Auxiliary drilling device for integrated circuit board

A technology for integrated circuit boards and drilling devices, which is applied to printed circuits, printed circuit manufacturing, electrical components, etc. It can solve the problems of inconvenient waste, turning holes, and unable to collect circuit boards, etc., and achieve the effect of maintaining stability and facilitating collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

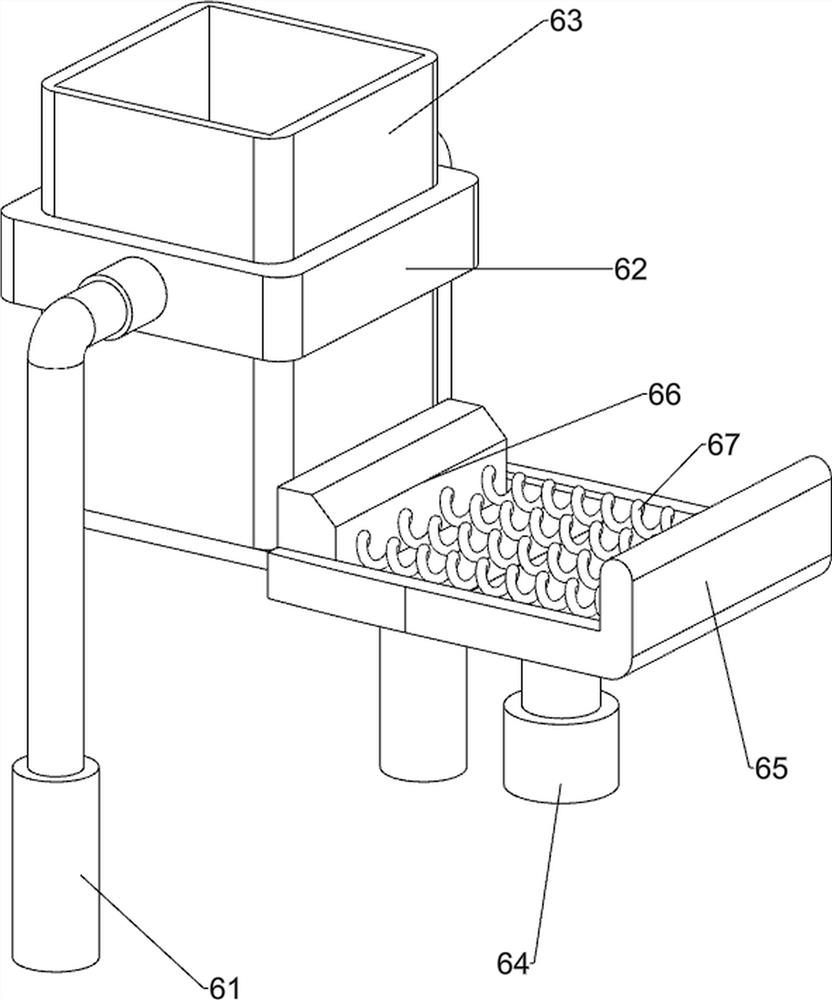

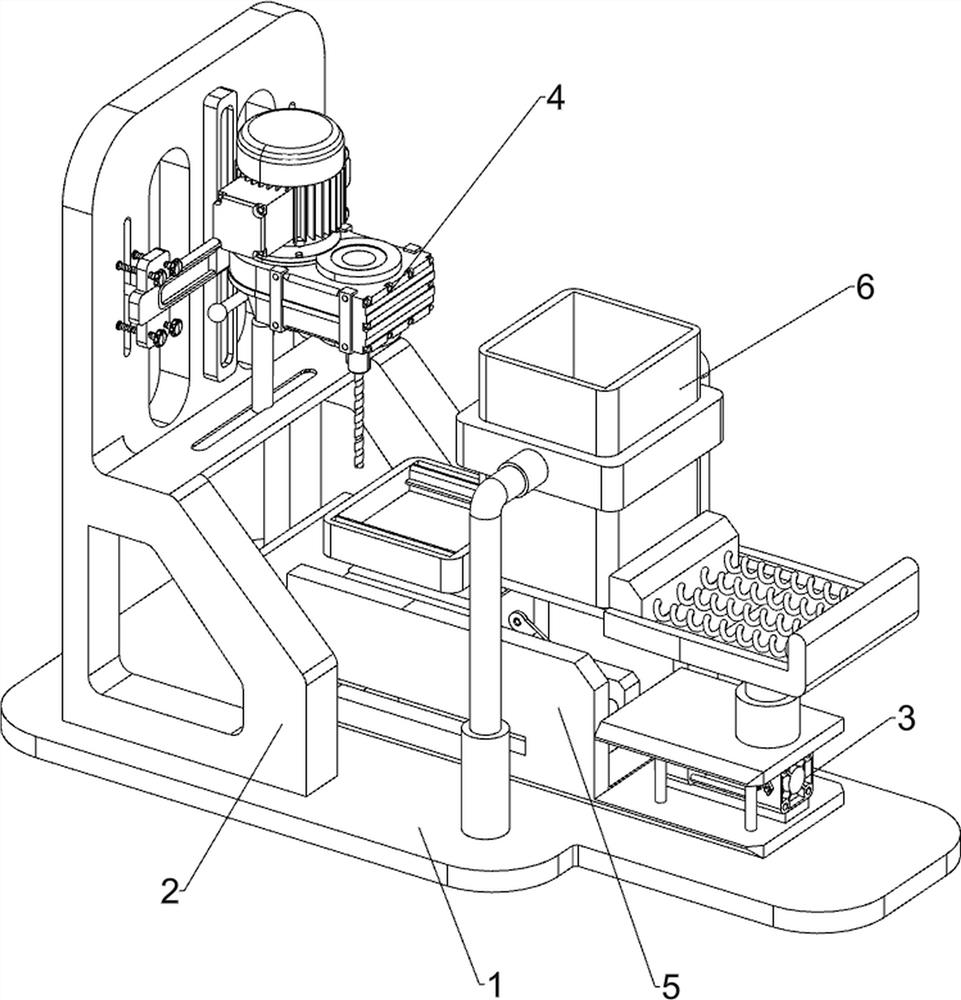

[0026] An integrated circuit board auxiliary drilling device, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a bottom plate 1, a workbench 2, a lifting mechanism 3, a punching mechanism 4 and a reciprocating feeding mechanism 5. A workbench 2 is provided on the left side of the top of the bottom plate 1, and a lifting mechanism 3 is provided on the bottom plate 1 and the workbench 2. , The lifting mechanism 3 is provided with a punching mechanism 4, and the bottom plate 1 is provided with a reciprocating feeding mechanism 5.

[0027] When people need to use this device, first people place the circuit board on the reciprocating feeding mechanism 5, and fix the circuit board, then people can start the punching mechanism 4 and the lifting mechanism 3, and the lifting mechanism 3 drives the reciprocating feeding mechanism 5 Operation, the reciprocating feeding mechanism 5 operates and then drives the circuit board to move upwards. When the circuit b...

Embodiment 2

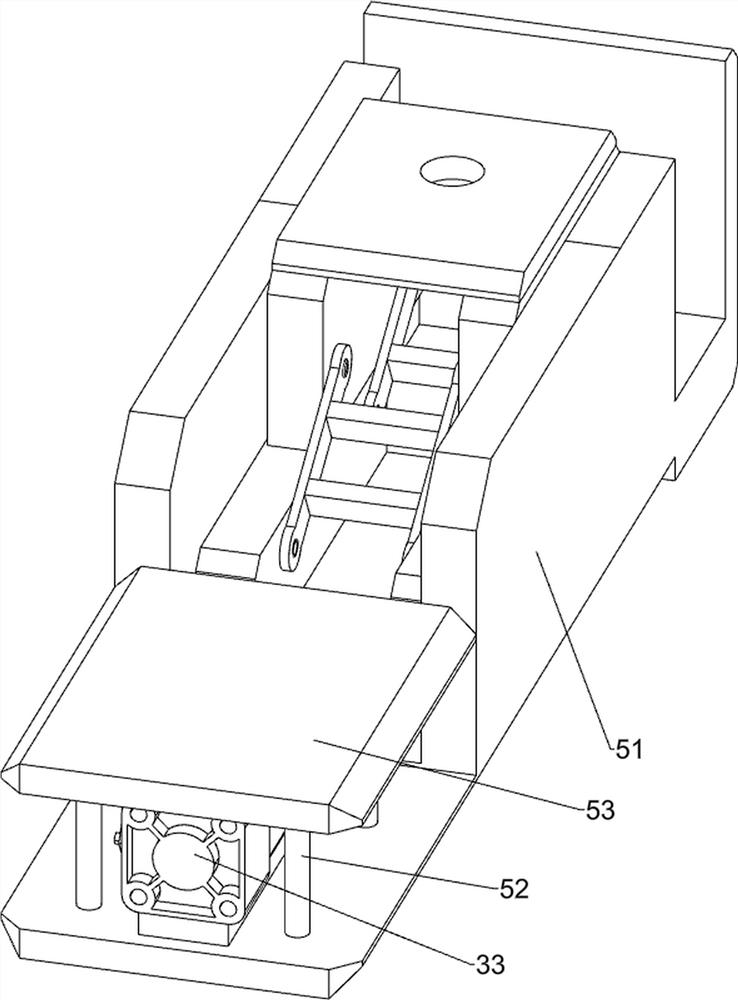

[0029] On the basis of Example 1, such as figure 1 , Figure 5 , Figure 6 and Figure 7 As shown, the lifting mechanism 3 includes a lifting rod 31, a first guide sleeve 32 and a cylinder 33, the first guide sleeve 32 is slidably provided on the workbench 2, the lifting rod 31 is slidably provided on the first guide sleeve 32, and the bottom plate 1 top right side is provided with cylinder 33.

[0030] The punching mechanism 4 includes a servo motor 41, a gearbox 42, a second guide sleeve 43, a threaded punch 44, a support rod 45 and a first fixed plate 46. The elevating rod 31 is provided with a gearbox 42, and the gearbox 42 is installed There is a servo motor 41, a second guide sleeve 43 is provided on the output shaft of the transmission case 42, a threaded punch 44 is provided on the second guide sleeve 43, a support rod 45 is symmetrically provided on the transmission case 42, and a second guide sleeve 43 is provided on the transmission case 42. A fixed plate 46.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com