A shrapnel ball mill

A ball mill and shrapnel technology, applied in grain processing and other directions, can solve the problems of limited gravity of grinding media, limited impact force, limited material grinding level, etc., and achieve the effect of solving inability to grind, quickly throwing, and improving grinding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

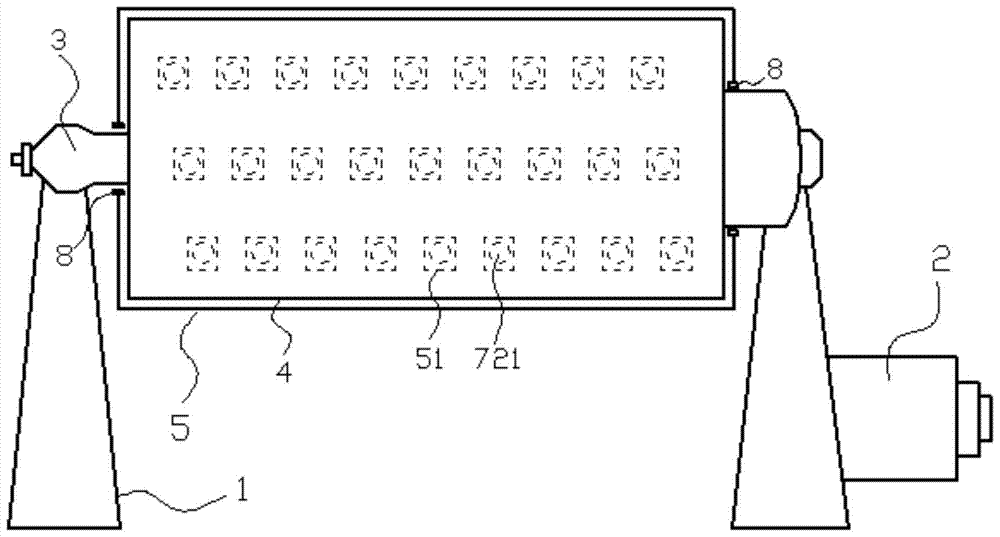

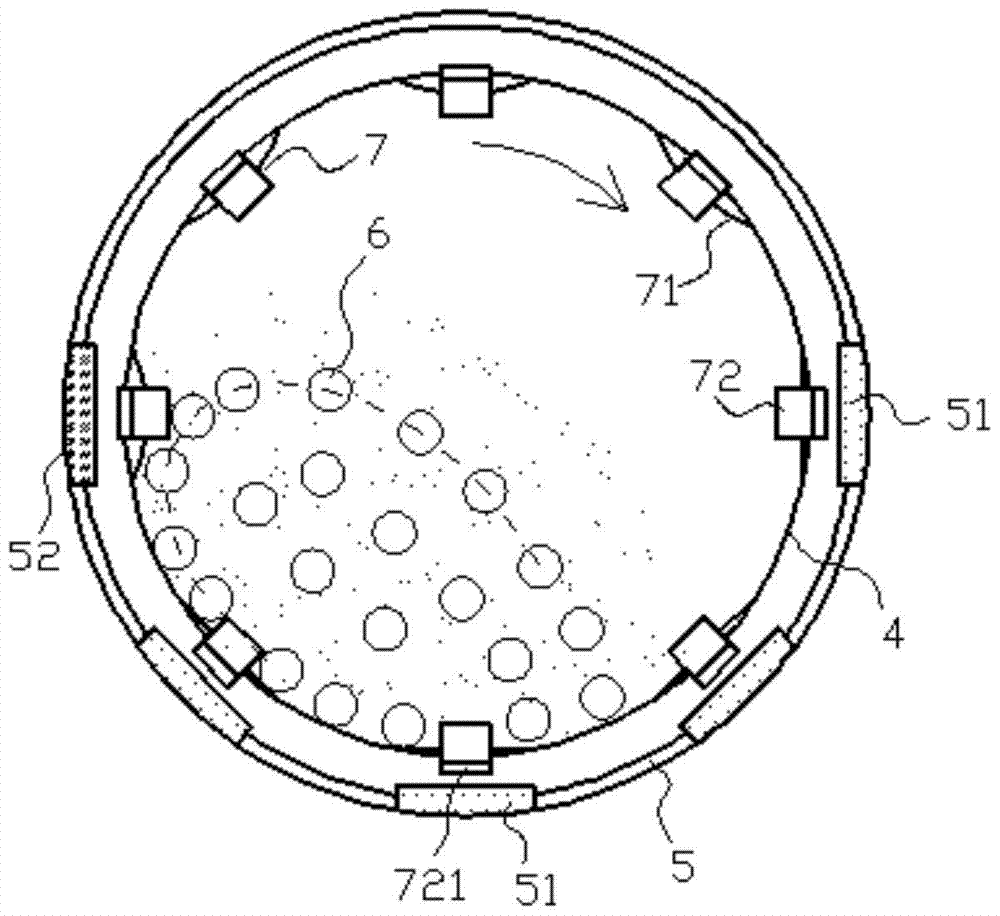

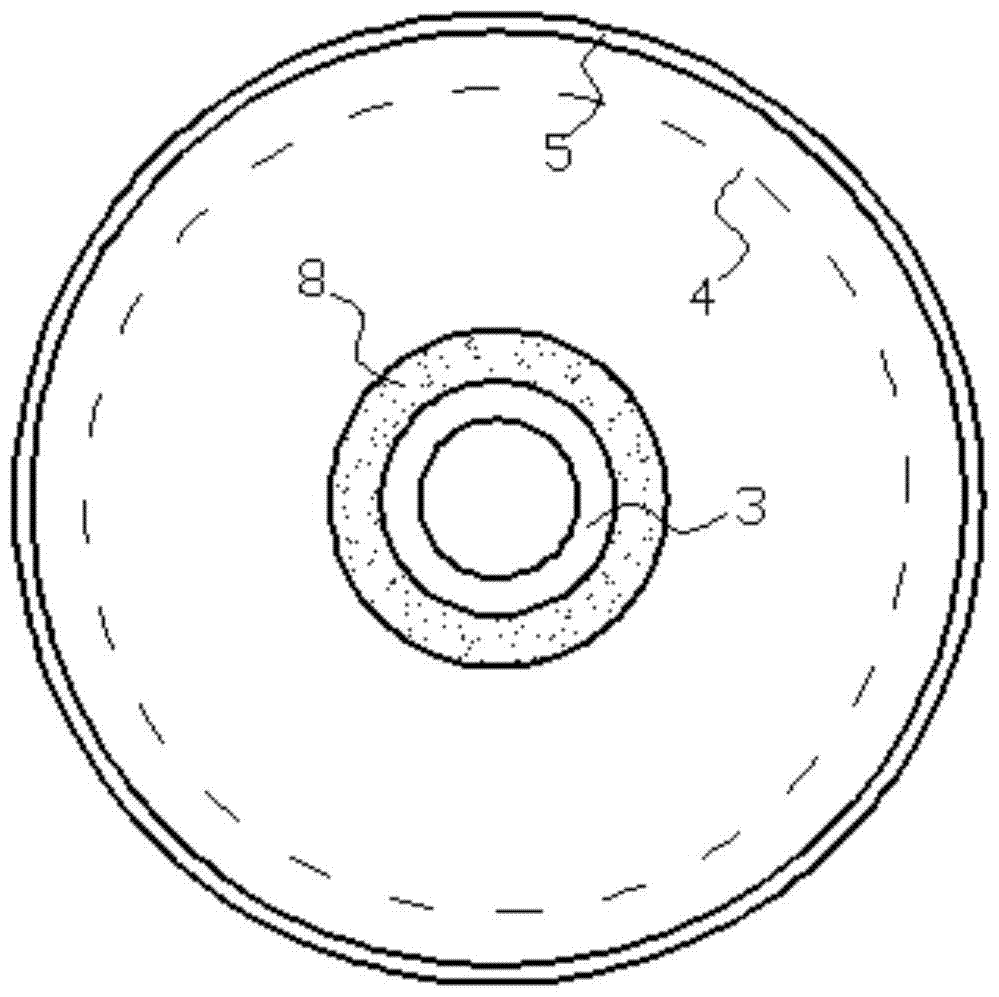

[0014] exist Figure 1 to Figure 3 In the shown embodiment, the shrapnel ball mill mainly includes a frame 1, a drive motor 2, a bearing 3, a tank body 4, a housing 5 and a grinding medium 6; On the frame 1, the tank body 4 is driven by the drive motor 2 and rotates around the bearing 3; the grinding medium 6 is filled inside the tank body 4; The housing 5 on the upper; the housing 5 is pivotally connected to the bearing 3 and can rotate along the bearing 3; as image 3 As shown, an elastic damping ring 8 is sheathed at the connection between the bearing 3 and the housing 5; the elastic damping ring 8 can effectively weaken the vibration of the housing 5 and increase the friction between the housing 5 and the bearing 3; After the angle of the housing 5 is adjusted, the housing 5 can be effectively prevented from changing its position; the housing 5 and the tank body 4 can rotate relatively independently; an elastic mechanism 7 is installed on the inner peripheral wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com