Microwave processing unit for pavement recycling and asphalt pavement production

A technology of asphalt and mixed asphalt, which is applied in the field of asphalt production and can solve the problems of performance degradation of new HMA

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

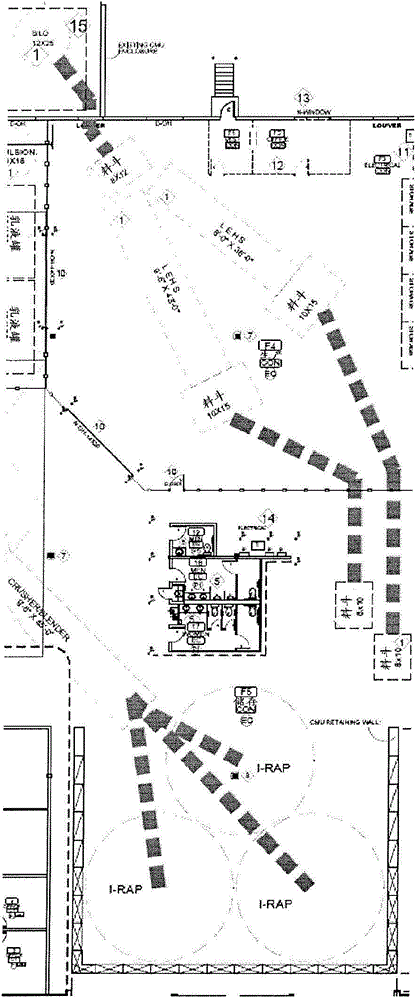

[0013] The present invention includes equipment for the production of low energy asphalt pavements utilizing test and design equipment with low energy heating systems using microwave technology and manufacturing methods ("LEHS") for use up to 100% recycled asphalt pavements ("RAP") in order to convert it into a High Performance Hot Mix Asphalt ("HMA"), which outperforms any type of prior art asphalt product. LEHS uses very little energy and produces virtually undetectable amounts of pollution (when compared to existing methods of producing HMA).

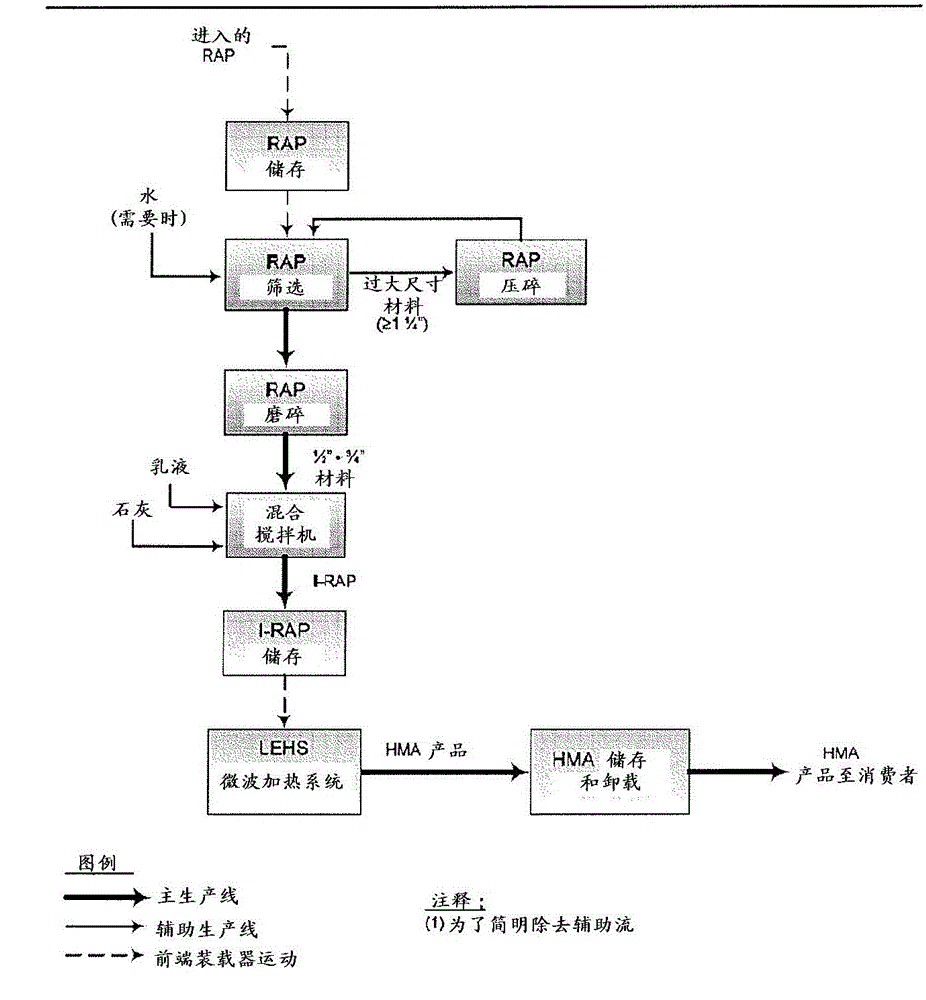

[0014] Typically, methods include the following steps:

[0015]

[0016] The method begins by recovering RAP material from roads, parking lots or other paved surfaces. The method enables the use of varying amounts of RAP, including up to 100% RAP, which enables maximum re-use or regeneration of the product. The emulsion is added to the product, and as described in more detail below, the emulsion can make up about 5% of the produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com