Steam type crosslinking pool device for electric wires

A wire and cable, steam technology, applied in the direction of cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of reducing the service life of the cross-linked pool, increasing the workload of opening the pool cover, increasing the floor area of the equipment, etc., to reduce heat Dissipation, reduction of energy consumption, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

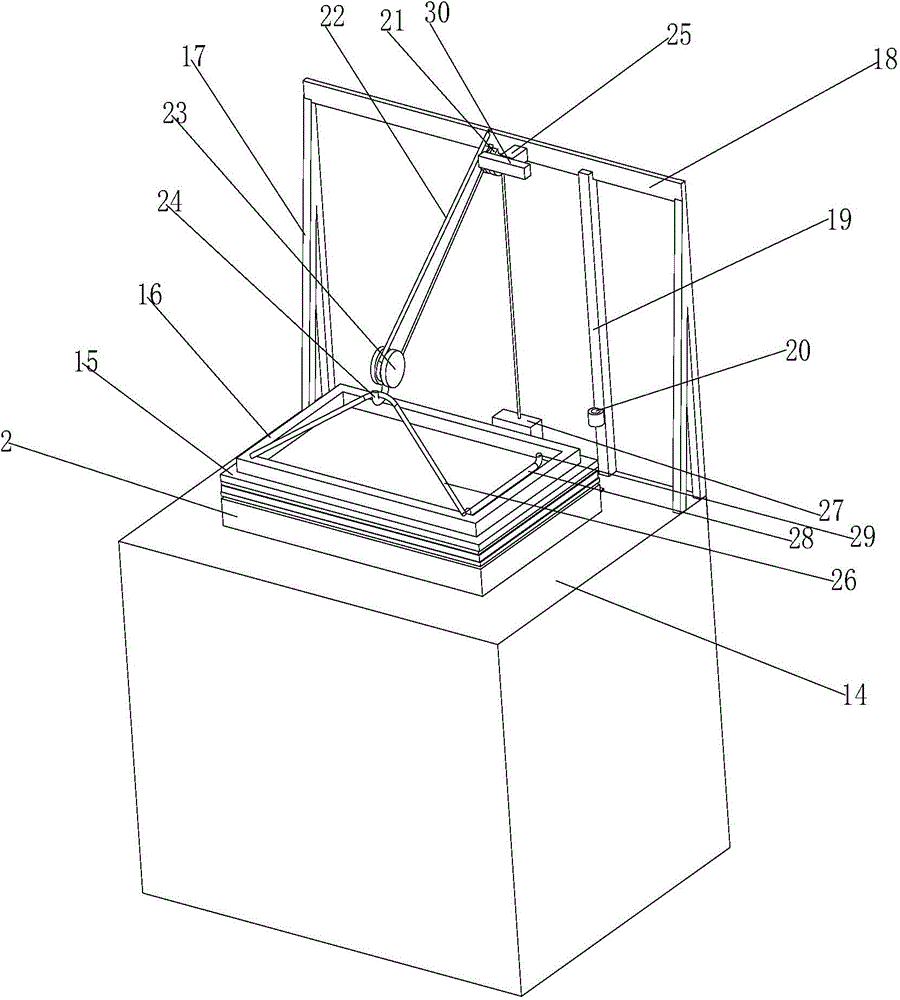

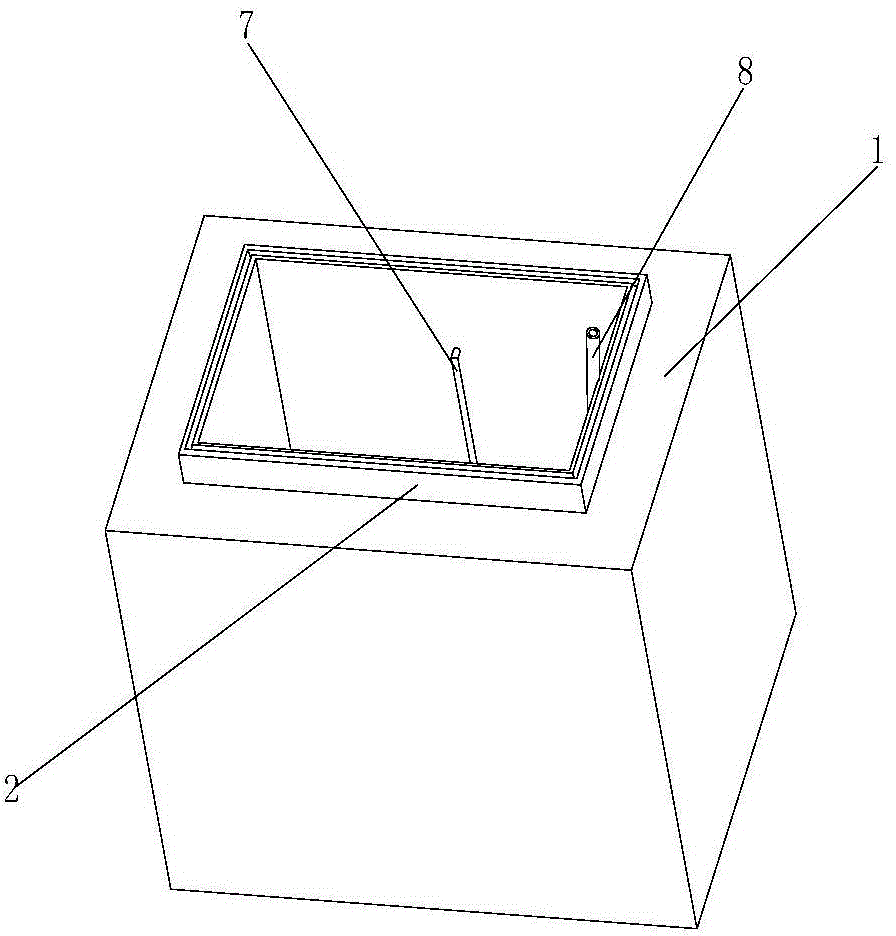

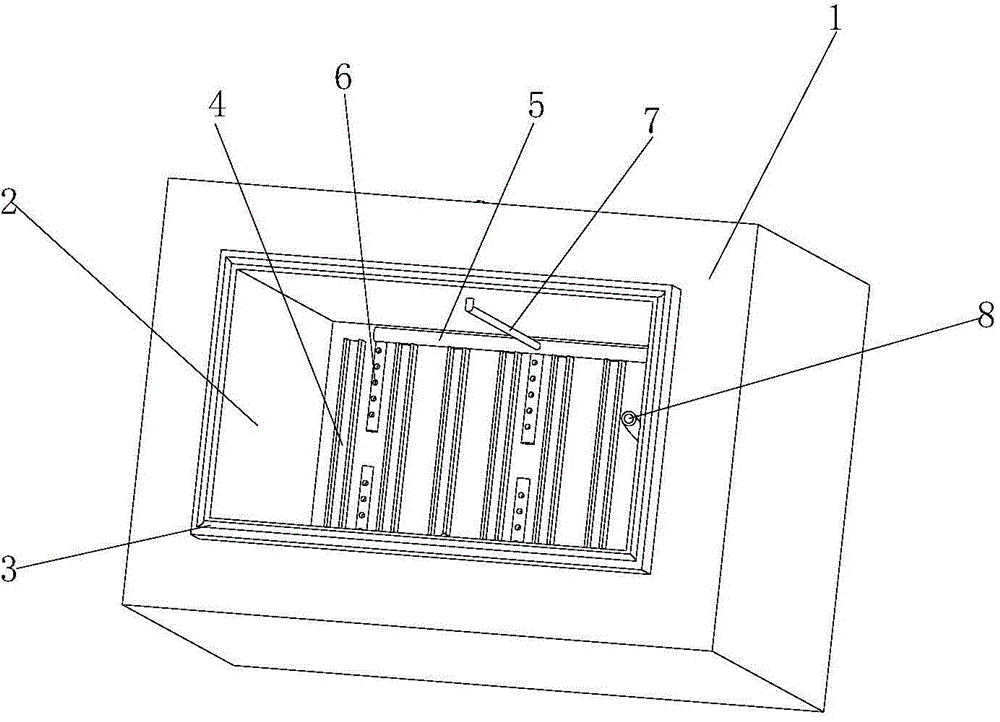

[0048] As shown in the figure, the present invention provides a wire and cable steam type crosslinking pool device, including a pool body and a cover body 15, the pool body is a sunken structure buried in the ground, and an electric heating steam boiler (not shown in the figure) is also included. ) and cover body control unit, steam supply adopts electric heating steam boiler, no other energy supply is needed, it is convenient to install and use on the production site, the pool body includes outer layer 1, inner layer 2 and bottom, inner layer 2 and outer layer 1 Form a "back" font structure;

[0049] The outer layer 1 is a concrete structure, the inner surface of the outer layer 1 has a waterproof layer, and the top surface of the outer layer 1 is flush with the ground 14 to reduce manufacturing costs;

[0050] The inner layer 2 is a concrete structure, the inner surface of the inner layer 2 has a waterproof layer, the top surface of the inner layer 2 is higher than the groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com