A semi-automatic shoe material delivery equipment

A semi-automatic, shoe material technology, applied in footwear, shoe-making machinery, apparel, etc., can solve the problems of lightening and unfavorable labor intensity of feeding personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

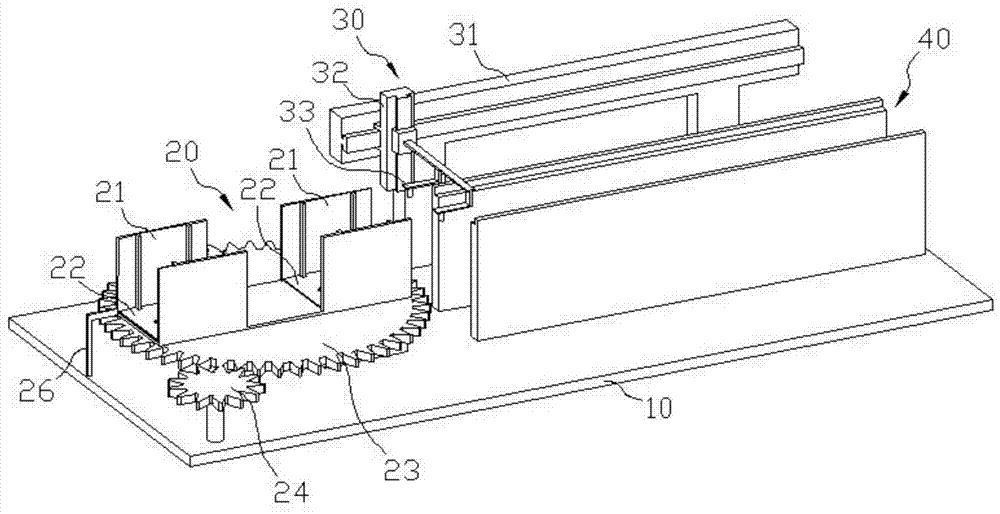

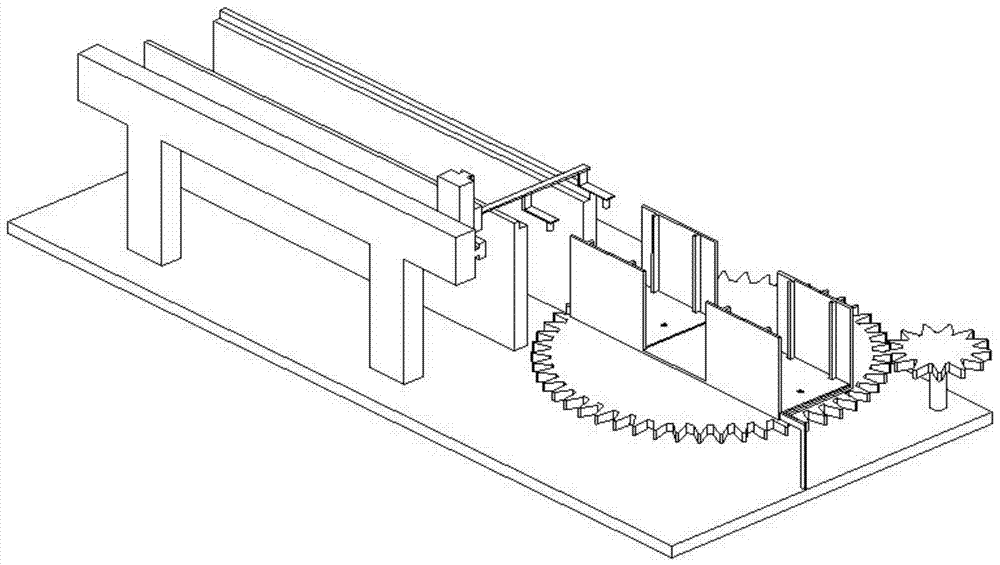

[0025] Such as figure 1 , a semi-automatic shoe material delivery equipment, including a base 10, a material stacking mechanism 20, a material taking mechanism 30, and a conveying mechanism 40, and the material stacking mechanism 20, the material taking mechanism 30, and the conveying mechanism 40 are all installed on the base 10 , the retrieving mechanism 30 is located on the side of the conveying mechanism 40, and the stacking mechanism 20 is located near the starting point of the conveying mechanism 40. start end.

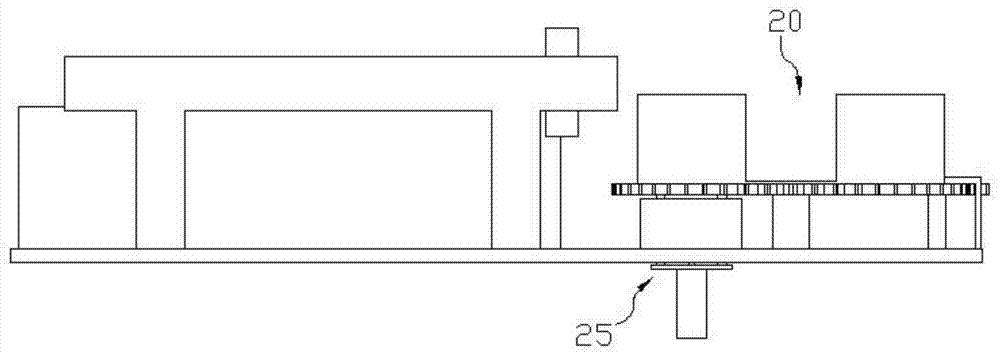

[0026] Such as figure 1 , the stacking mechanism 20 includes two bins 21 symmetrically arranged left and right, and a liftable tray 22 is arranged in the bins 21 . Two feed bins 21 are horizontally installed on the gear disc 23 arranged horizontally. The edges of the whole gear disc 23 are provided with teeth. The center lines coincide, and the symmetrical planes of the two feed bins 21 pass through the center line of the gear plate 23; combine image 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com