Die base of stamping press and stamping press

A technology of a die base and a punching machine, applied in the field of punching equipment, can solve problems such as time-consuming, inconvenient replacement, affecting production, etc., and achieve the effect of improving processing efficiency and changing the die quickly and easily.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

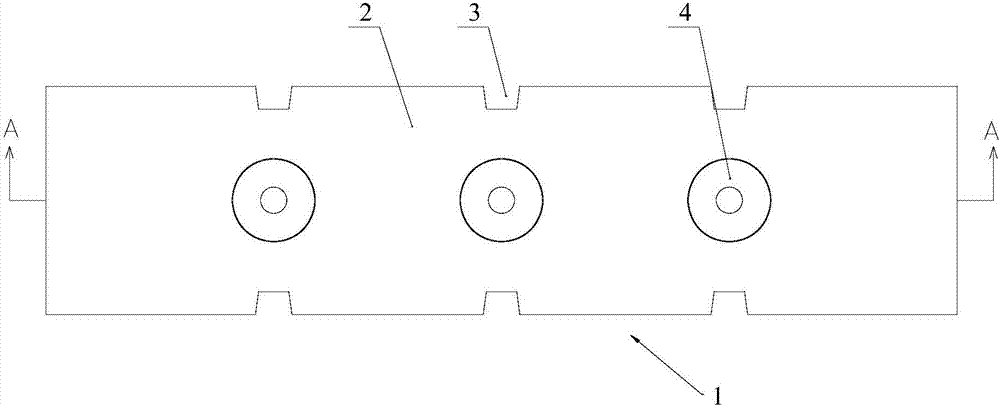

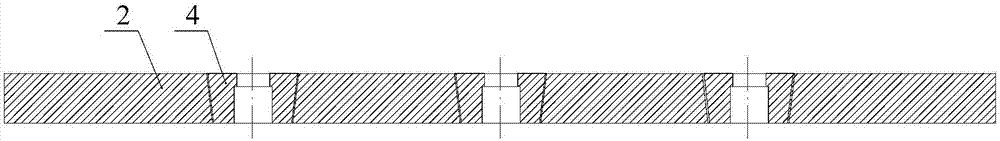

[0041] Such as figure 1 and 2 As shown, a die base 1 of a stamping machine includes a body 2. The body 2 has a plurality of die grooves, and each die groove is equipped with a die 4 of different sizes, and the axes of each die groove are located at the same on flat surface.

[0042] In this embodiment, the main body 2 is strip-shaped, and the two long side walls of the main body 2 have card slots 3; The distance is the same as the distance between two adjacent die grooves. Setting the card slot 3 can facilitate the positioning and fixing of the main body 2 after it is moved into place.

[0043] Multiple dies 4 are installed on the die base 1 at the same time. When processing the same aperture, the diameter of the cutting edge of the die 4 is determined according to the thickness range of the sheet to be processed. At this time, only the body 2 needs to be moved so that the corresponding die 4 slide to the position of the center line of the hydraulic shaft, and the punching...

Embodiment 2

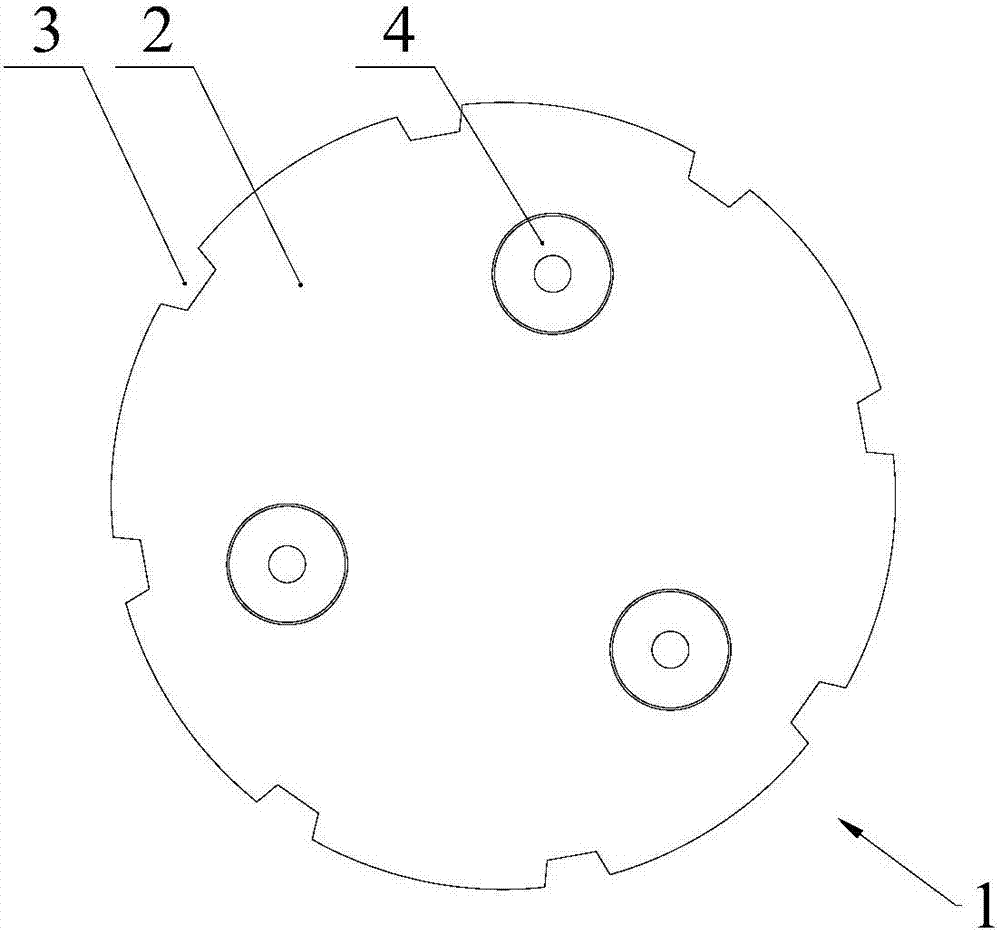

[0045] Such as image 3 As shown, a die base 1 of a stamping machine includes a body 2, and the body 2 has a plurality of die grooves, each die groove is arranged around the axis of the body 2, and the distance between the axis of each die groove and the axis of the body 2 is All are equal, and the die 4 of different size is installed on each die groove.

[0046] In this embodiment, the body 2 is cylindrical, and the die grooves are uniformly distributed around the axis of the body 2 , and a plurality of locking grooves 3 are evenly distributed on the outer wall of the body 2 along the circumferential direction.

[0047] Multiple dies 4 are installed on the base 1 of the die at the same time. When processing the same aperture, the cutting edge diameter of the die 4 is determined according to the thickness range of the sheet to be processed. At this time, only the body 2 needs to be rotated so that the corresponding die 4 slide to the position of the center line of the hydraul...

Embodiment 3

[0049] Such as Figure 4 As shown, a stamping machine includes:

[0050] Rack 11;

[0051] Die base 1, die base 1 is the die base in embodiment 1;

[0052] Push the switching mechanism, used to push the die base 1 to reciprocate relative to the frame 11;

[0053] The limit mechanism is used to limit the die base 1 after the die base 1 is moved into place.

[0054] In this embodiment, the push switch mechanism includes a switch cylinder 10 , and the piston rod of the switch cylinder 10 is fixed to the die base 1 .

[0055] In this embodiment, the body 2 is strip-shaped, and the two long side walls of the body 2 have card slots 3, and the die slots are arranged at equal intervals, and the card slots 3 are arranged at equal intervals, and the adjacent two card slots 3 The distance is the same as the distance between two adjacent die grooves;

[0056] Limiting mechanisms include:

[0057] The limit block 7 is slidably arranged on one side of the body 2, and the limit block 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com