Industrial cleaning device

An industrial cleaning and cleaning liquid technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of bulky nozzle plates, slender and fragile structural design, poor maintenance, etc. Check and unblock functions, improve stability and maintainability, eliminate ergonomic issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

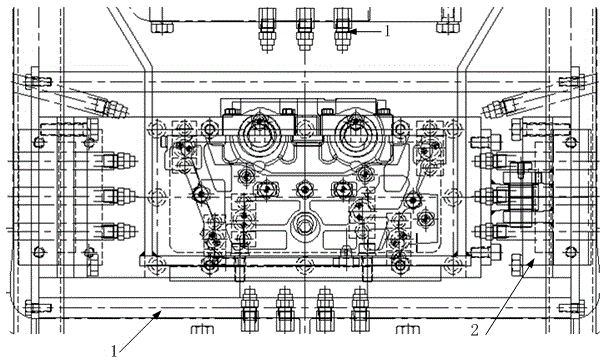

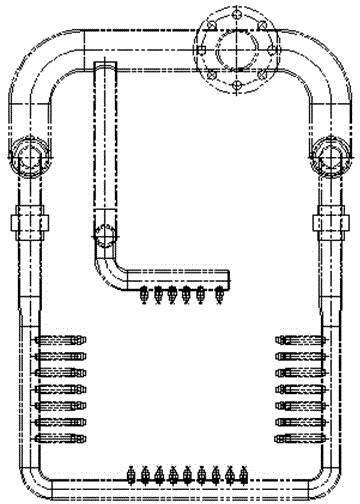

[0017] figure 1 Shown is the industrial cleaning device provided by the present invention, the industrial cleaning device includes a bracket, a plurality of nozzle plates 2, a first nozzle plate 2, a first air pressure valve, a medium-pressure cleaning liquid pipeline and several nozzles 1, and the plurality of nozzle plates The nozzle plate 2 and the first nozzle plate 2 are both arranged on the bracket to form a closed cavity, one end of the first nozzle plate 2 is movably connected with the bracket, and the first nozzle plate 2 is opened and closed along the articulated connection , a plurality of nozzles 1 are arranged on the nozzle plate 2 and the first nozzle plate 2 and placed in the cavity, the medium-pressure cleaning liquid pipeline is arranged on the bracket, and the medium-pressure cleaning liquid pipeline One end of each of the nozzle plates and the first nozzle plate 2 is respectively connected, and the other end of the medium-pressure cleaning liquid pipeline is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com