Automatic knife replacing device for food cutter

A technology of automatic knife changing and cutting machine, which is applied in the fields of food forming, food science, metal processing, etc., can solve the problem that the cutting machine cannot be applied, and achieve the effect of improving work efficiency and simplifying the operation of knife changing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

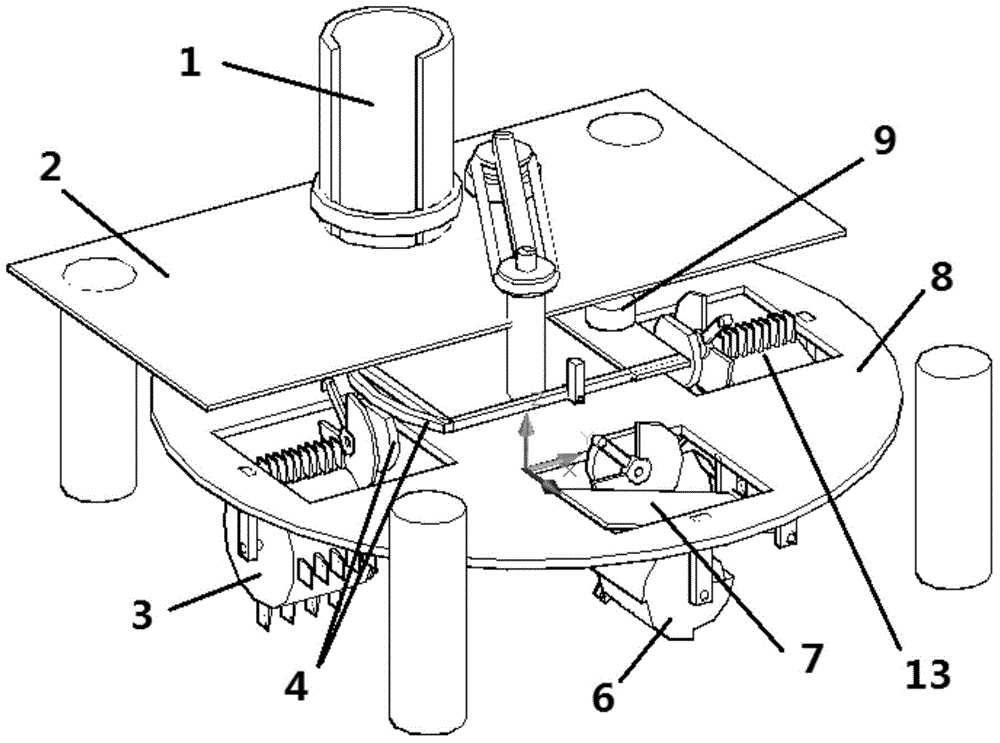

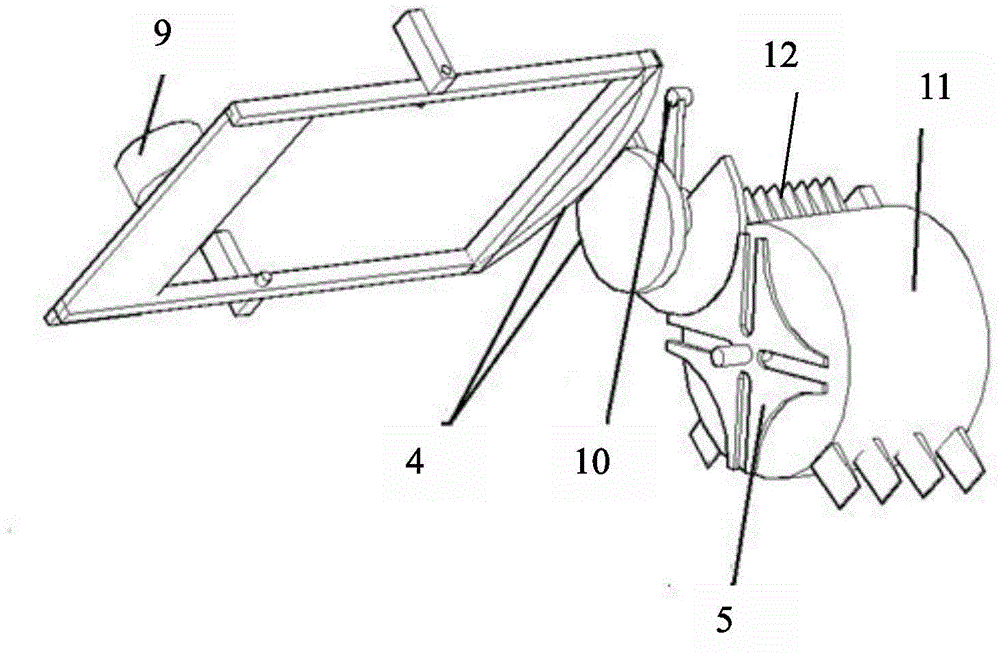

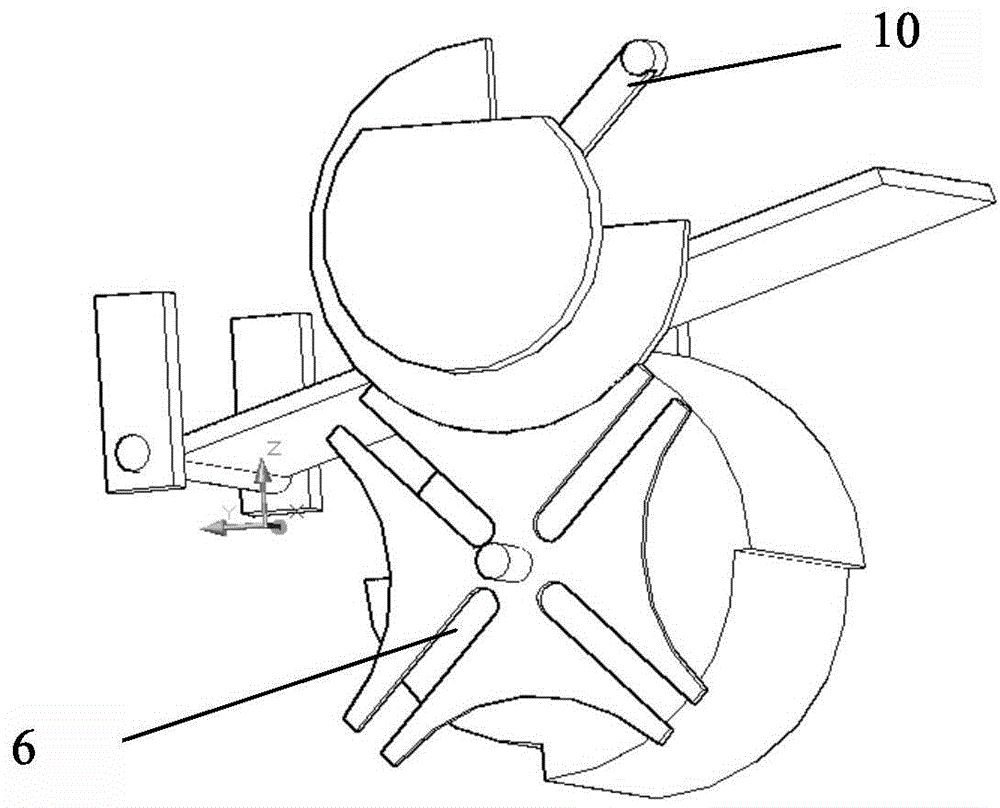

[0031] Both the first tool post 3 and the second tool post 13 are provided with three working stations 12 and an empty station 11, and a plurality of tools with the same interval are arranged on the working station 12 and the interval is different from other working stations. The distance between the cutters on the position 12 is different. The third tool rest 7 is a cutting knife, which is provided with 3 working positions. The height of the cutting knife can be adjusted by adjusting the working positions. The second tool rest 13 and the first tool rest 3 At an angle of 180°, the third tool holder 7 and the first tool holder 3 are at an angle of 270°. The original material is put into the material barrel 1, and the turntable 8 rotates to drive the knives on the first knife holder 3, the second knife holder 13 and the third knife holder 7 to cut the food. According to the different tool selection, the original food material can be Processed into pieces, strips, and D-shaped fin...

Embodiment 2

[0036] Both the first tool post 3 and the second tool post 13 are provided with three work stations 12 and an empty station 11, a total of four stations. The working station 12 is provided with a plurality of tools with the same interval and the interval is different from the tool intervals on other working stations 12. The third tool rest 7 is a cutting tool, which is provided with 4 working stations, By adjusting the working position to adjust the height of the cutting knife, the second tool rest 13 and the first tool rest 3 form an angle of 180°, and the third tool rest 7 and the first tool rest 3 form an angle of 270°. The original material is put into the material cylinder 1, and the turntable 8 rotates, driving the knives on the first, second and third knife holders to cut the food. According to the different selection of knives, the original food materials can be processed into slices and strips. , Ding-shaped finished materials. Finally, it is collected by the portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com