A control method for a compound vibration control system of a continuous casting machine crystallizer

A technology of composite vibration and control system, applied in the field of continuous casting in the metallurgical industry, can solve problems such as robustness and instability, and achieve the effects of improving anti-interference performance and robustness, improving convergence speed, and improving production and use effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

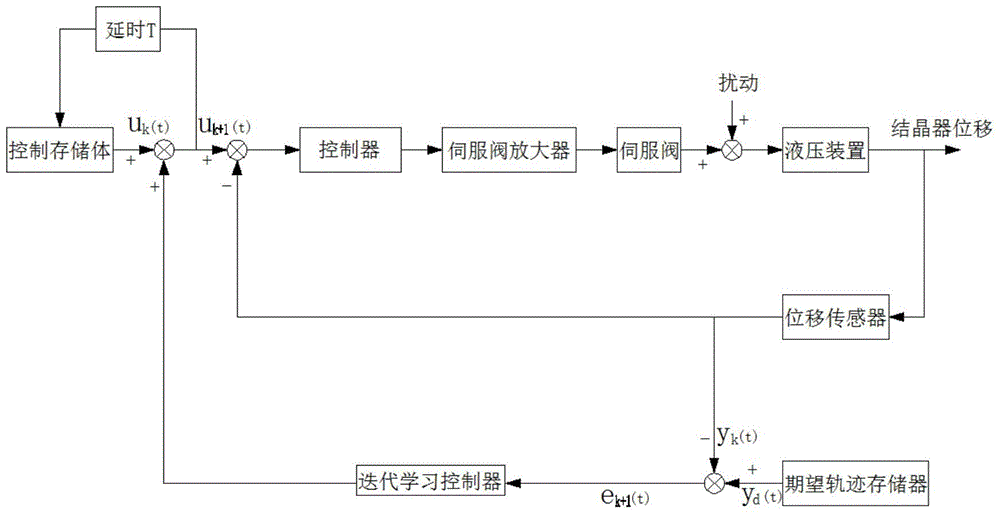

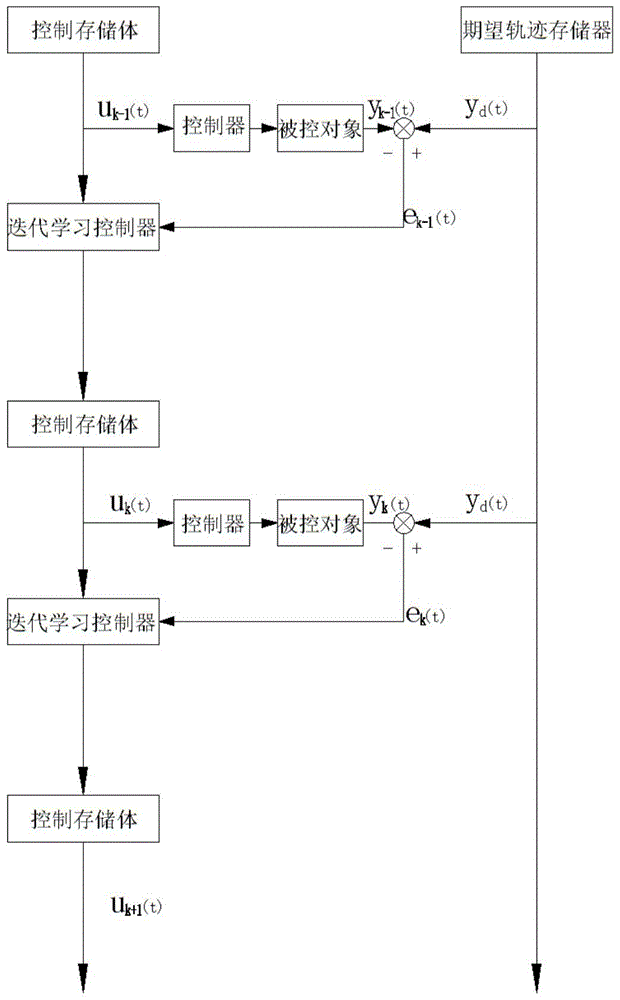

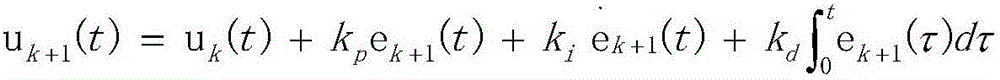

[0030] like figure 1 As shown, a composite control system of the crystallizer vibration system of a continuous casting machine includes an inner loop controller and an outer loop controller, and the inner loop controller and the outer loop controller form a double closed loop composite control system. The inner loop controller includes the controller, servo valve amplifier, servo valve, hydraulic device, and displacement sensor. The controller is a digital PID controller. Through the inner loop controller, not only the anti-interference performance and robustness of the system can be improved, It is beneficial to improve the convergence speed of iterative learning, and achieves a better production and use effect. The controller, servo valve amplifier, servo valve, hydraulic device, and displacement sensor are connected in sequence to form a closed loop. The servo valve amplifier, servo valve, and hydraulic device perform motion control on the mold of the continuous casting mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com