Dynamic constant thickness ratio taper control method

A technology of equal thickness and wedge shape, which is applied in the direction of rolling force/roll gap control, etc., can solve the problems of rolling breakage, feedback control lag, rack wave shape, etc. The effect of shaping and rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

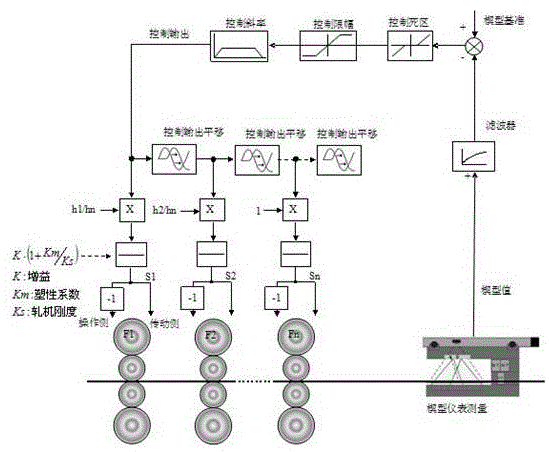

[0017] A dynamic constant thickness ratio wedge control method, as shown in the appendix figure 1 As shown, 1) The real-time wedge value W obtained after the meter at the exit of the finishing mill F7 detects the strip wedge and delays it by 20 meters;

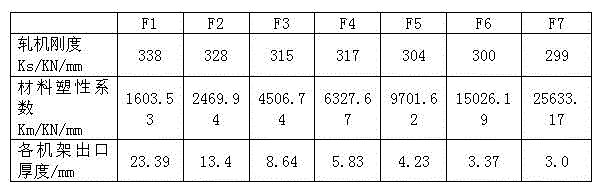

[0018] 2) After filtering, comparing with the reference value, controlling the dead zone and controlling the amplitude limit, the F1 outlet wedge W*H is calculated according to the thickness ratio 1 / H 7 , where H 1 , H 7 is the thickness of F1 and F7 outlet strip steel, so as to calculate the roll gap deviation adjustment amount K / (1+Km of F1 frame 1 / Ks 1 )* W*H 1 / H n *1 / 2, where K is the gain coefficient, generally 0.5-0.8, Km 1 is the plastic deformation coefficient of the F1 frame strip, Ks 1 is the stiffness coefficient of the F1 rolling mill;

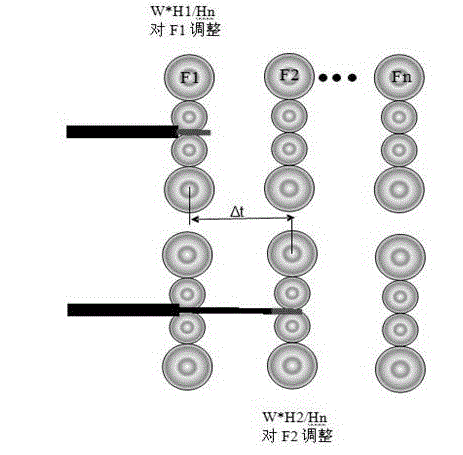

[0019] 3) As attached figure 2 As shown in the figure, when the strip, which has the effect of adjusting the roll gap deviation of the F1 frame by the wedge feedback...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com