Improvements to radius inspection tools

A workpiece and ultrasonic technology, applied in the direction of material analysis, measuring devices, instruments, etc. using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as difficulties, time-consuming, and affecting signal characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

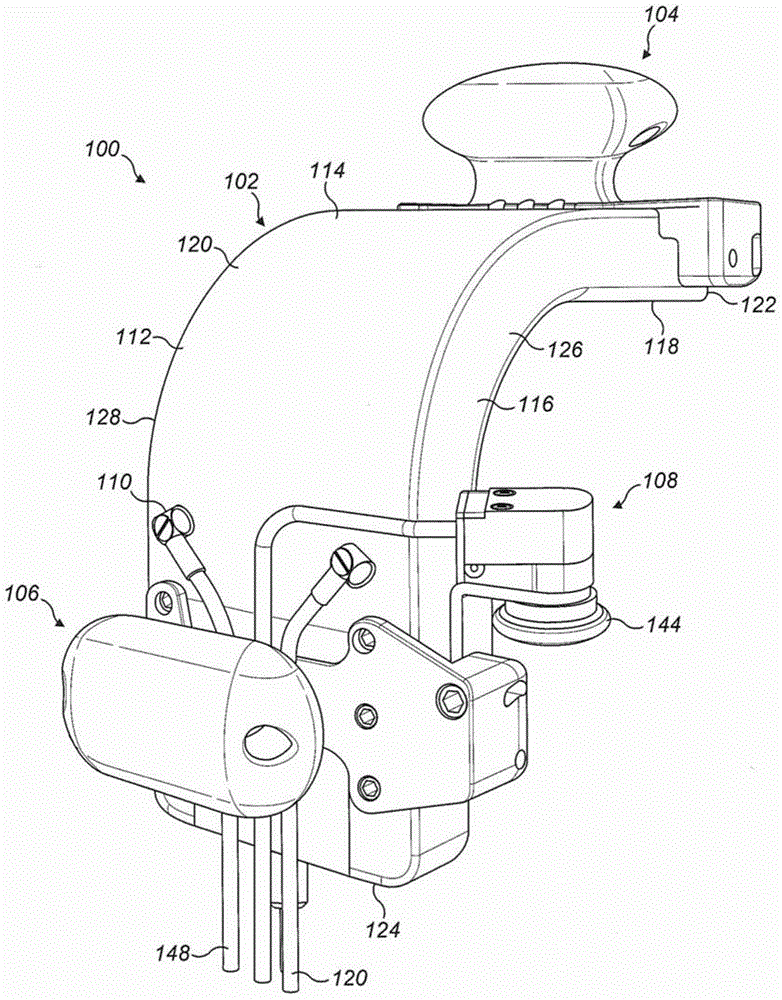

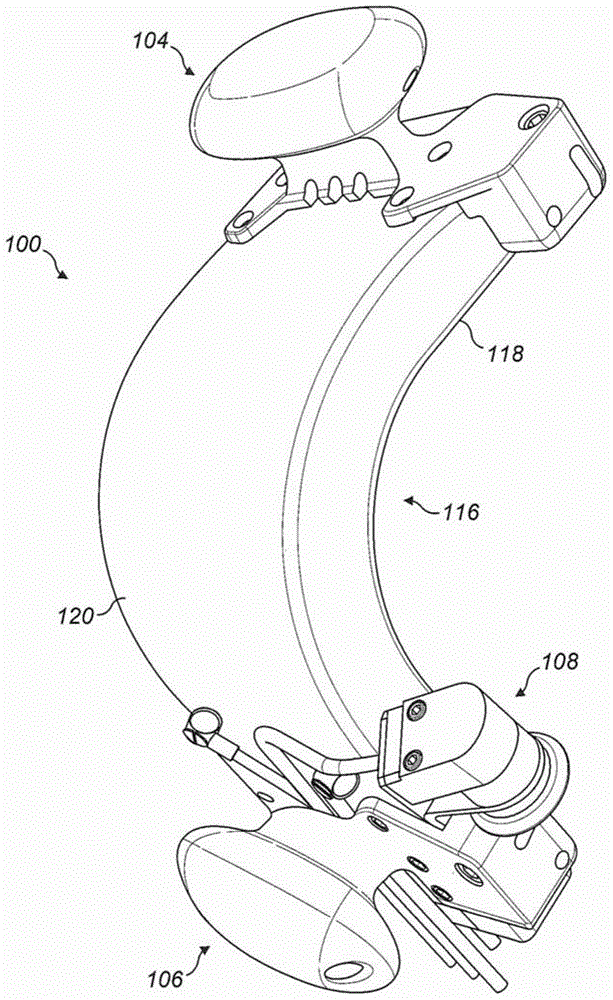

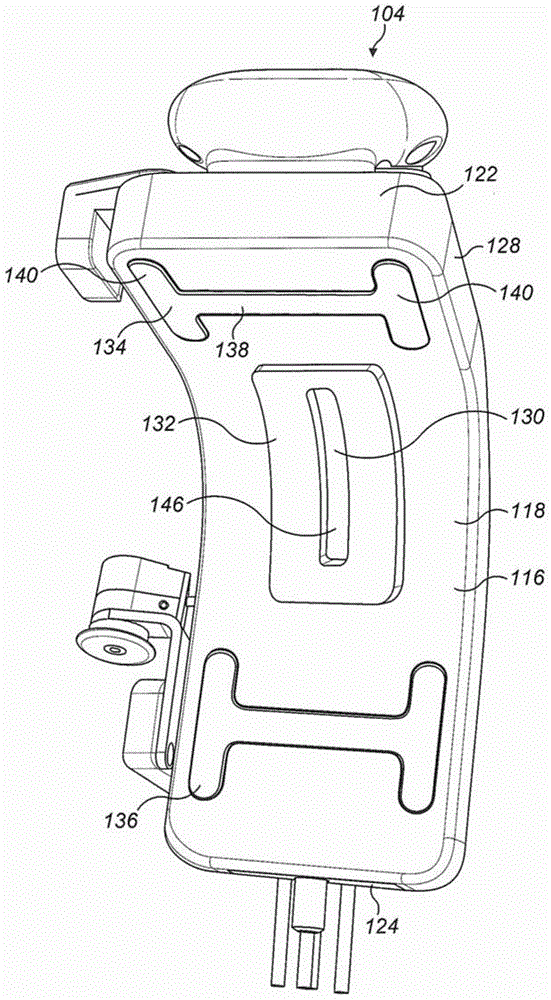

[0060] Figures 1 to 4d A first ultrasonic inspection probe 100 is shown in . The probe 100 includes a housing 102 , a first handle 104 , a second handle 106 and a rotary encoder 108 . The frame 102 includes a generally curved cross-section and a prismatic body 116 . The body 116 includes a first planar portion 110 , a 90-degree rounded portion 112 , and a second planar portion 114 . A planar portion 110 and a planar portion 114 extend from either end of the rounded portion 112 .

[0061] The probe 100 is configured to move along the elongated rounded workpiece in the axial direction of the rounded portion 112 . The terms “axial” and “radial” are used herein with respect to the radius 112 .

[0062] The main body 116 defines a workpiece facing surface 118 on one side and a frame loading surface 120 on an opposite side. In the illustrated embodiment, the body 116 has a female workpiece facing surface adapted to guide a male workpiece. It should be appreciated that the bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com