Lithium battery pole piece punching and forming machine and its punching fine-tuning device

A technology of fine-tuning device and forming machine, which is applied in the direction of electrode manufacturing, forming tools, metal processing equipment, etc. It can solve the problems of reducing the service life of punching dies, high impact noise between punching dies and dies, and inconvenient adjustments. Achieve the effect of improving service life, precise punching and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

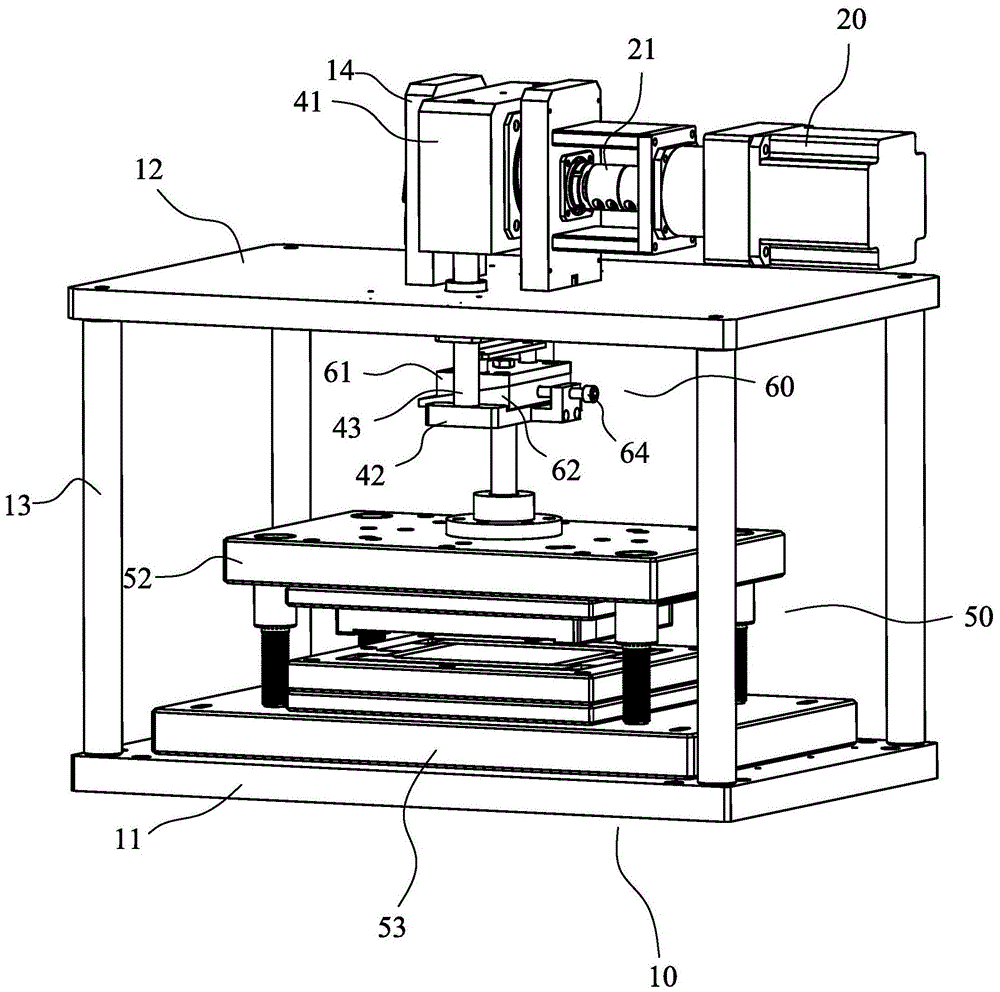

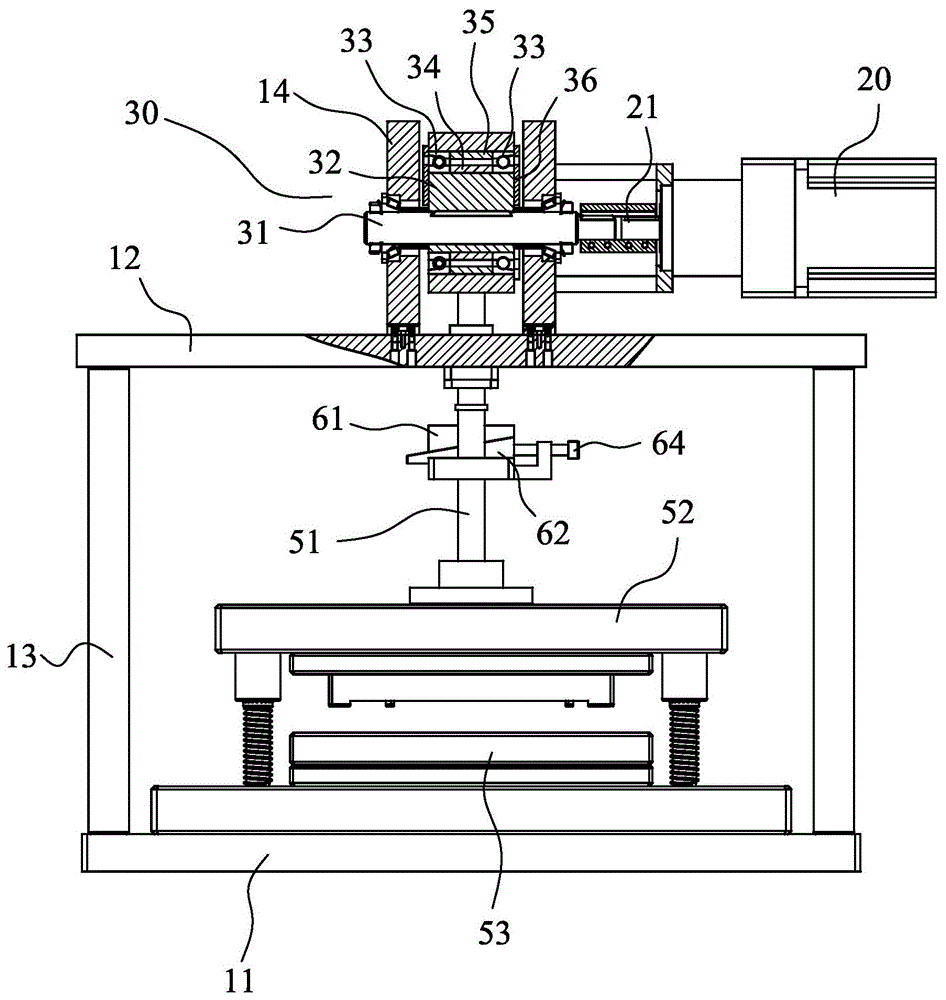

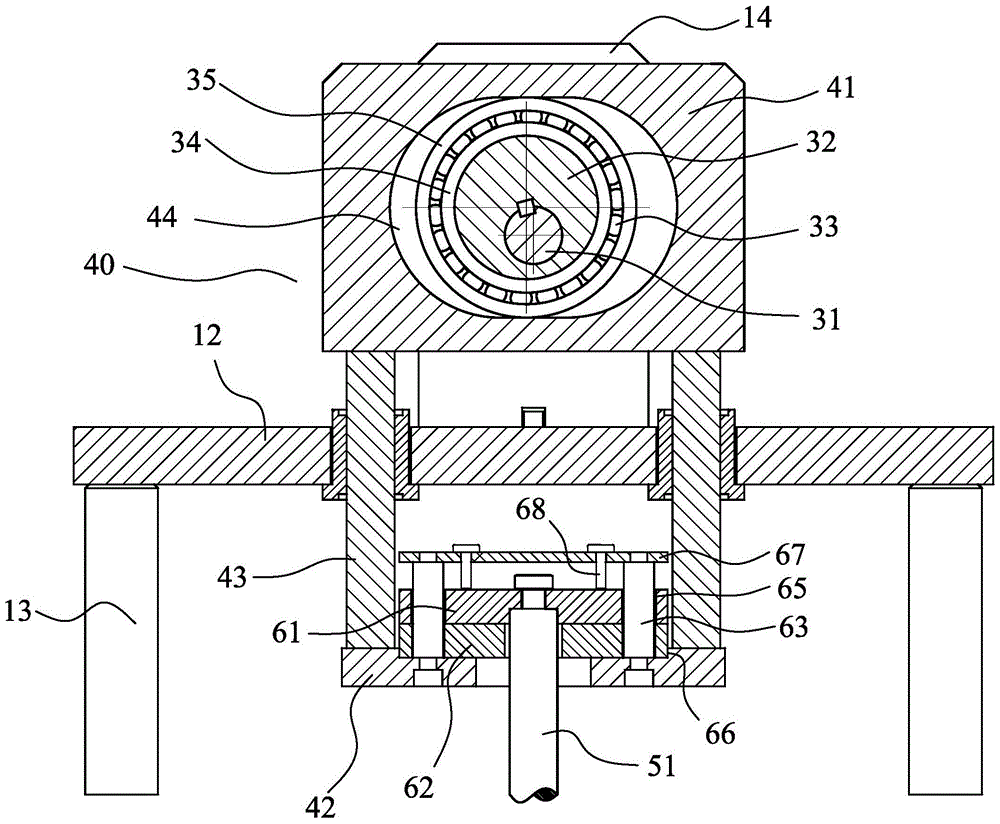

[0027] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the preferred embodiment of the present invention, a lithium battery pole piece die-cutting forming machine, including a frame 10, a driving device 20, a transmission mechanism 30, a lifting frame 40 and a die-cutting machine. Mold 50, punching die 50 has hanger bar 51, patrix 52 and lower die 53, and driving device 20 drives elevating frame 40, hanger bar 51 and patrix 52 lifting by transmission mechanism 30.

[0028] Wherein, the frame 10 includes a base plate 11, a top plate 12 and a plurality of uprights 13, the uprights 13 are connected between the base plate 11 and the top plate 12, and the top plate 12 is provided with vertical plates 14 on both sides for installing the transmission shaft.

[0029] The lifting frame 40 includes a sheave block 41 at the upper end, a seat plate 42 at the lower end and a plurality of longitudinally extending slide bars 43, the sheave block 41 is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com