A workpiece cover disassembly machine

A dismantling machine and cover technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of small working torque, low production utilization rate, complex structure, etc., and achieve strong working torque, low price and good structure small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

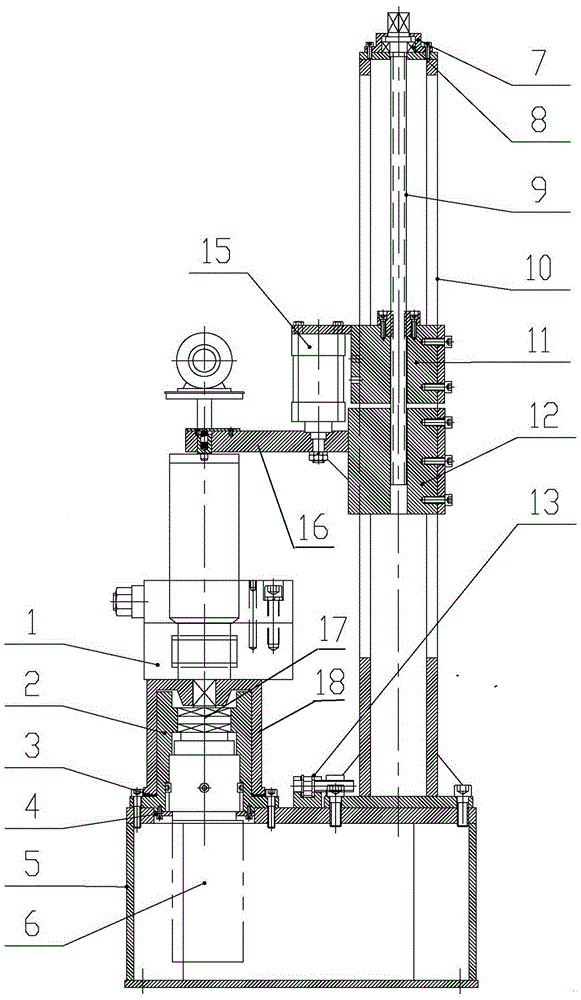

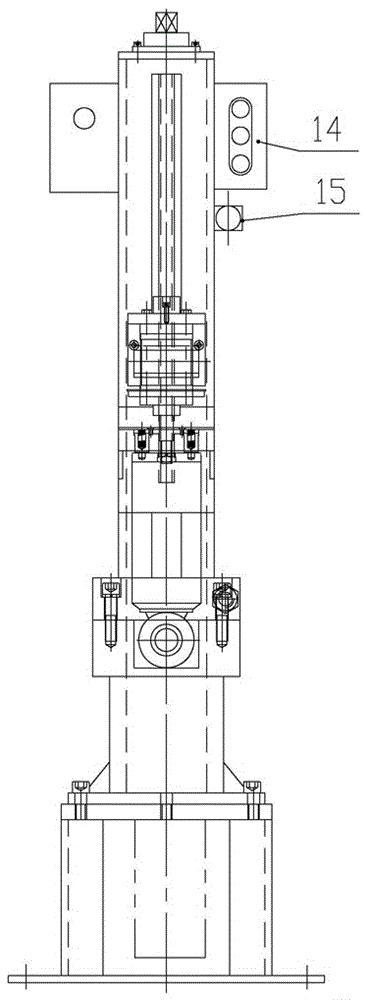

[0050] A shock absorber gland dismounting machine, such as figure 1 and 2As shown, the shock absorber gland tightening machine is overly complicated with electrical, mechanical, hydraulic (oil motor, hydraulic clamp, 630L large fuel tank), light control, computer input touch screen, pneumatic lifting of the spindle tightening head, and intelligent torque sensing Among the 7 major systems and huge structures, only the pneumatic item is retained, and all other system structures are cut off to greatly simplify the system and reduce the overall structure. At the same time, use the P1D-LP-2000 constant torque electric wrench to remove the tail, fix it with the centering sleeve and the lock ring, pass through the base table from top to bottom as the heart, and fix it on the base. Seats together as a powered rotary vise. Because the speed is only 6 rpm, plus the total weight of each component and the pneumatic pressure is about 200 kg, and there is no lateral force, brass pads and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com