A welding line for the base of a checkered plate logistics vehicle

A logistics vehicle and welding line technology, which is applied in the field of welding lines, can solve problems such as low welding efficiency, high labor intensity of workers, and easy fatigue, and achieve the effects of improving welding efficiency, reducing labor usage, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

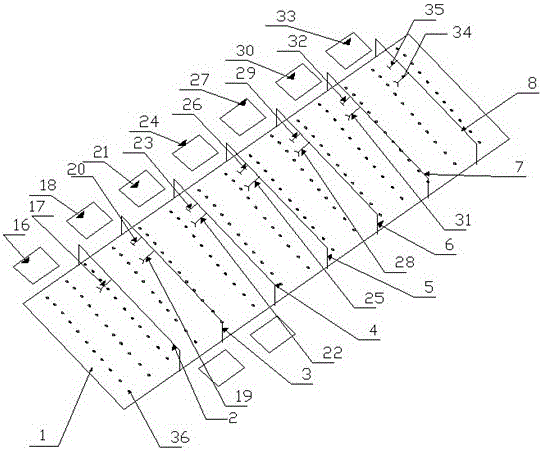

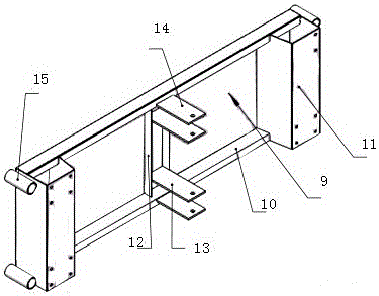

[0021] The present invention is a welding line for the checkered plate logistics vehicle base, and its main function is to complete the welding of various parts of the checkered plate logistics vehicle base. The welding sequence is: wheel fixed inner plate 13, wheel fixed outer plate 14, middle crosspiece 12 , Transverse tube 10, end plate 11 and armrest tube 15.

[0022] Therefore, the welding line we designed includes conveyor belt 1, panel conveying station 2, wheel fixed inner panel welding station 3, wheel fixed outer panel welding station 4, middle crosspiece welding station 5, horizontal tube welding station 6, End plate welding station 7 and armrest tube welding station 8, according to the running direction of the panel, the panel conveying station 2 is located in front of the wheel fixed inner panel welding station 3, and the wheel fixed inner panel welding station 3 is located on the wheel fixed outer panel In front of the welding station 4, the welding station 4 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com