Supply rack for a tower, tower with a supply rack and method for building a supply rack inside a tower

An internal space, frame-type technology, applied in the field of supply racks, can solve problems such as the limitation of the possibility of setting up the inside of the tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

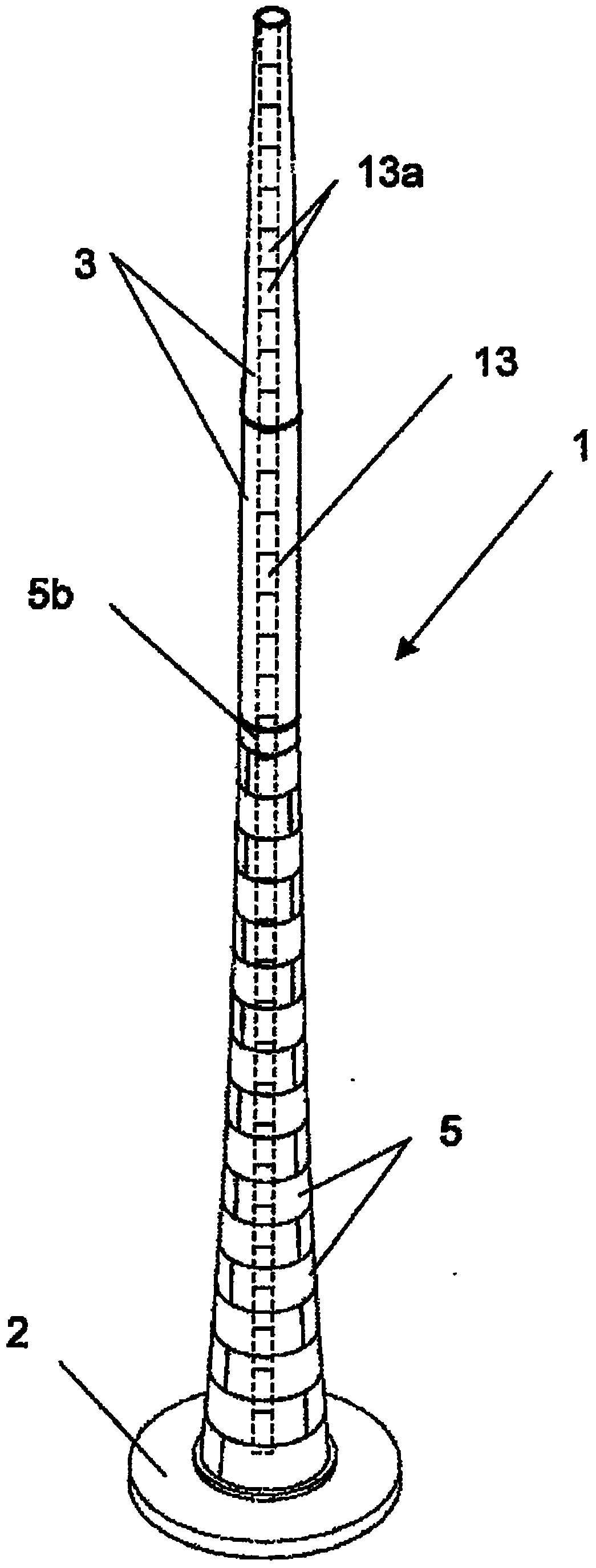

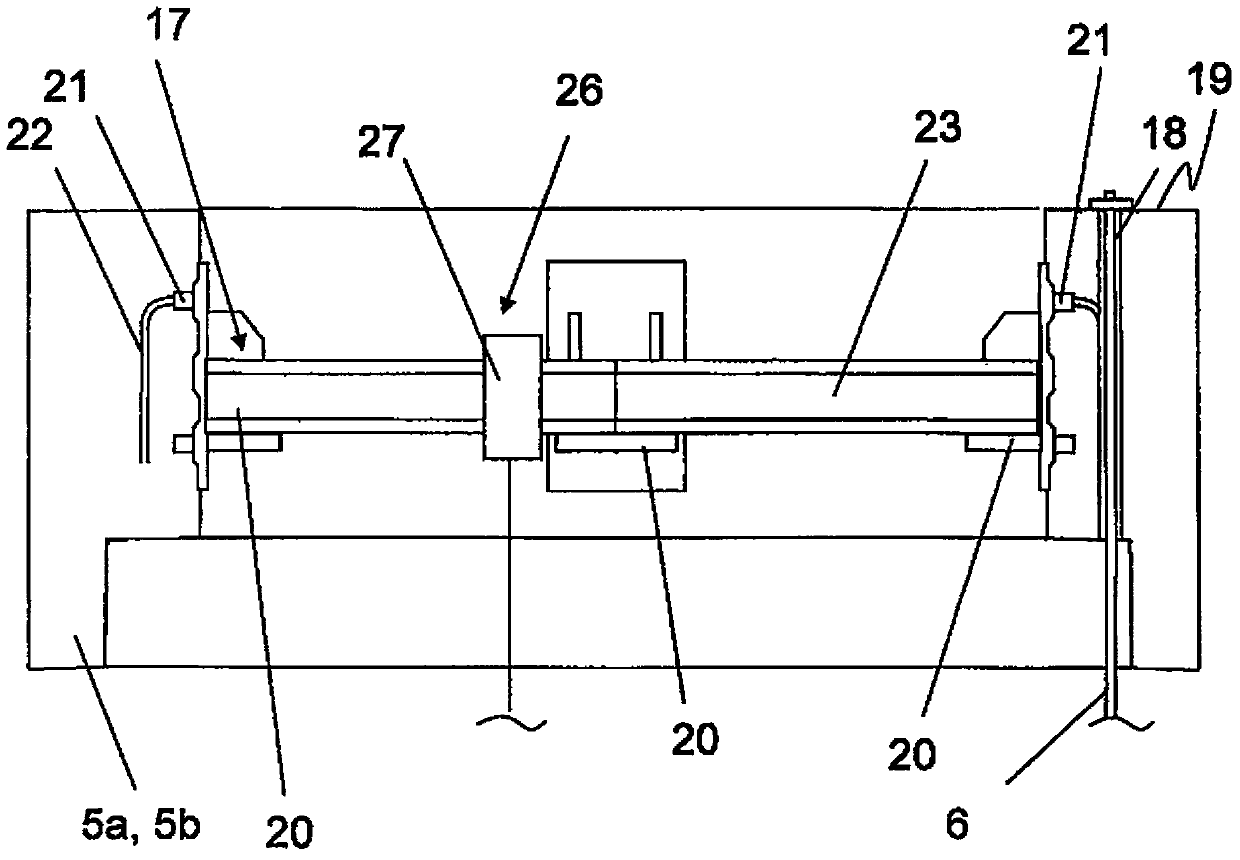

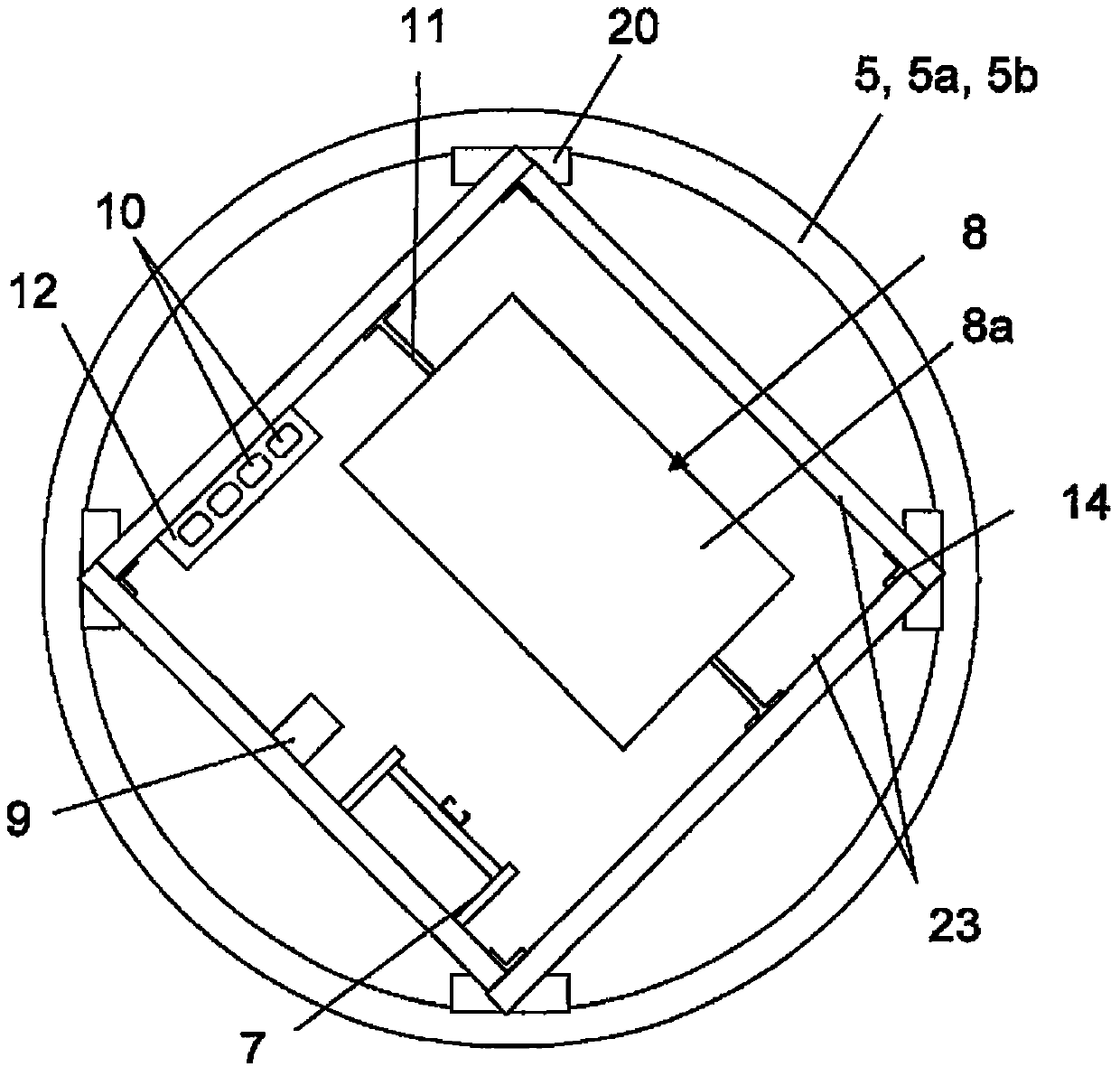

[0040] figure 1 A perspective overview illustration of a tower 1 according to the invention is shown, which is embodied above as a wind power tower. The tower 1 consists of a plurality of ring-segment-shaped prefabricated concrete elements 5 , which are each assembled to form a concrete ring and are arranged one above the other on the base 2 of the tower 1 . The tower is constructed as described above as a hybrid tower and has additional tubular steel segments 3 above the prefabricated concrete elements 5 , which are arranged on transition pieces 5 b. The transition pieces 5b are used here not only for the connection of the steel sections 3 to the precast concrete elements 5, but also for the clamping mechanisms 6 (see figure 2 ) by means of which clamping means a plurality of prefabricated concrete elements are connected to each other and fixed on the base 2 and by means of which a prestressing force can be exerted on the tower section formed by the prefabricated concrete e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com