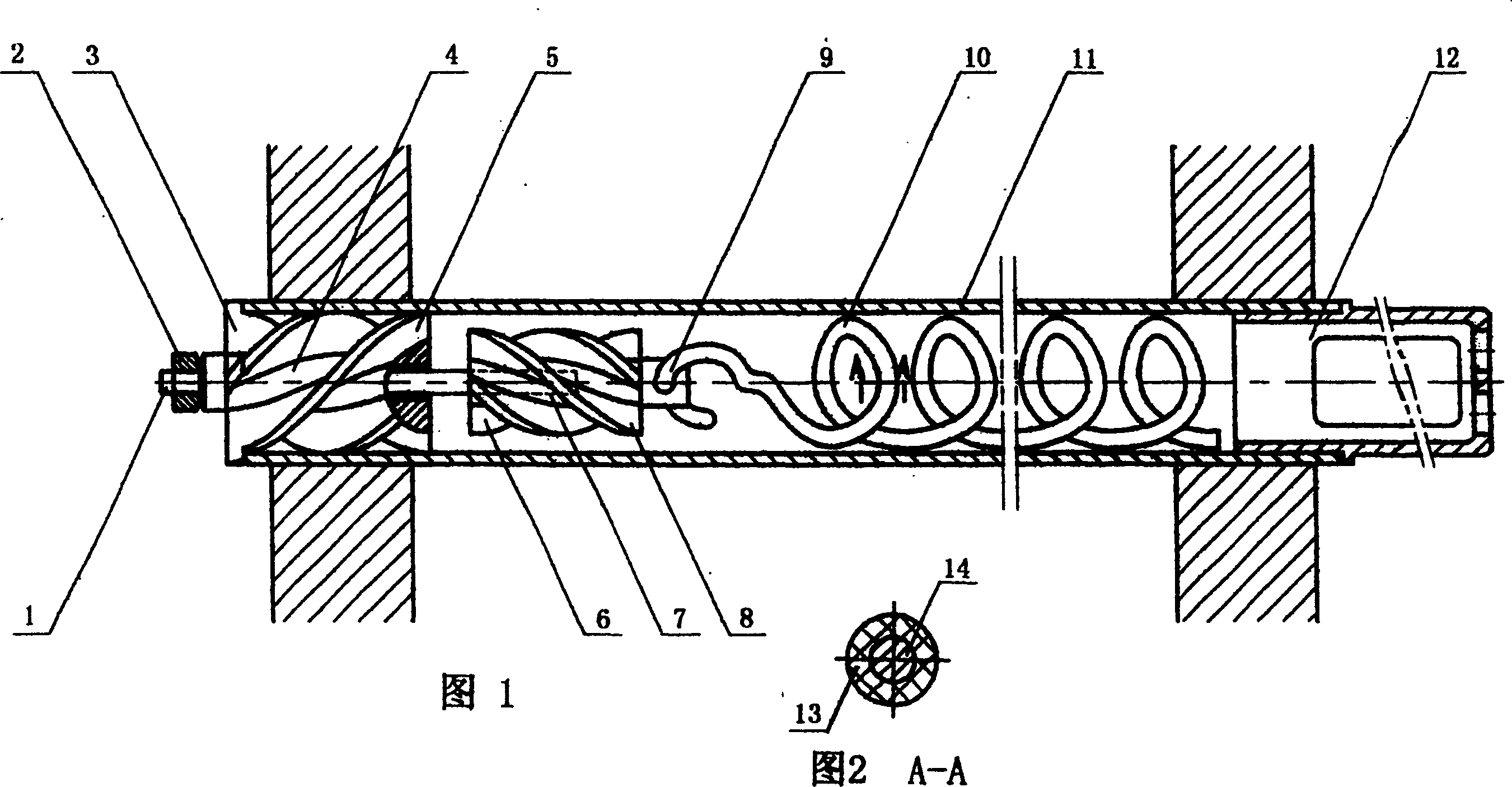

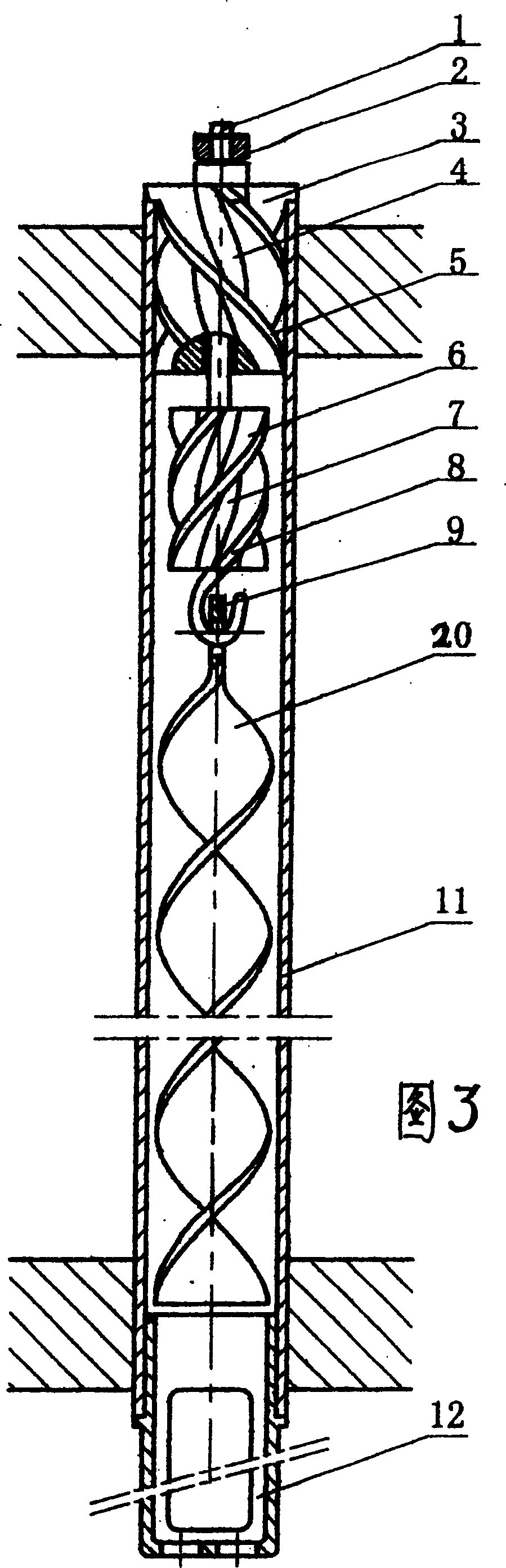

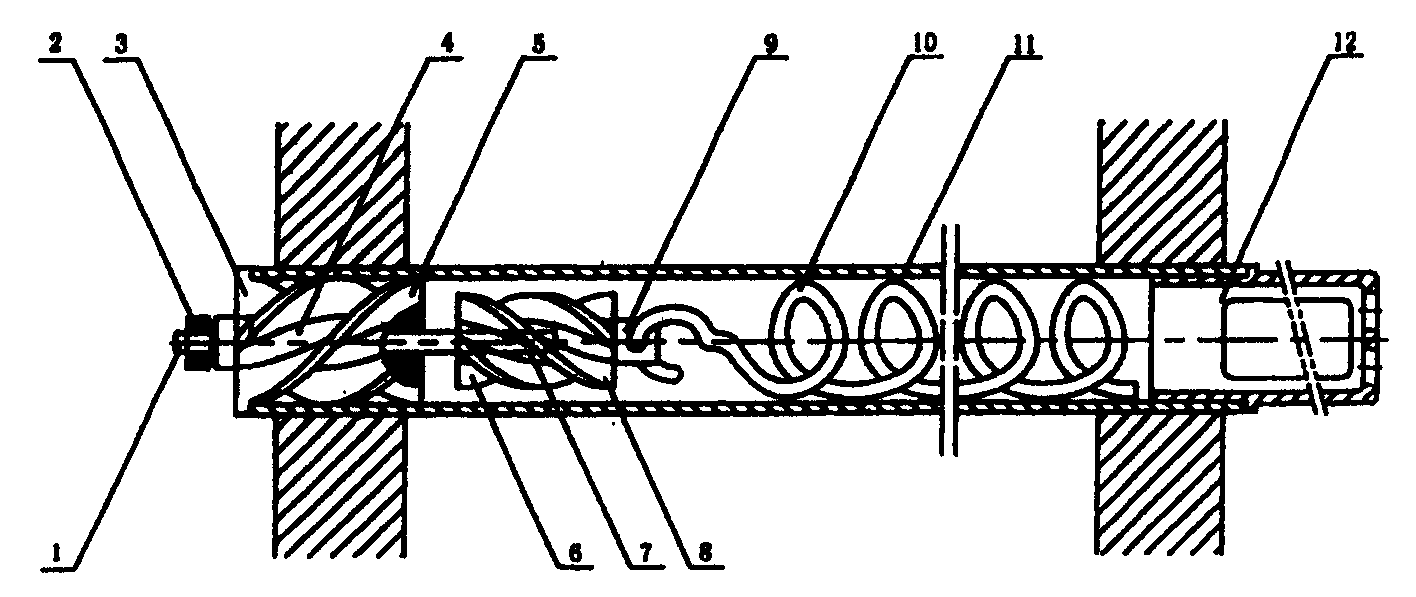

[0010] The present invention will be described in further detail below in conjunction with accompanying drawing 1 , accompanying drawing 2 and accompanying drawing 3.

[0011] In the figure 1. Shaft 2. Grinding head 3. Spiral nozzle fixing device 4. Core barrel 5. Spiral piece 6. Spiral power wheel 7. Wheel hub 8. Spiral blade 9. Spiral head 10. Plastic-coated helix 11 Heat transfer tube 12. Tail sleeve 13. Plastic cladding 14. Metal helix 20. Spiral plastic tie

[0012] A heat-transfer hydrodynamically enhanced dirt-cleaning plastic spiral device, in which a plastic-wrapped spiral 10 combined with a metal spiral 14 and a plastic cladding 13 is arranged in a heat transfer tube 11 . The plastic wrapped helical wire 10 is fixed on the helical nozzle fixing device 3 through the helical head 9 through the helical power wheel 6, the rotating shaft 1 and the grinding head 2. After the spiral plastic tie 20 is connected with the rotating shaft 1 through the spiral head 9, it is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com